Concept Development

This is potentially the most important stage of the design process and covers such a wide range of skills. On this page I will go through individual elements of some of my projects that I feel best show off my wide range of development skills, these will include: modelling skills, user studies, materials/manufacturing development and much more…

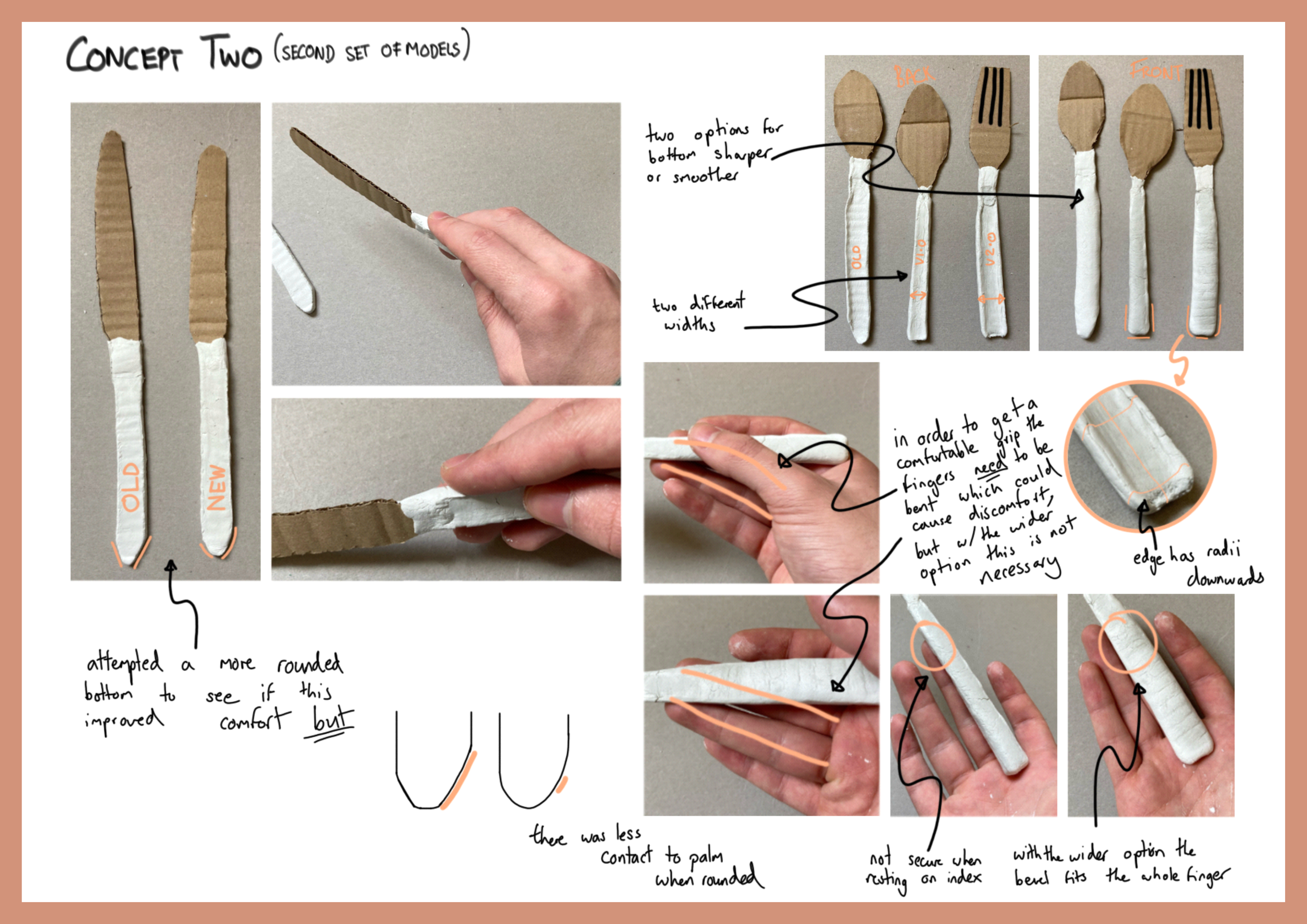

Denteler Cutlery Range

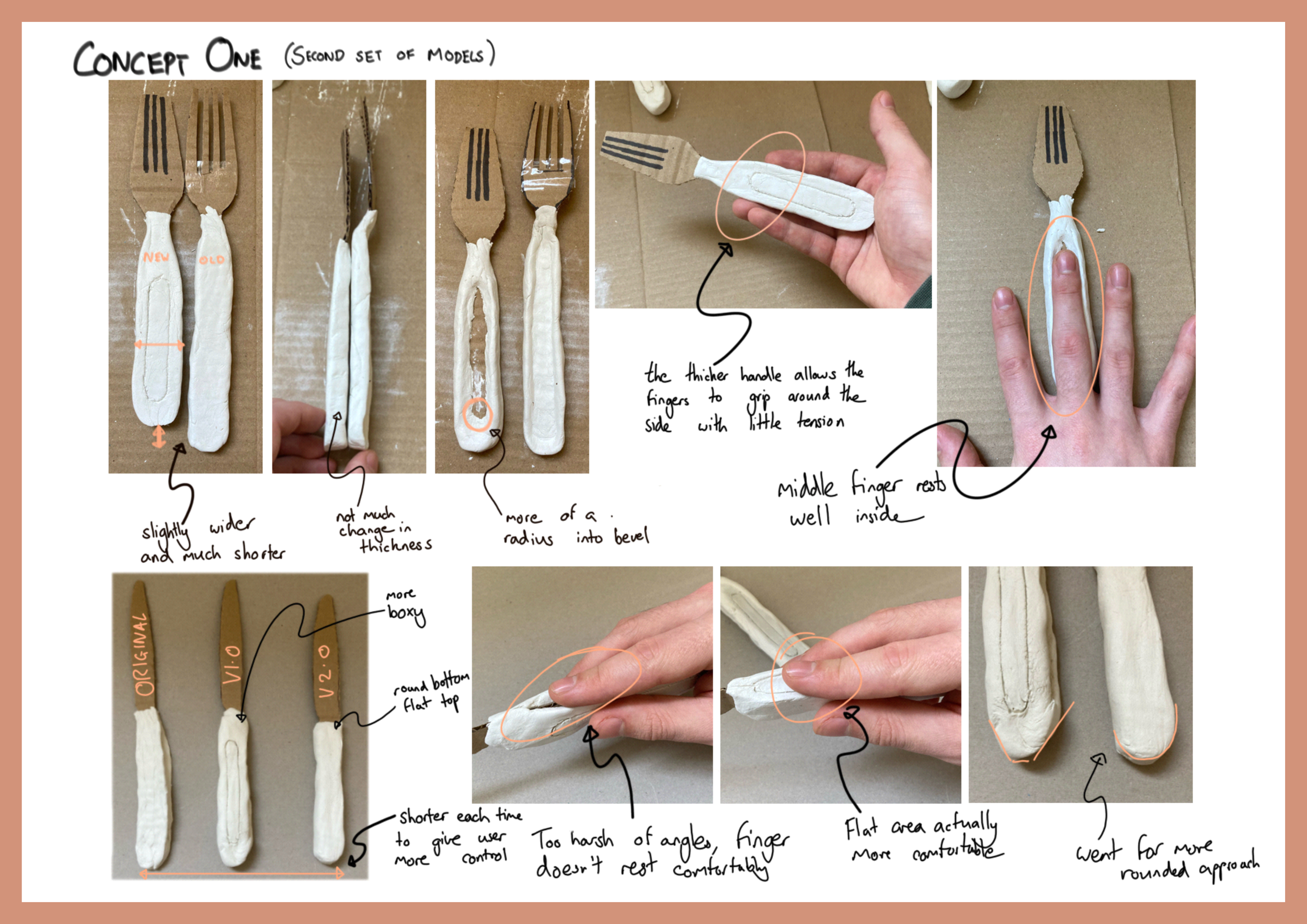

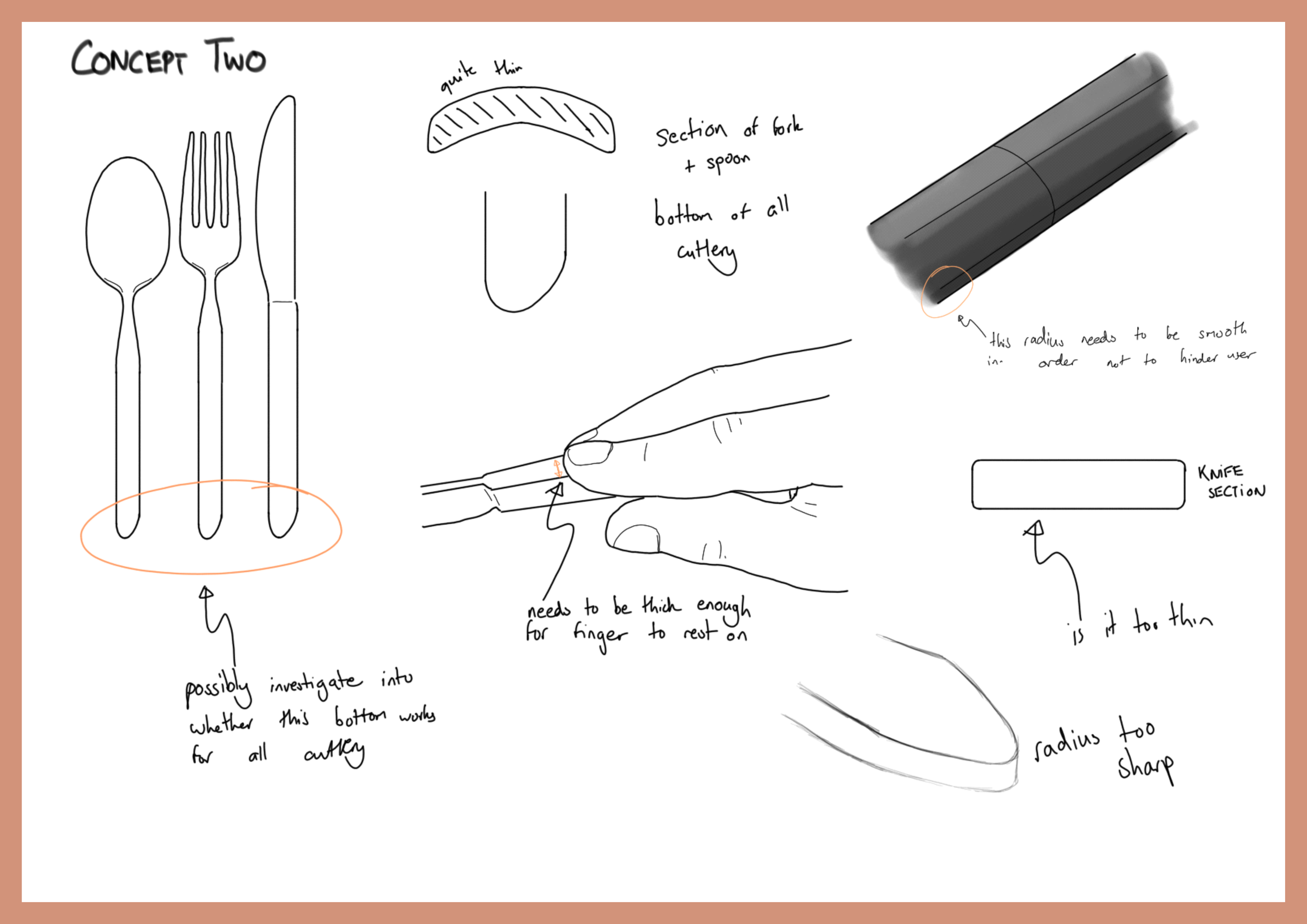

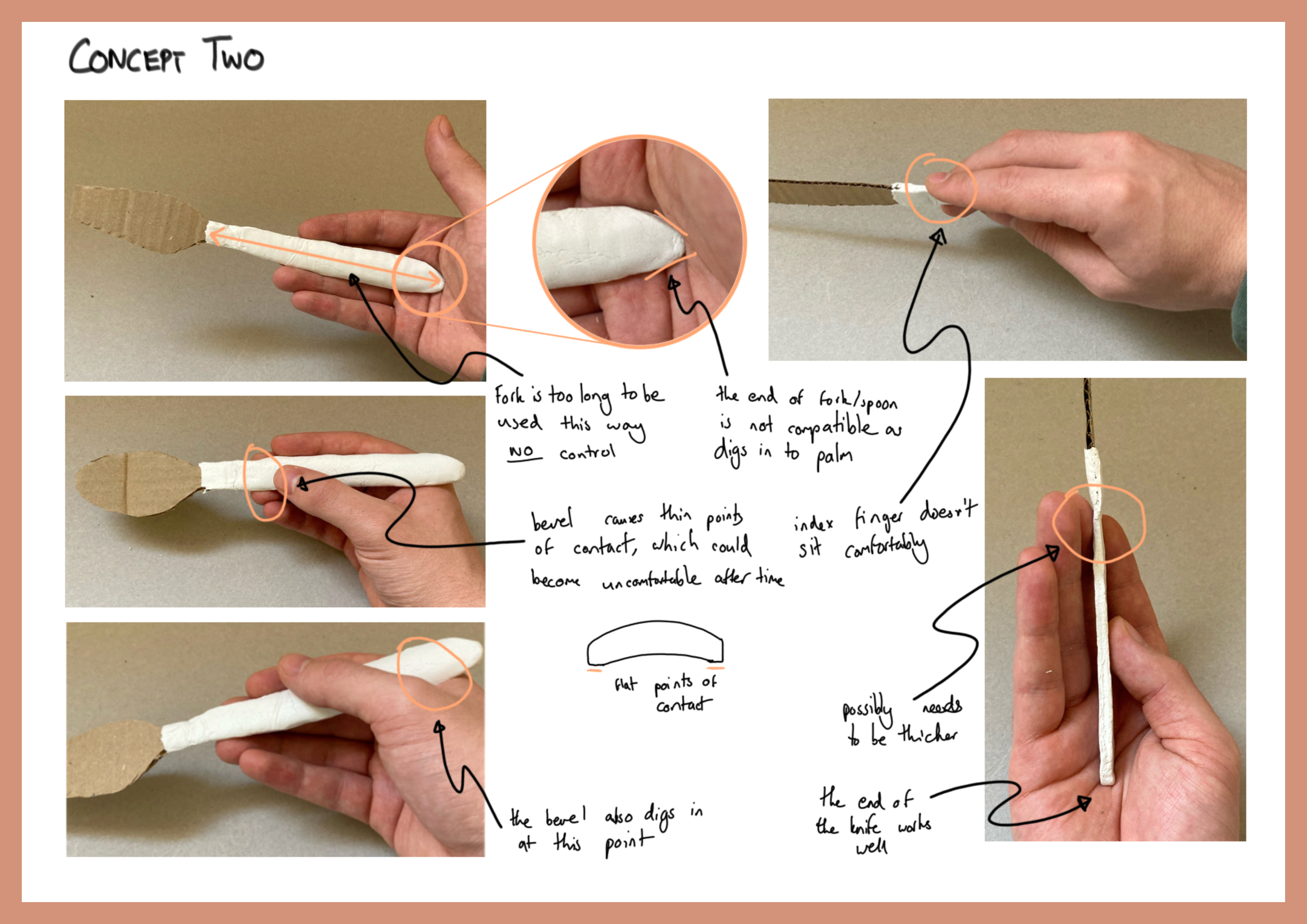

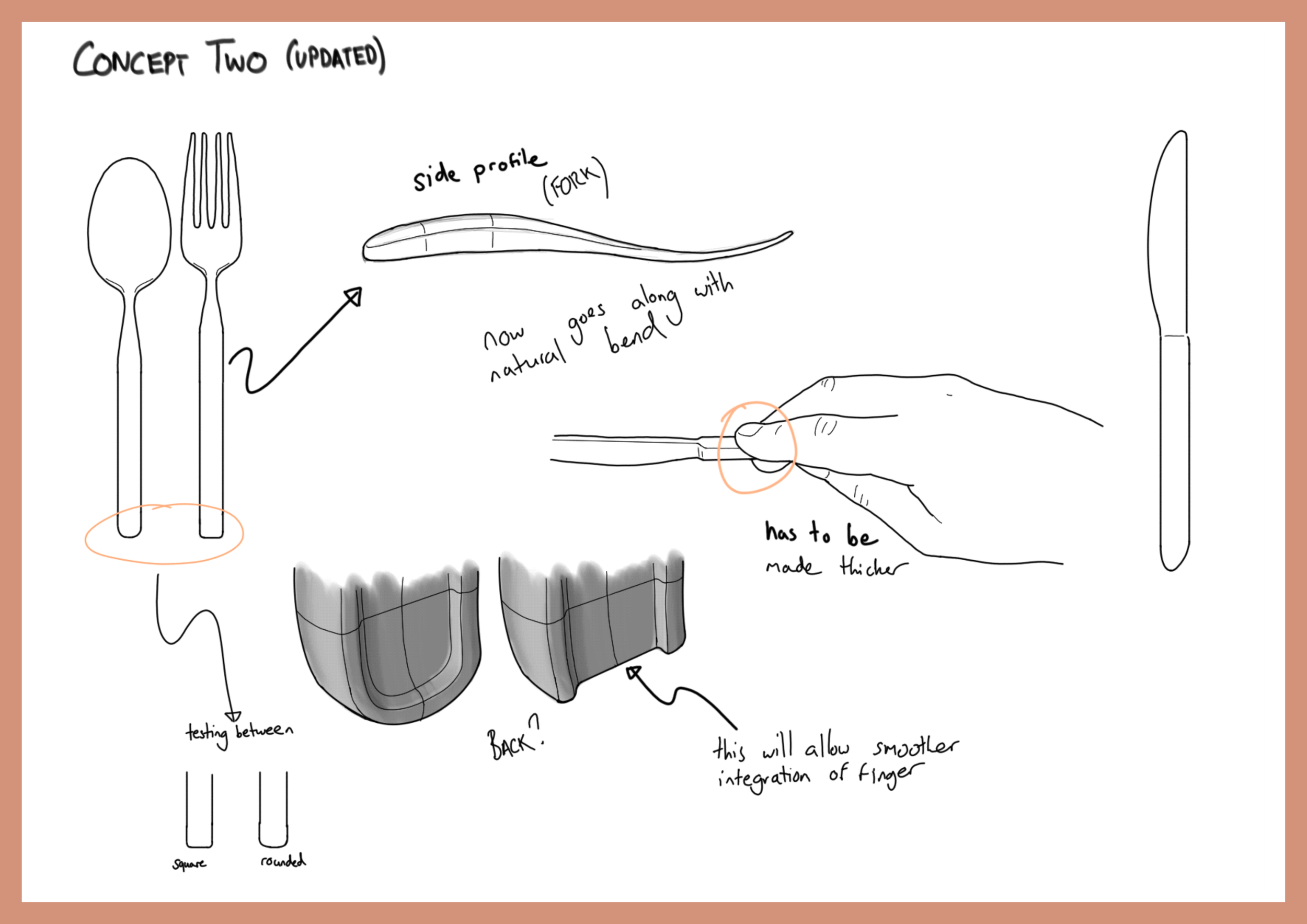

The two development skills I want to show off from this project are an empathy study and the use of clay modelling.

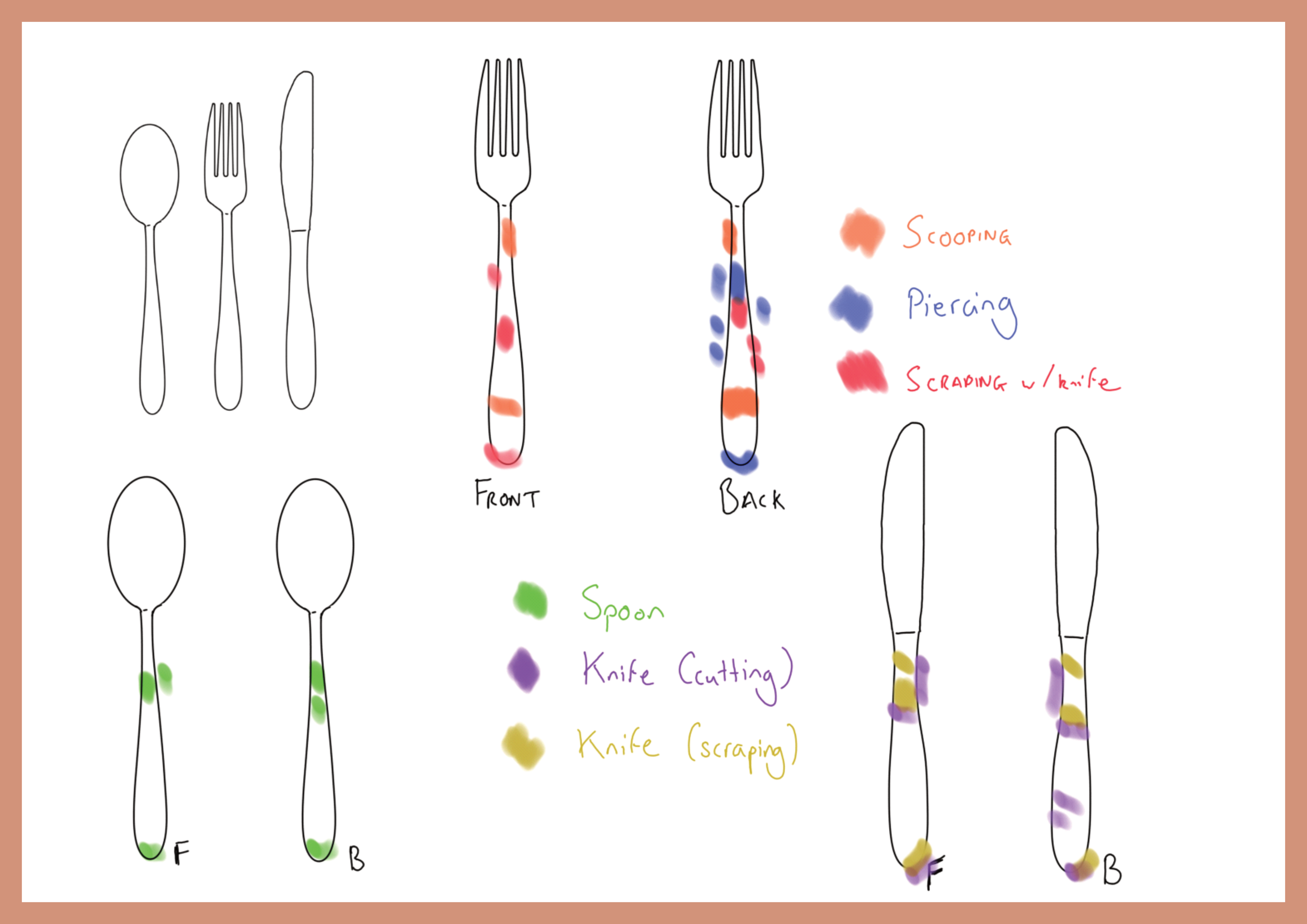

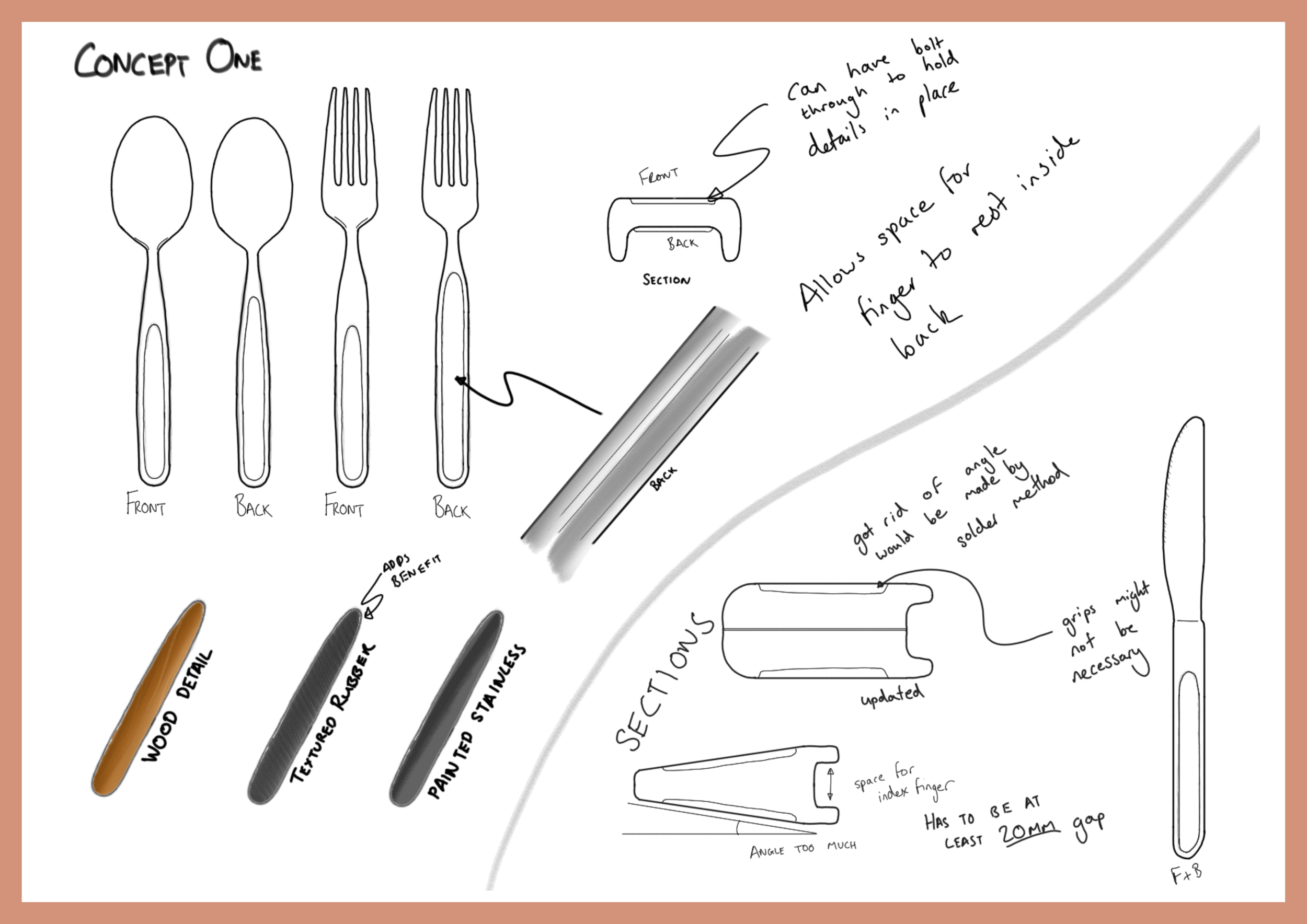

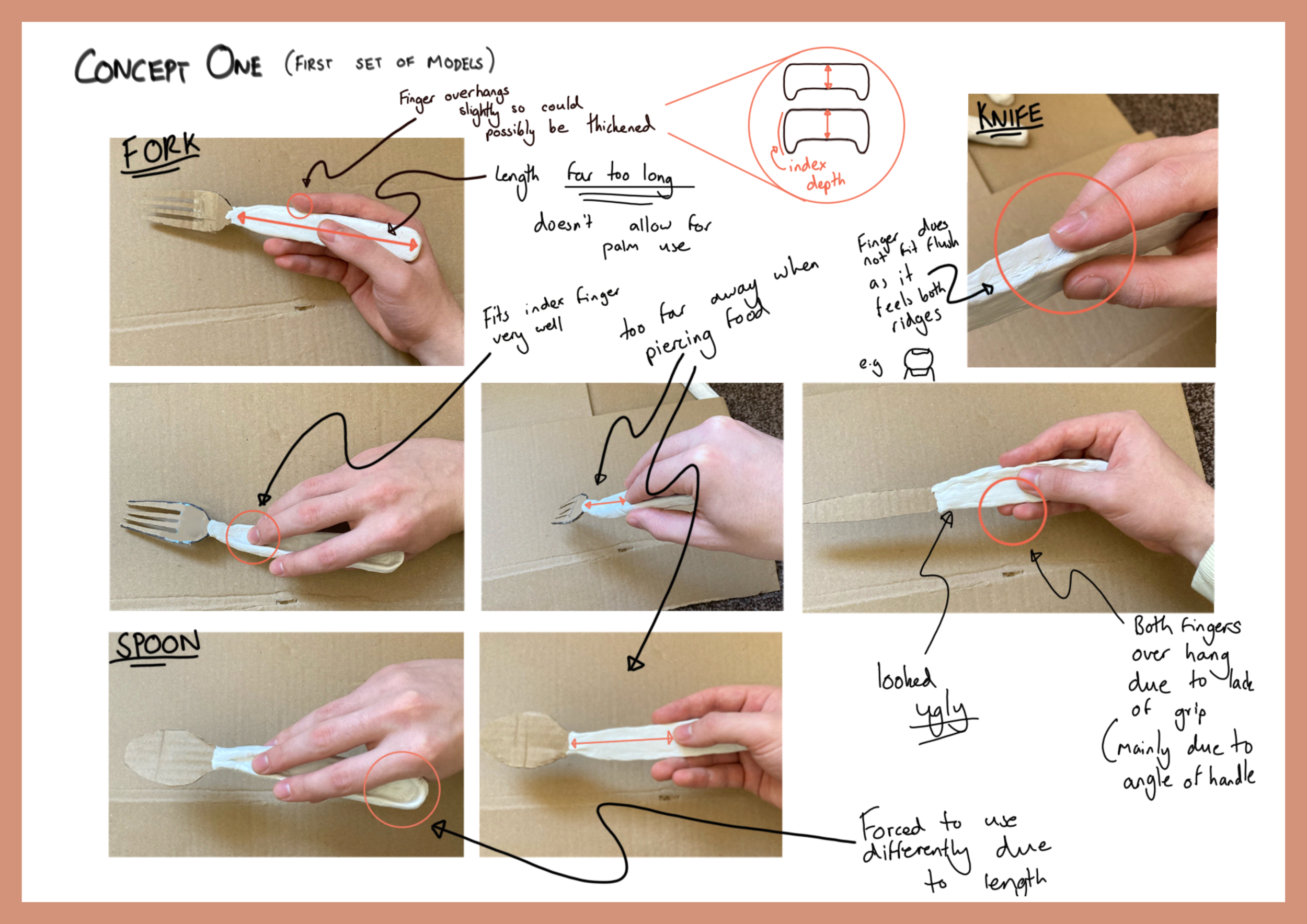

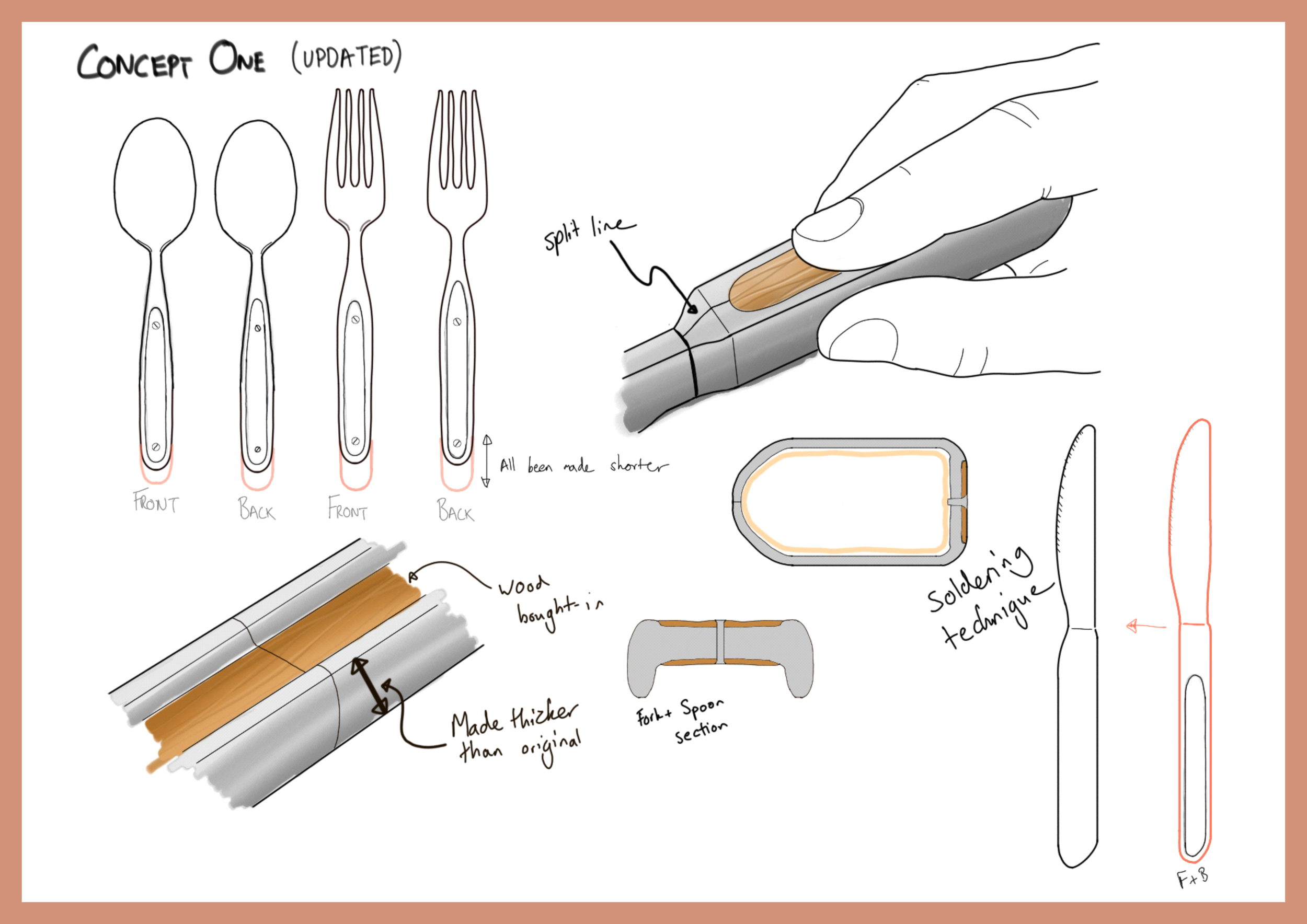

The empathy study was done near the beginning of the process and was vital in helping me develop the physical ergonomic features of the design. The clay modelling continued on this path, whilst giving me the instant feedback I needed on how my concepts were developing and what changes were necessary…

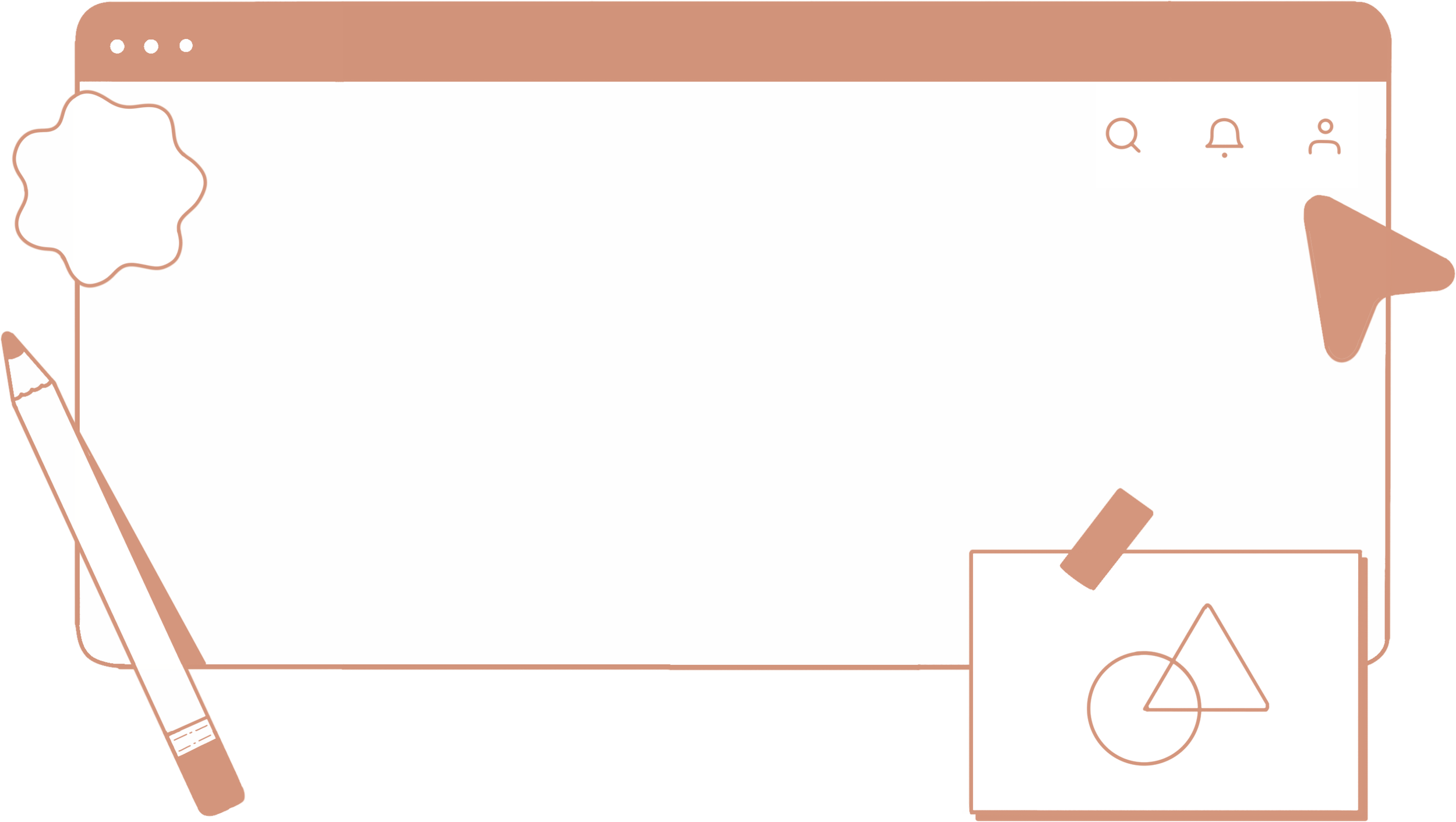

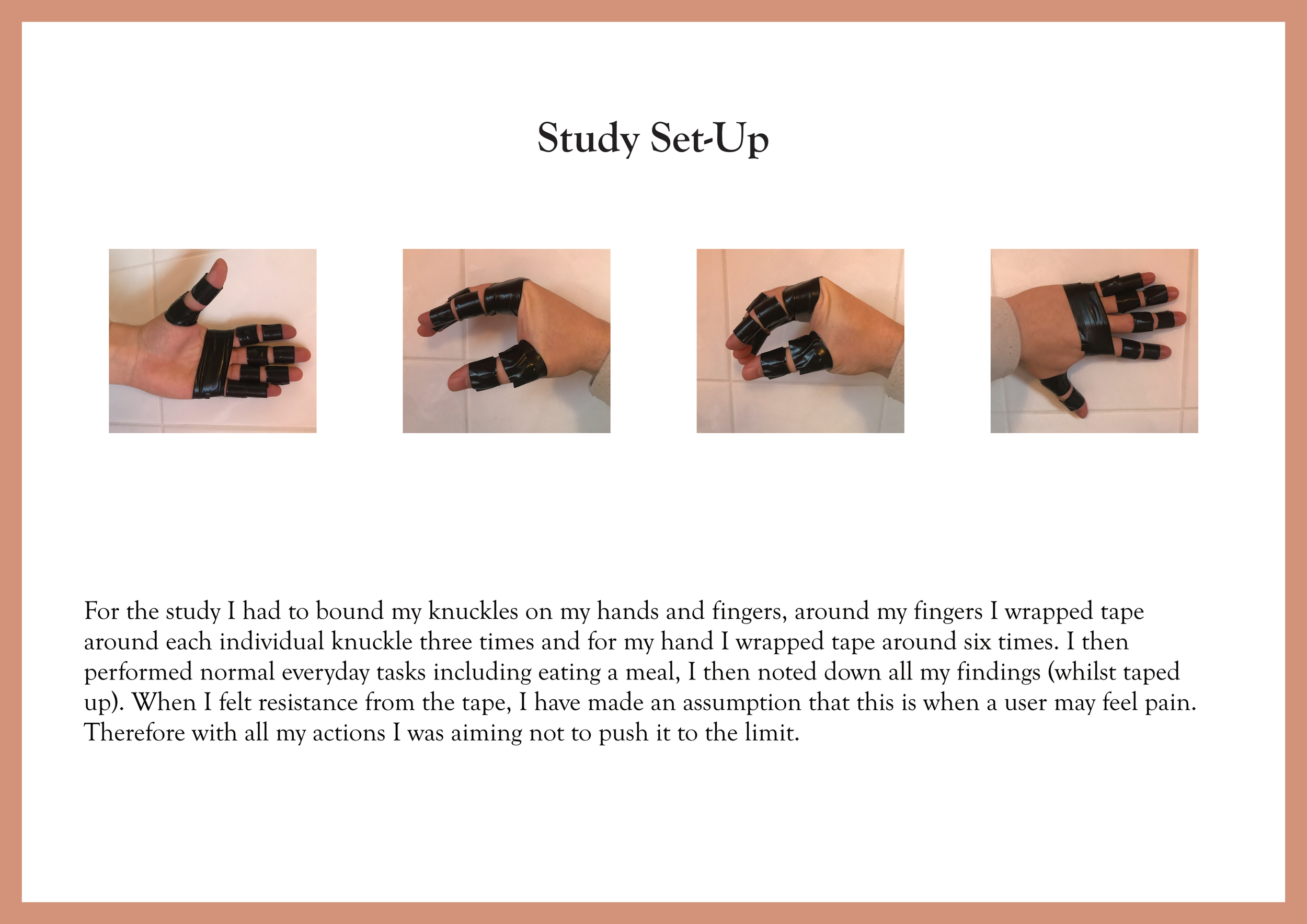

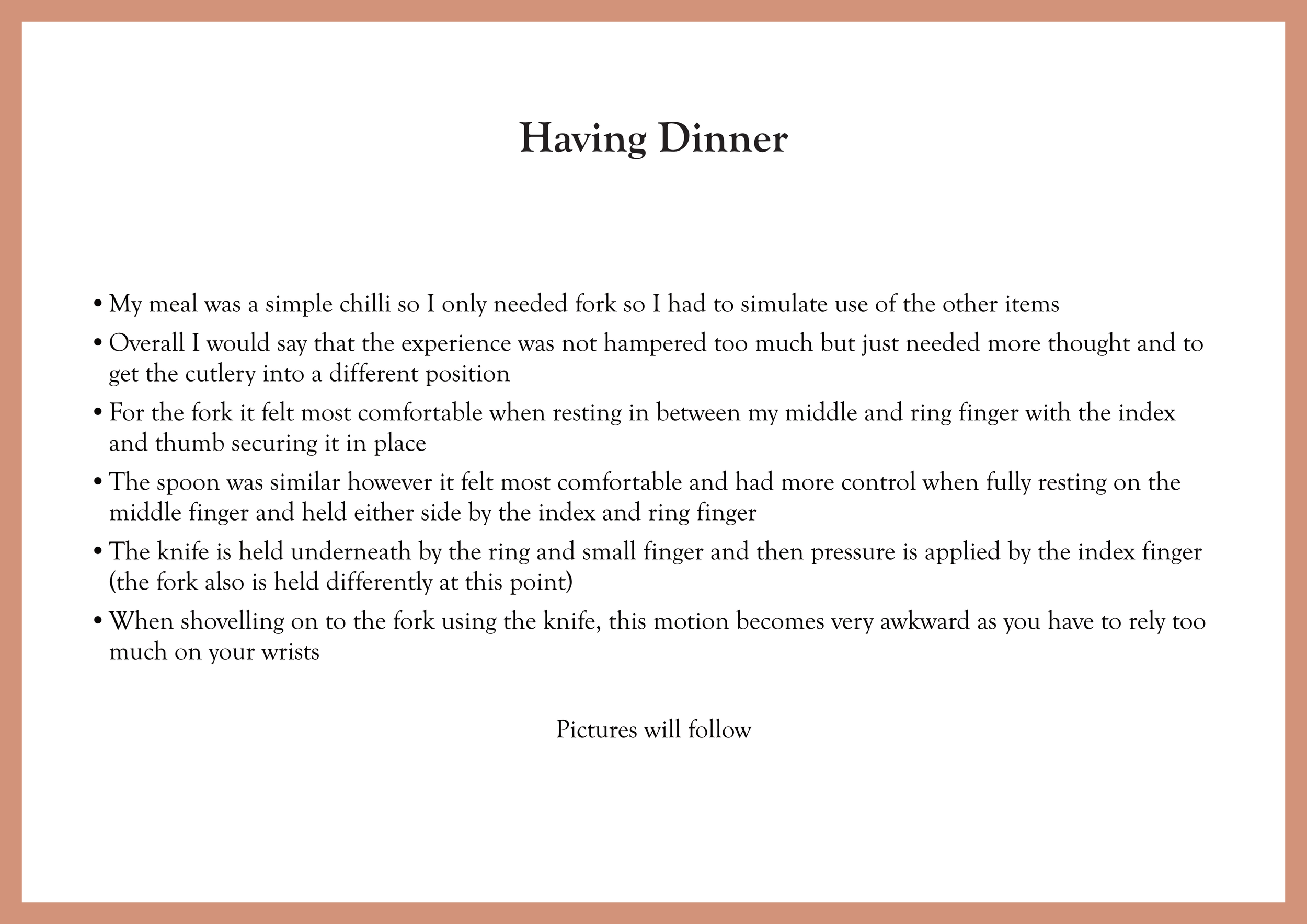

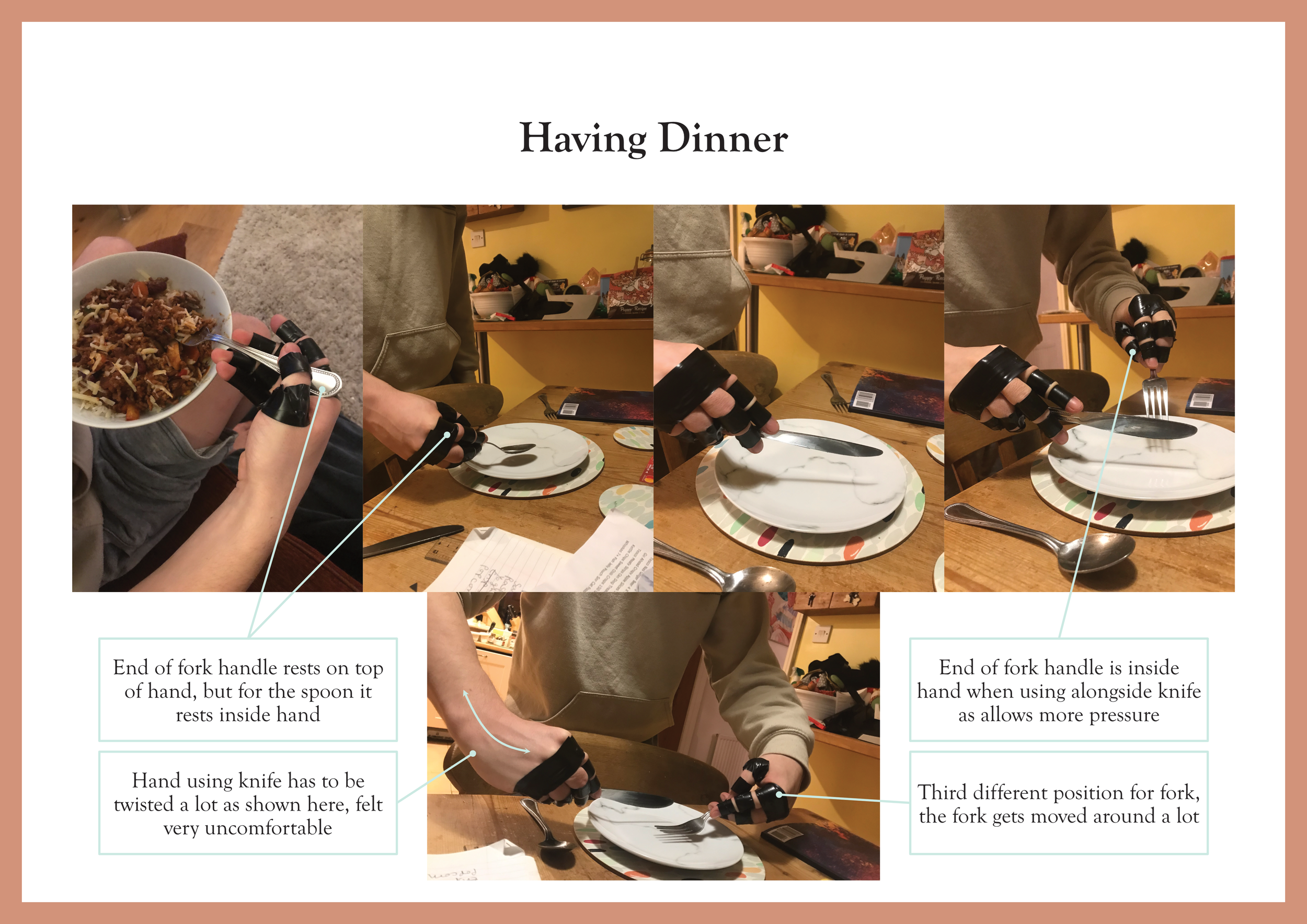

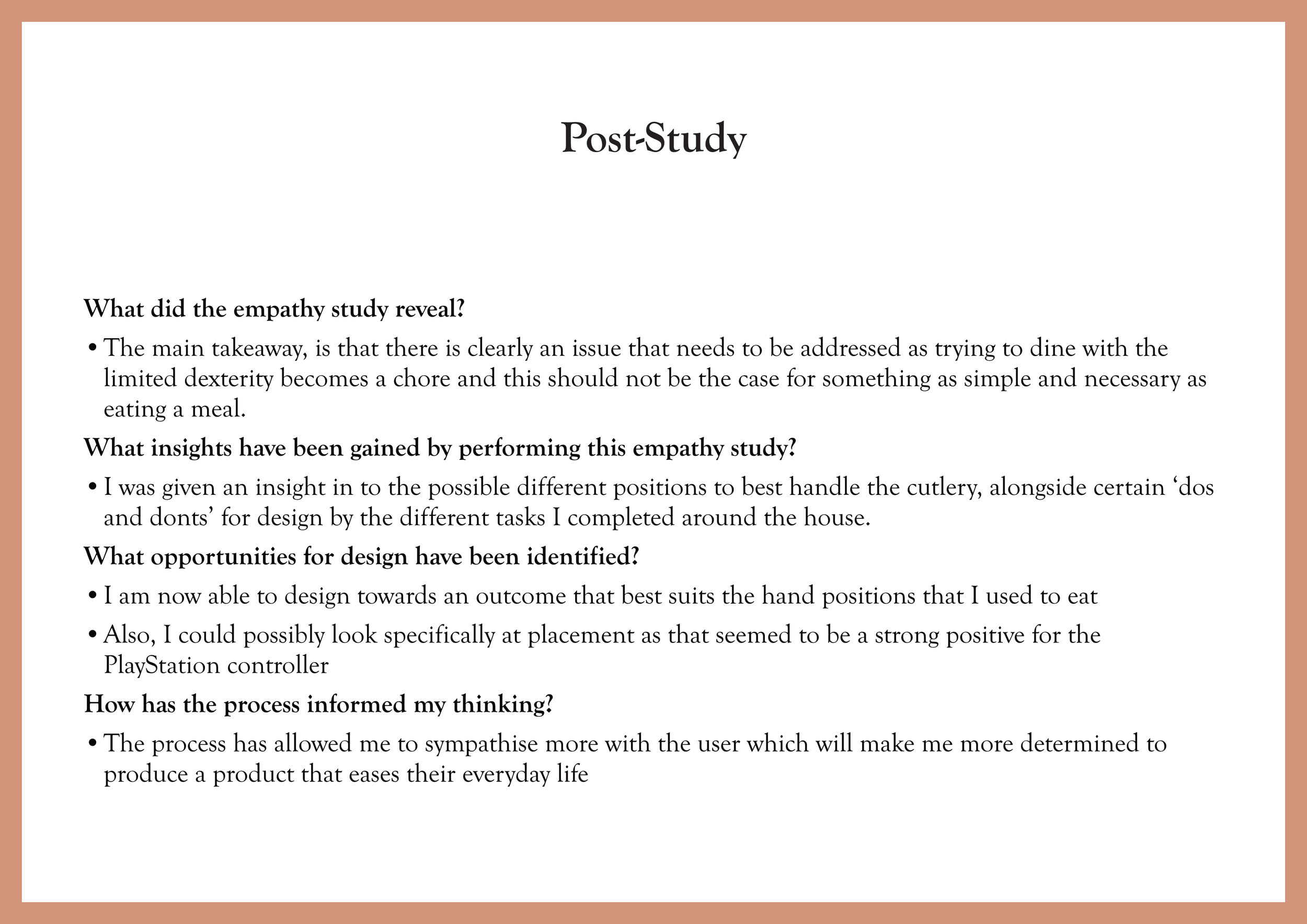

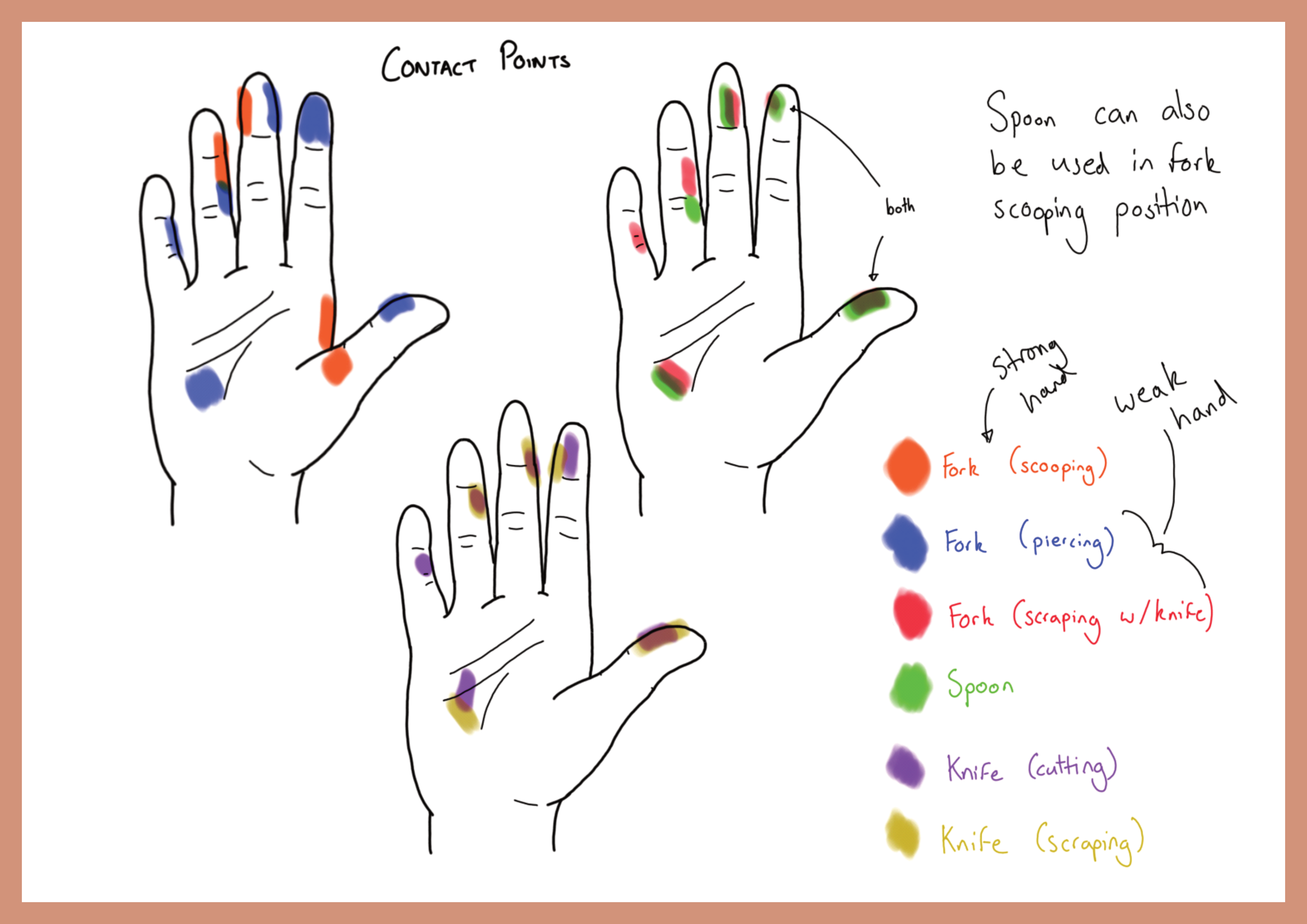

Empathy Study

Clay Modelling

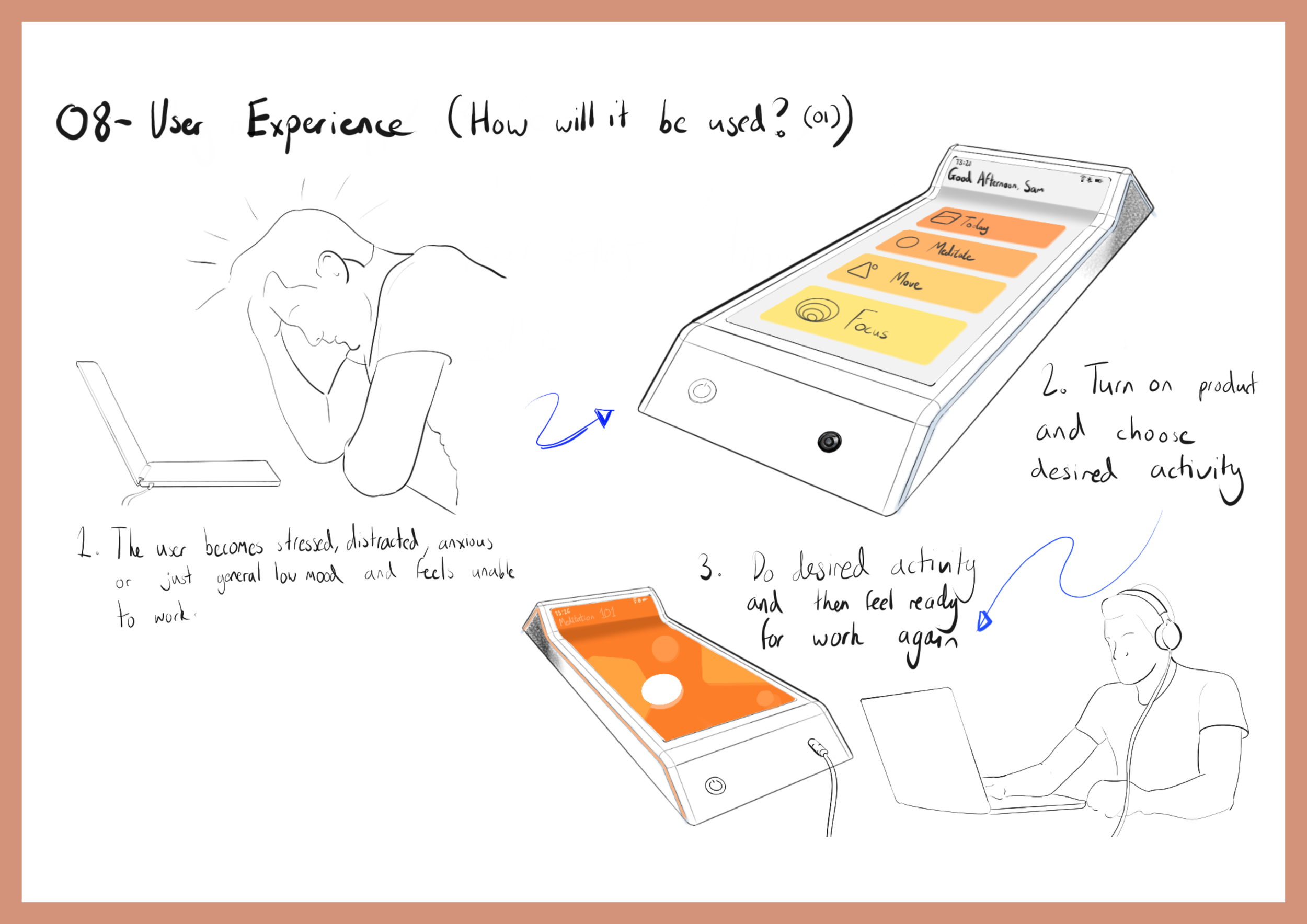

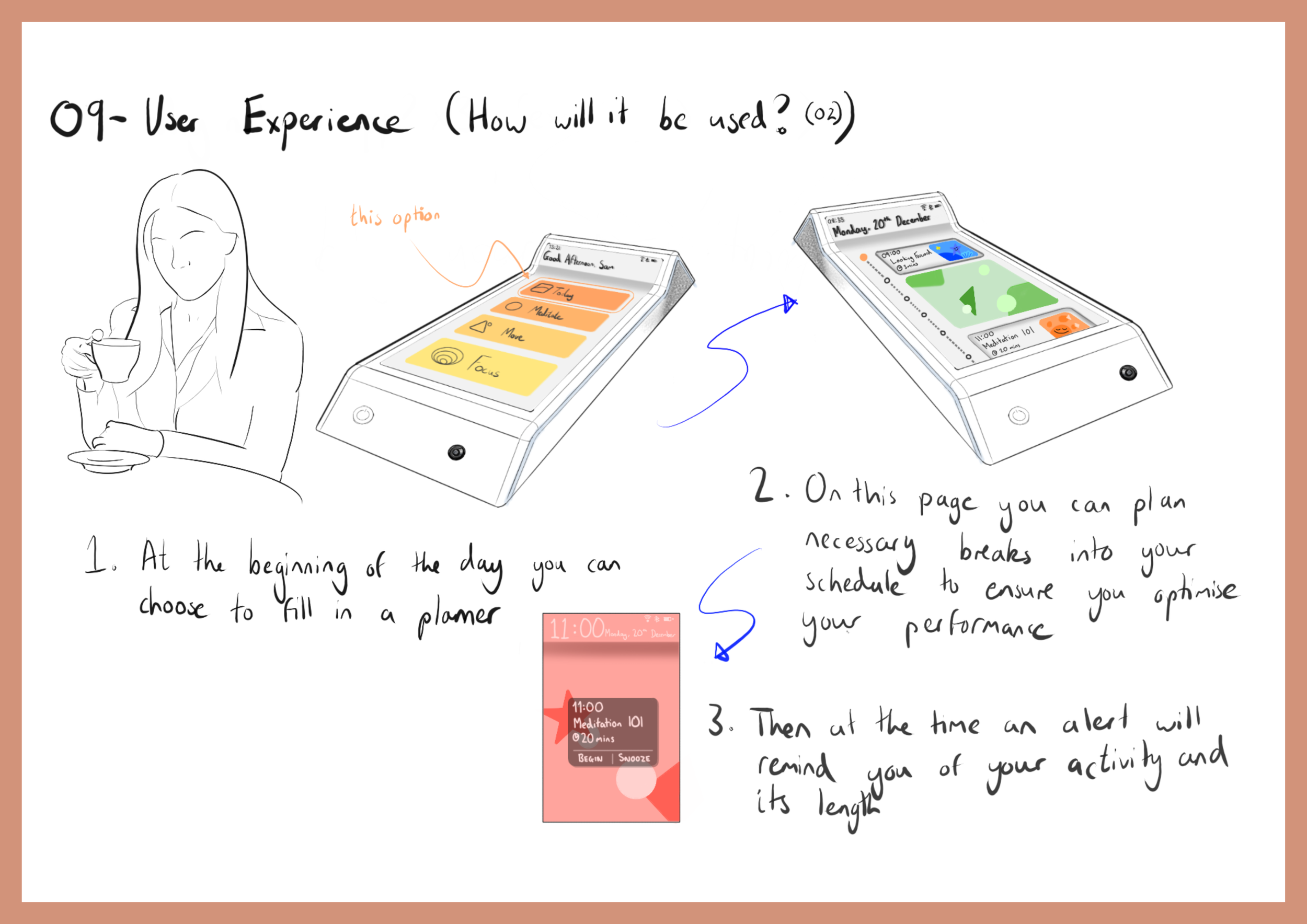

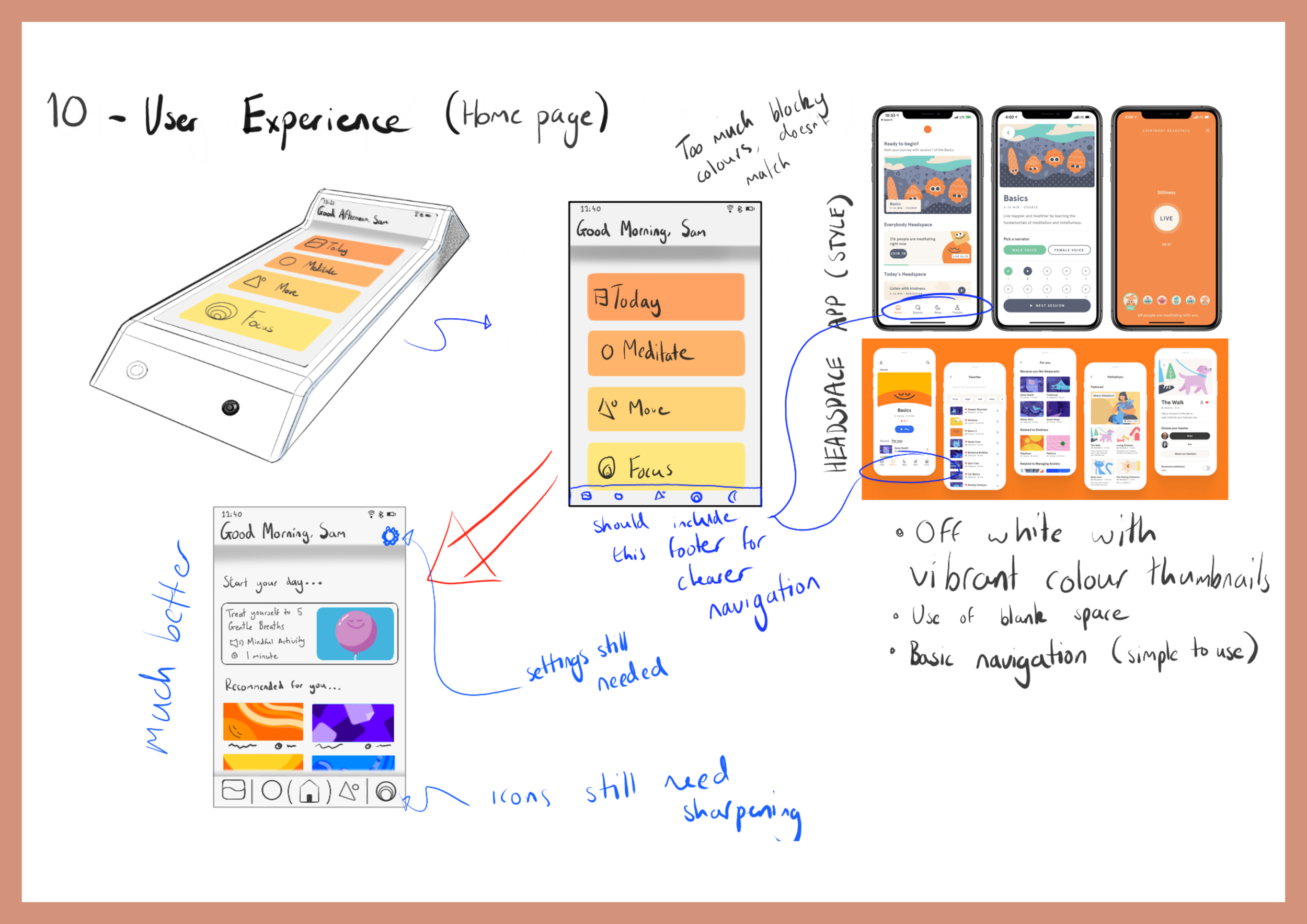

Mindful Home Office

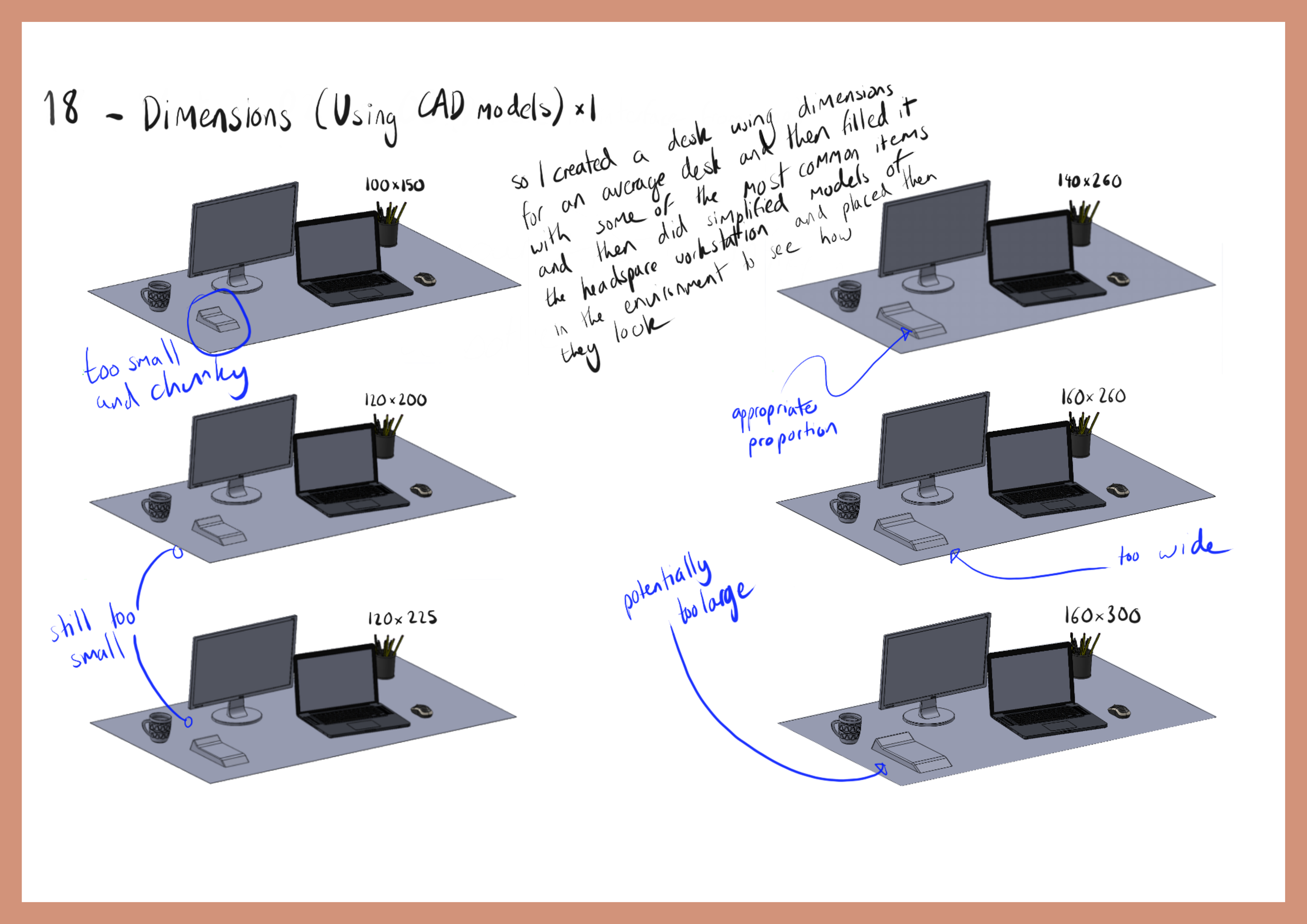

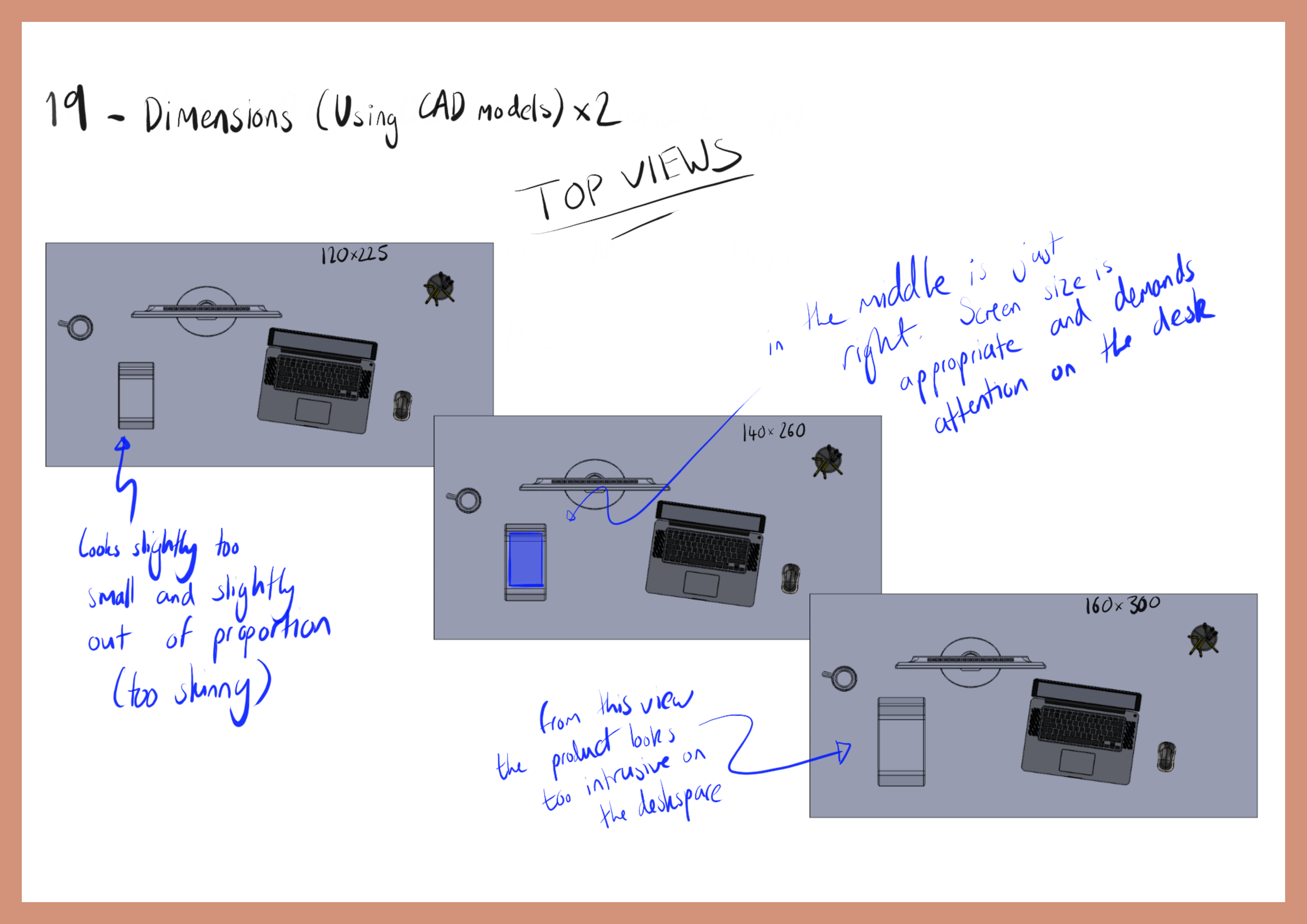

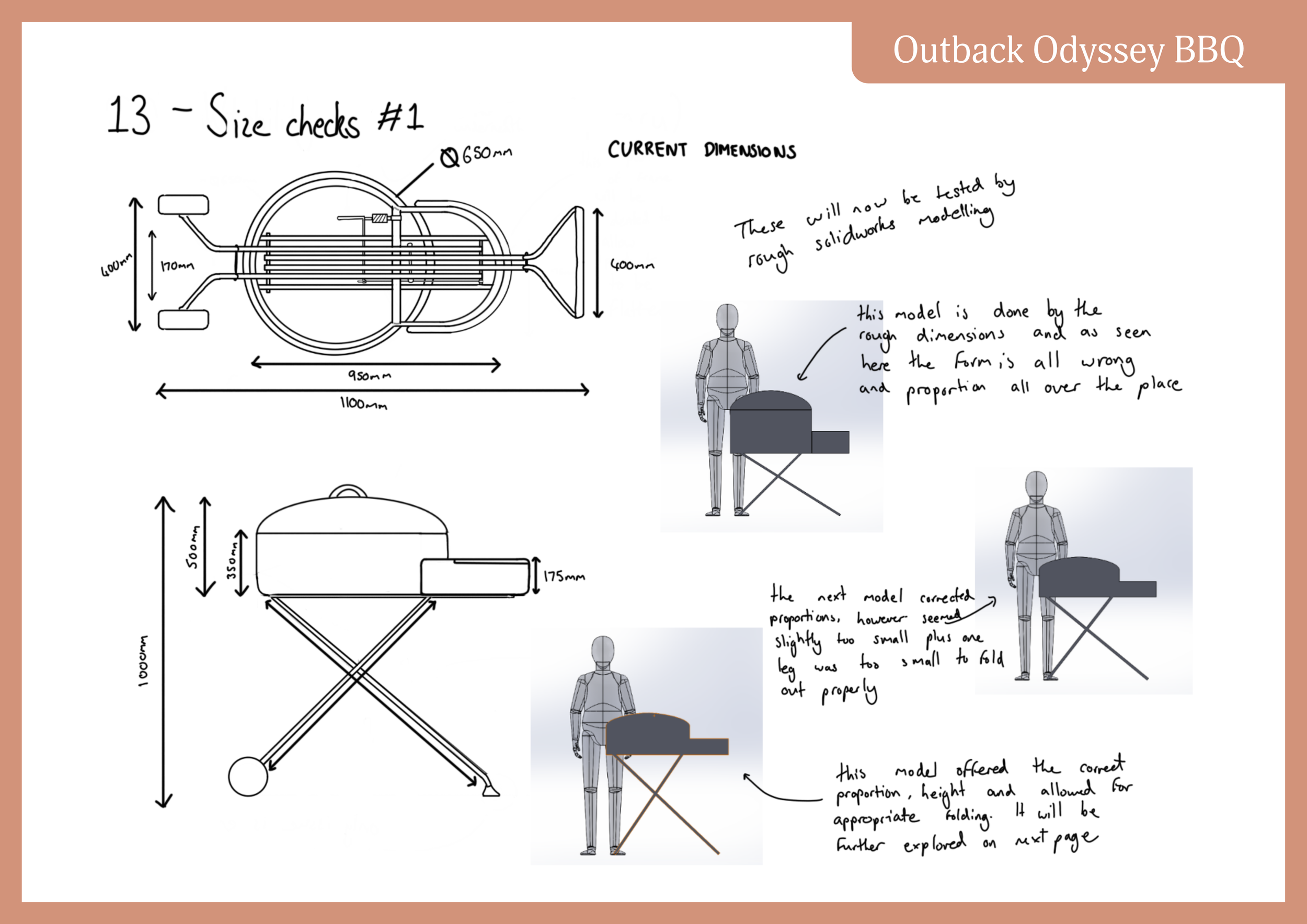

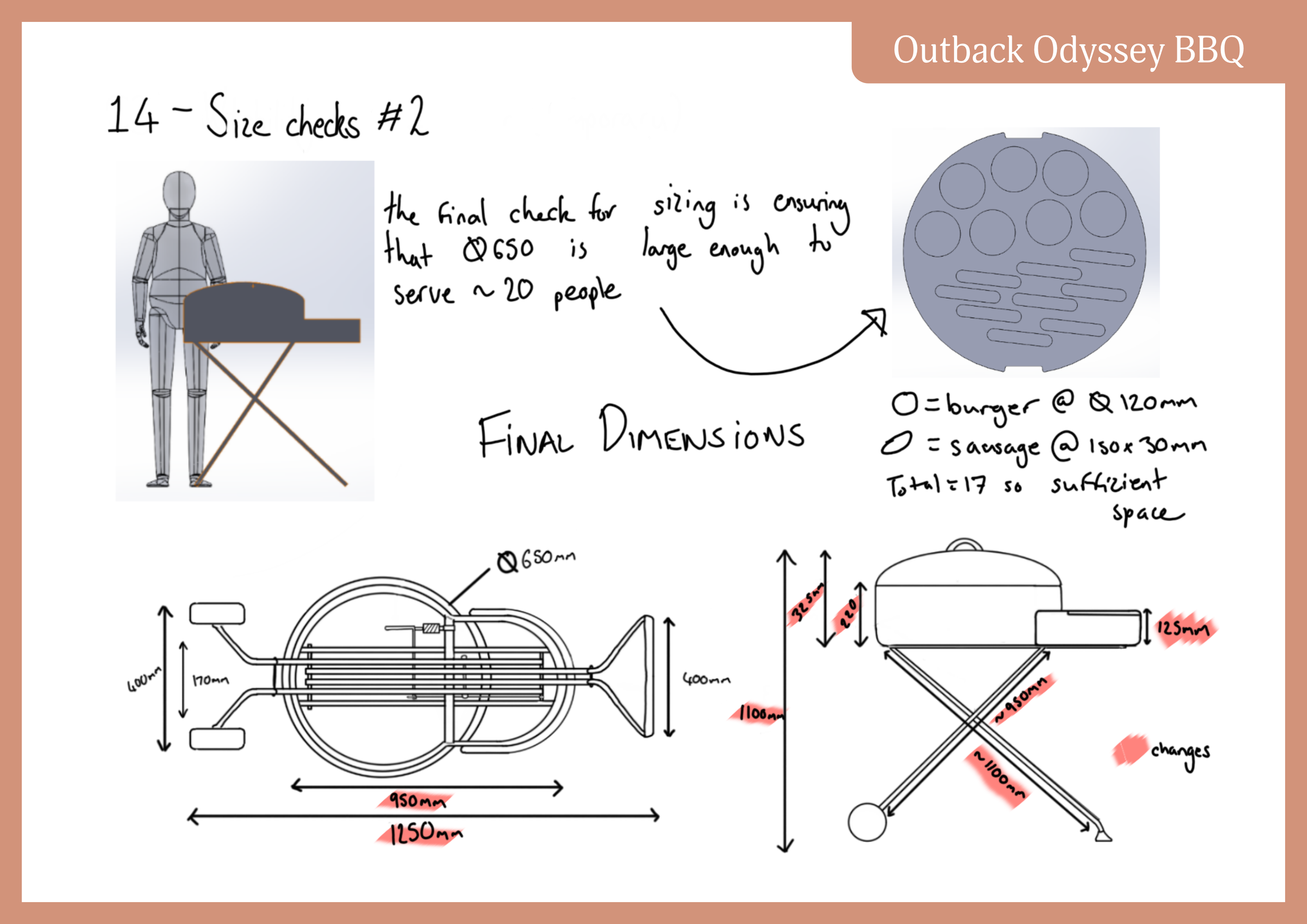

This project shows off the use of two more skills, those being a closer look towards the User Experience side of things (especially interfaces); as well as using CAD modelling to further enhance my development .

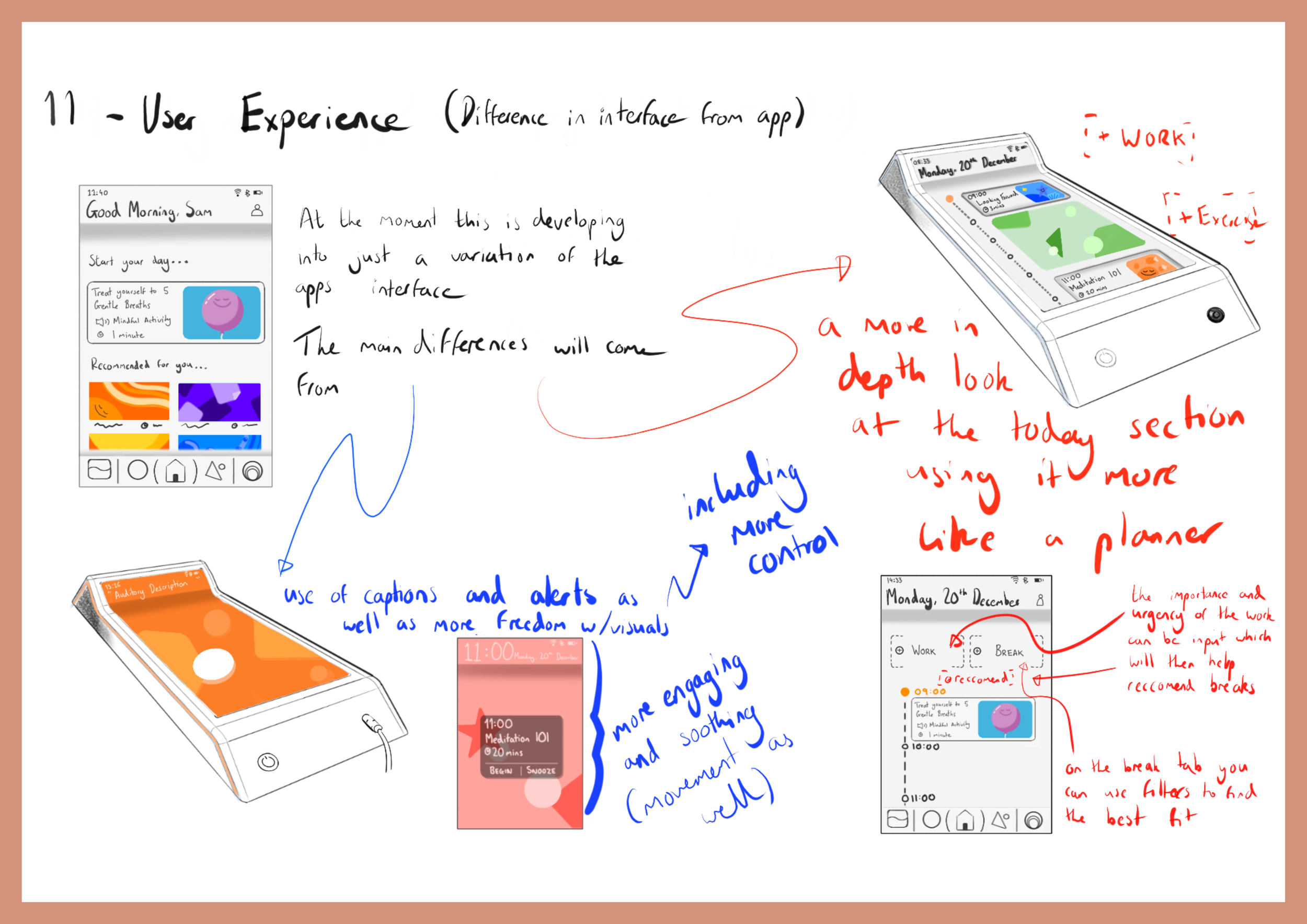

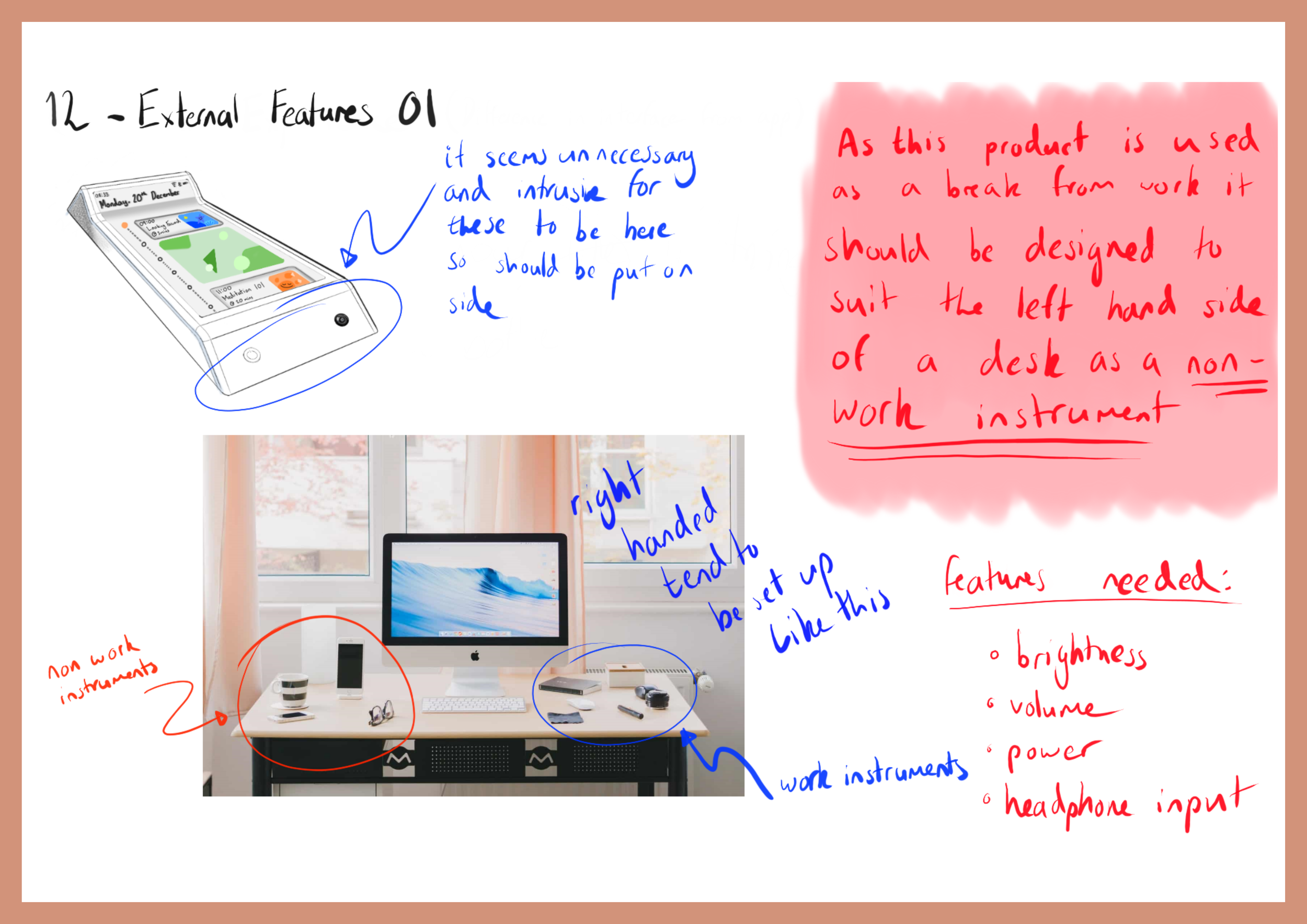

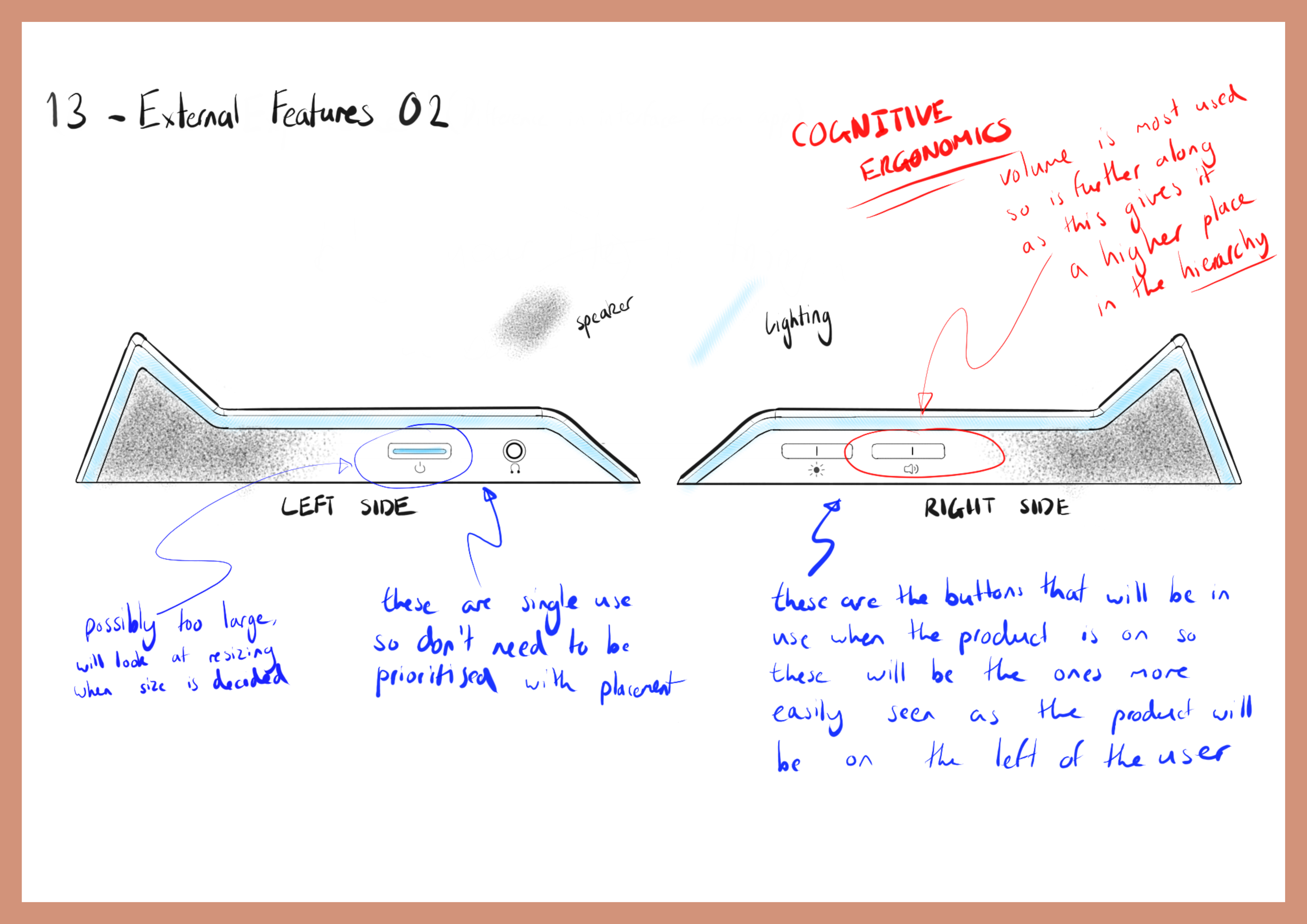

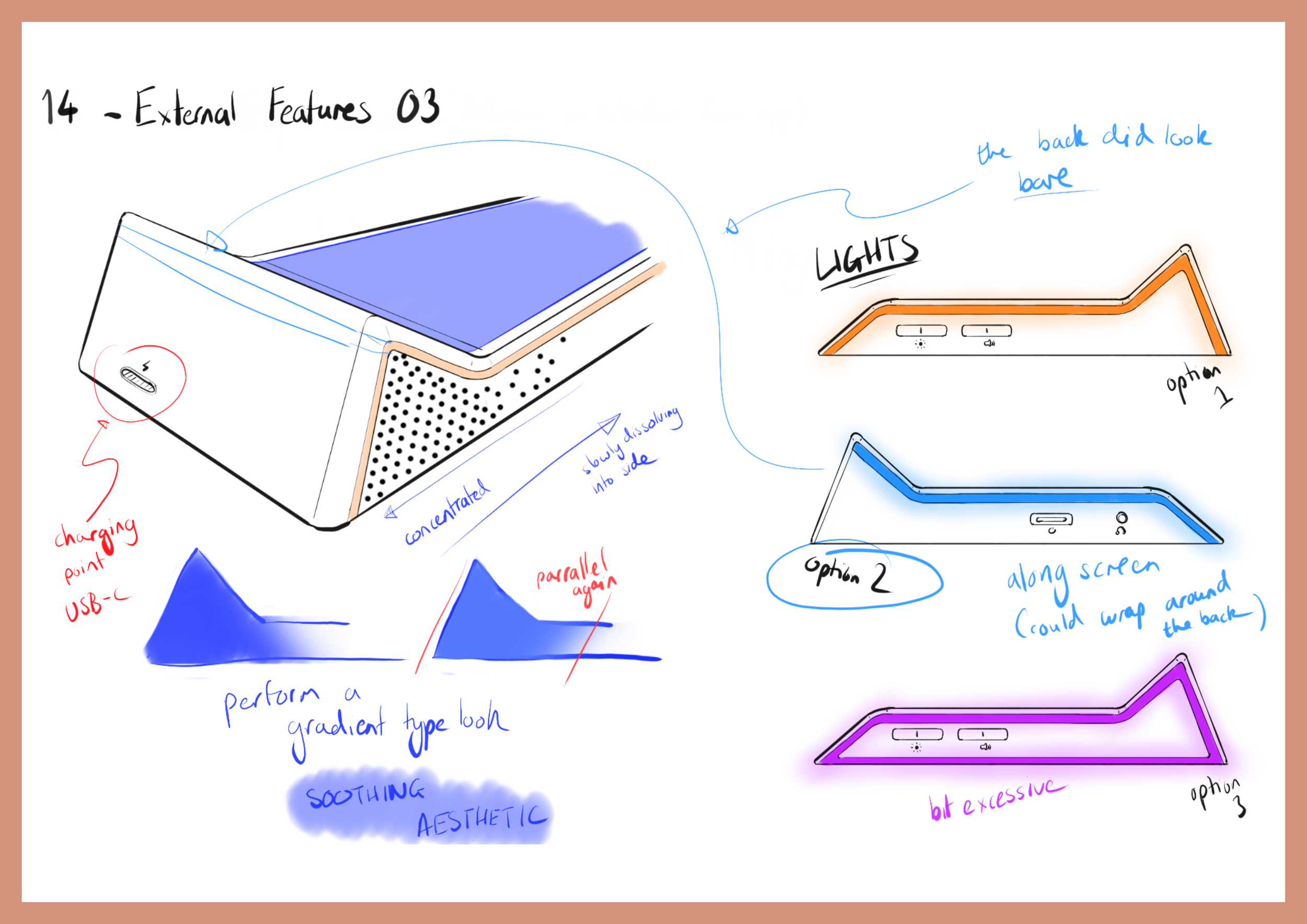

User Experience was important for this project in particular as it was my first time looking into interfaces meaning I put extra effort into the cognitive ergonomic side of things as well as the physical ergonomic side. The CAD modelling was a very effective use of development time as it allowed a very quick look at how my product would look amongst a larger scene, which would have been much harder to recreate in physical form. I also used this approach for my BBQ project which I will also show off here…

User Experience

CAD modelling

As this was my major project it is also a place where I show off some of my best development skills, these include:

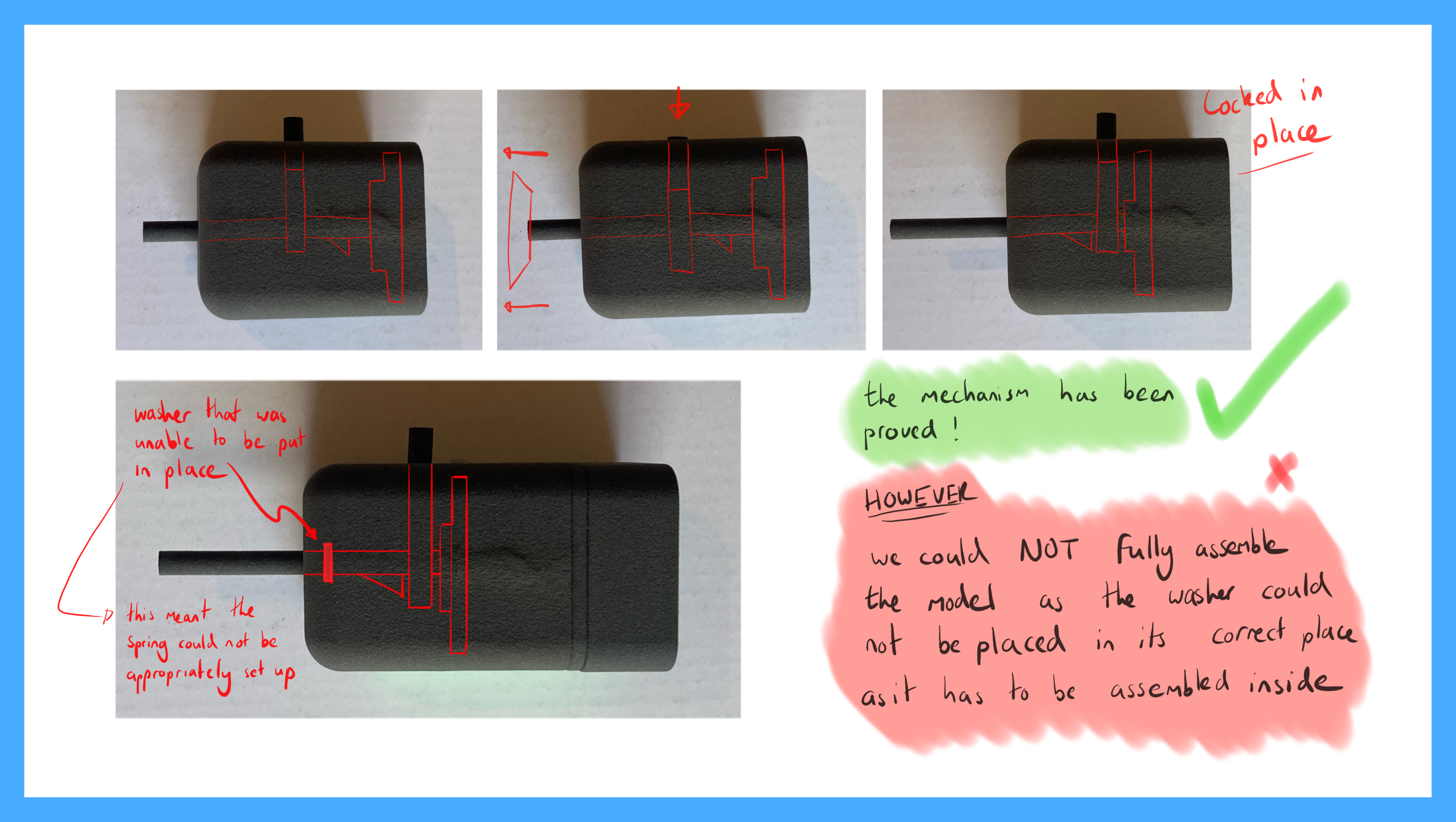

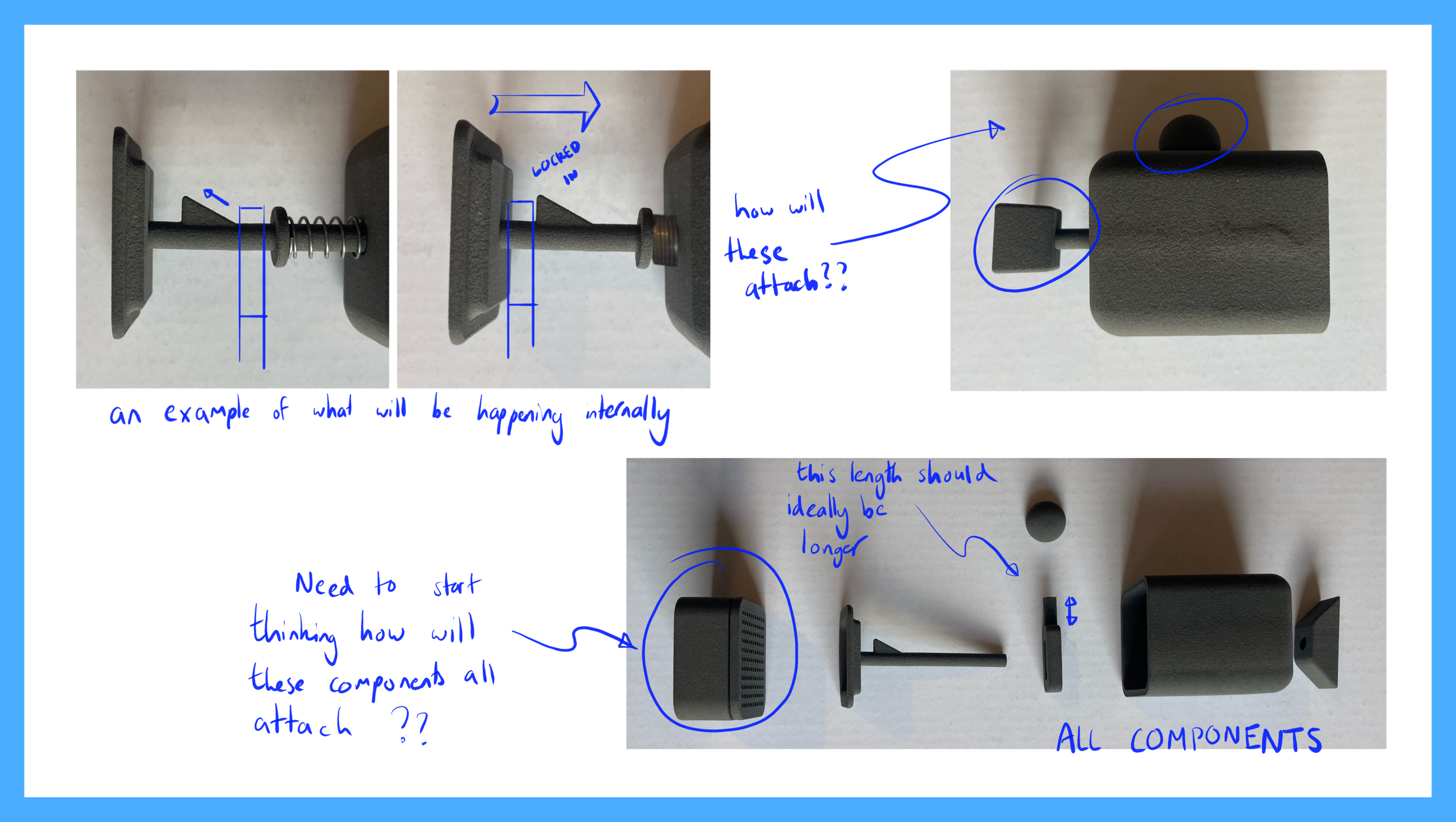

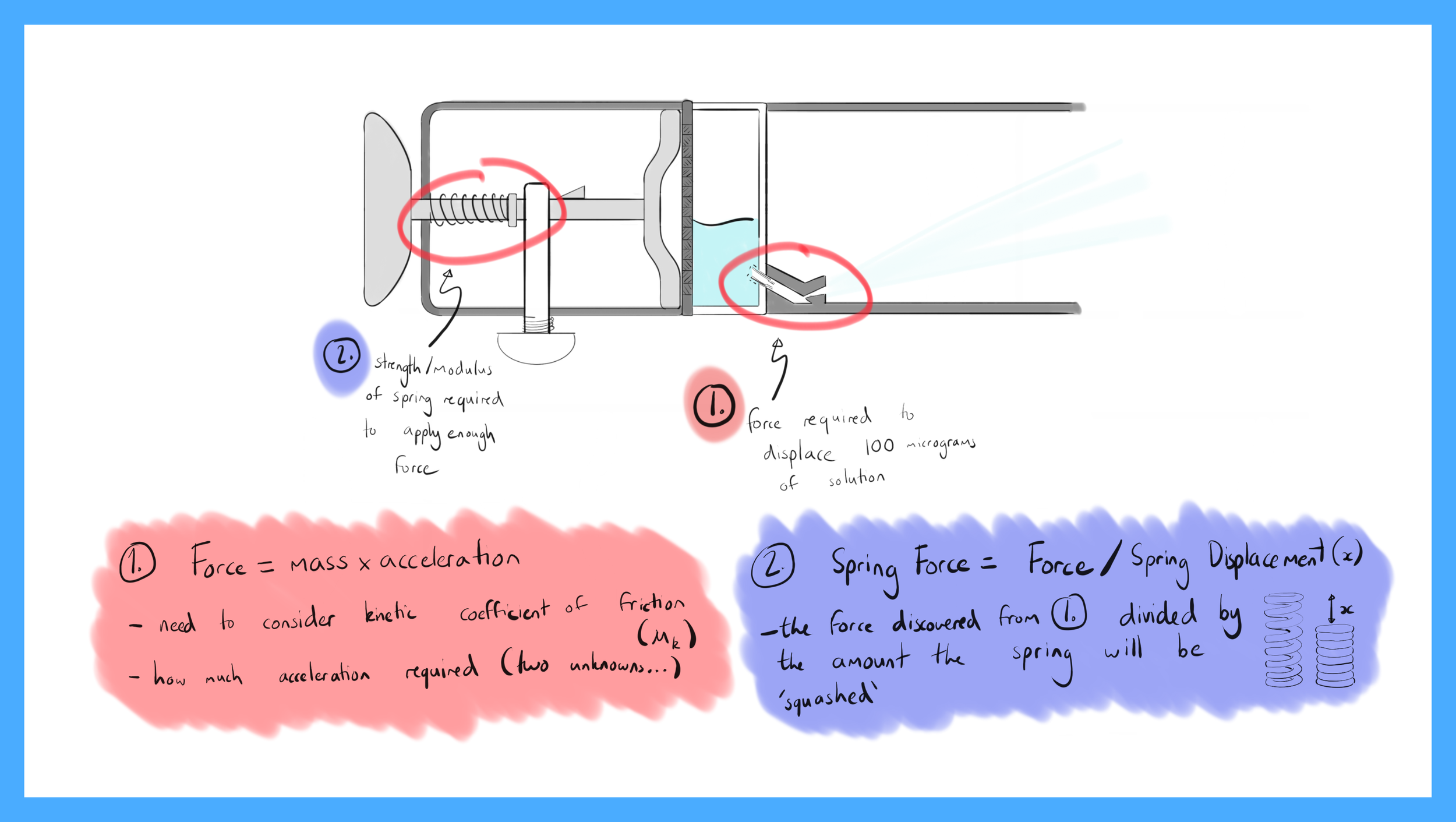

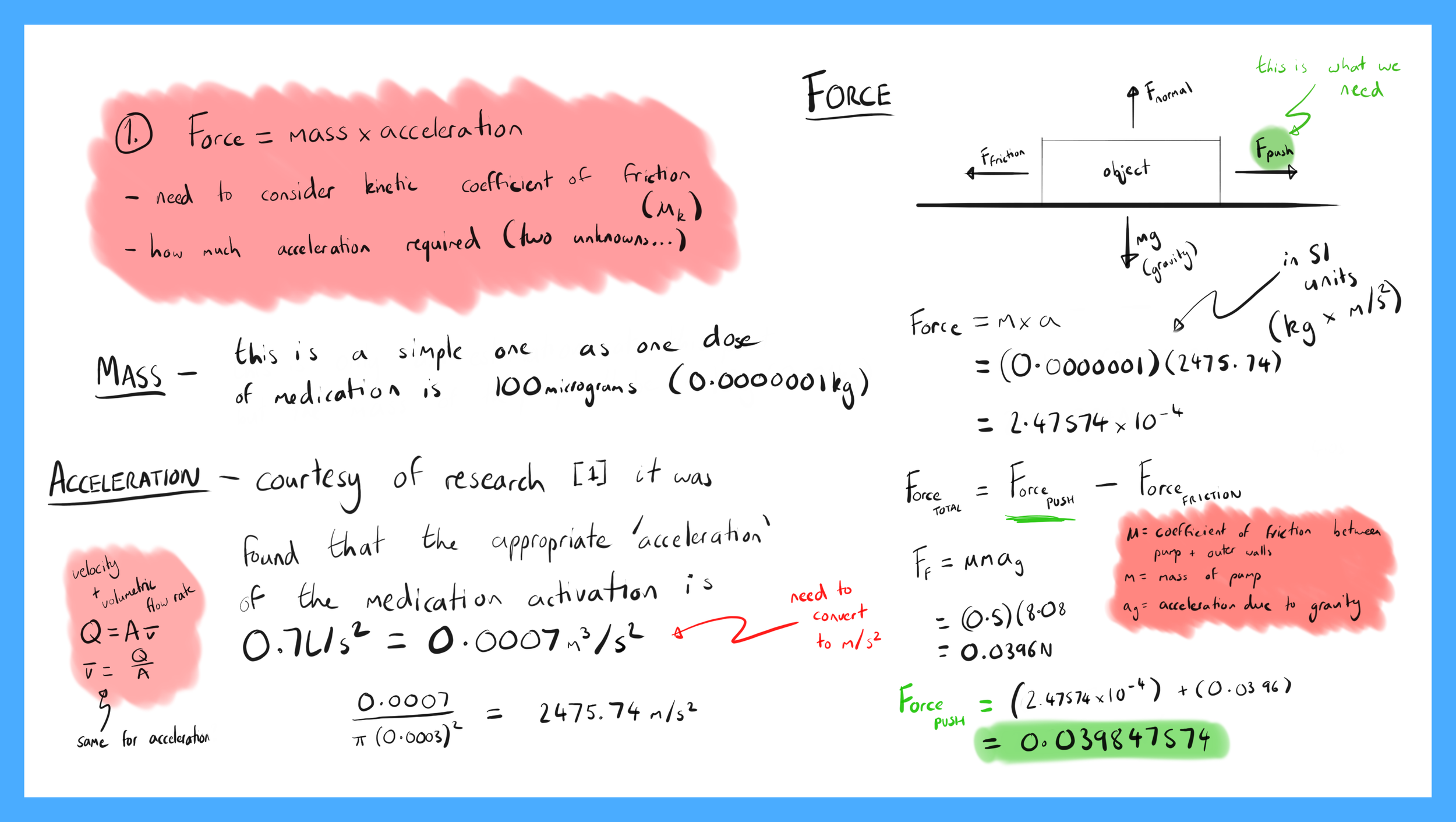

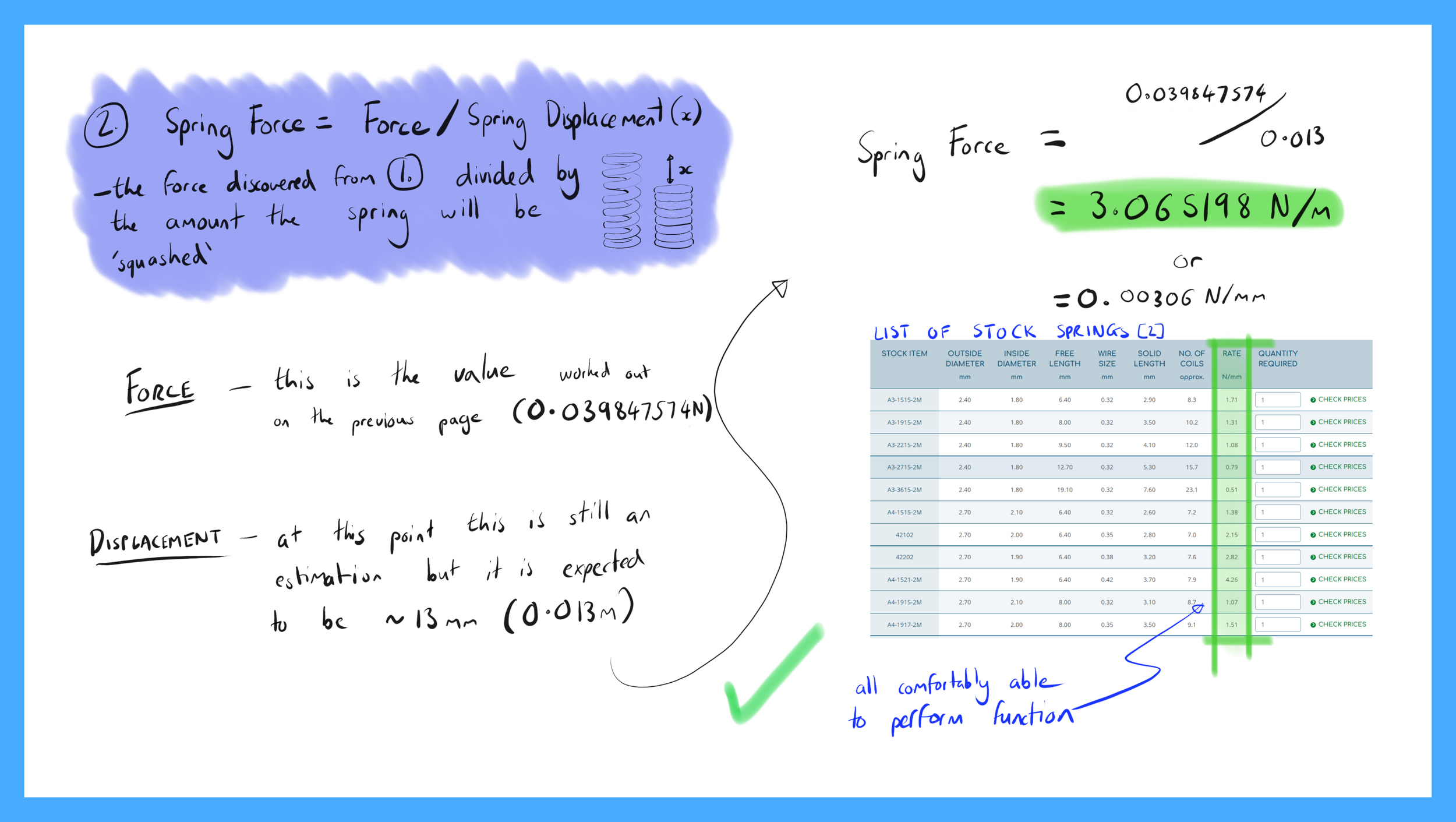

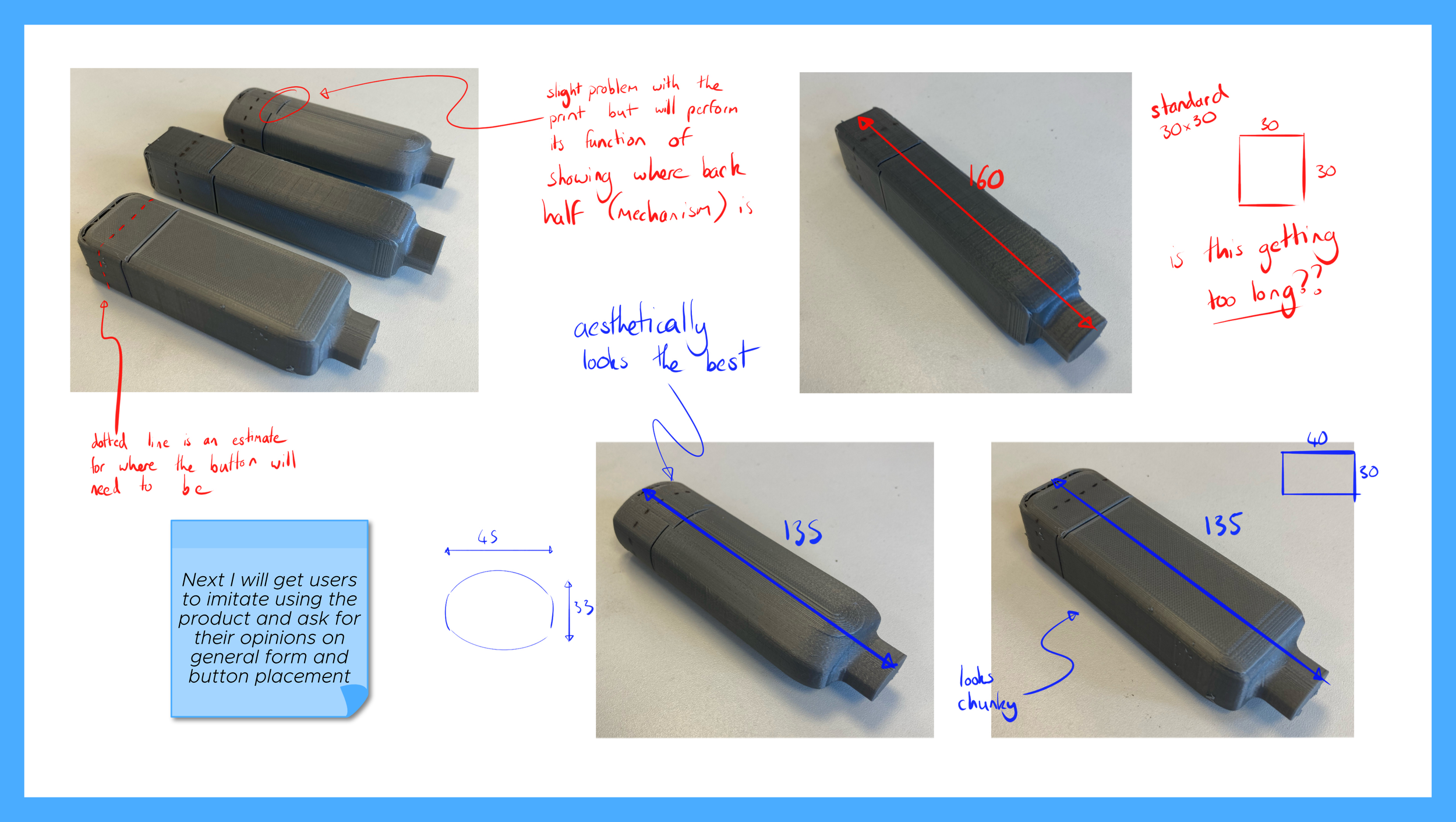

My mechanism development through the use of SLA 3D printed models, as well as maths/physics to prove my mechanism is feasible.

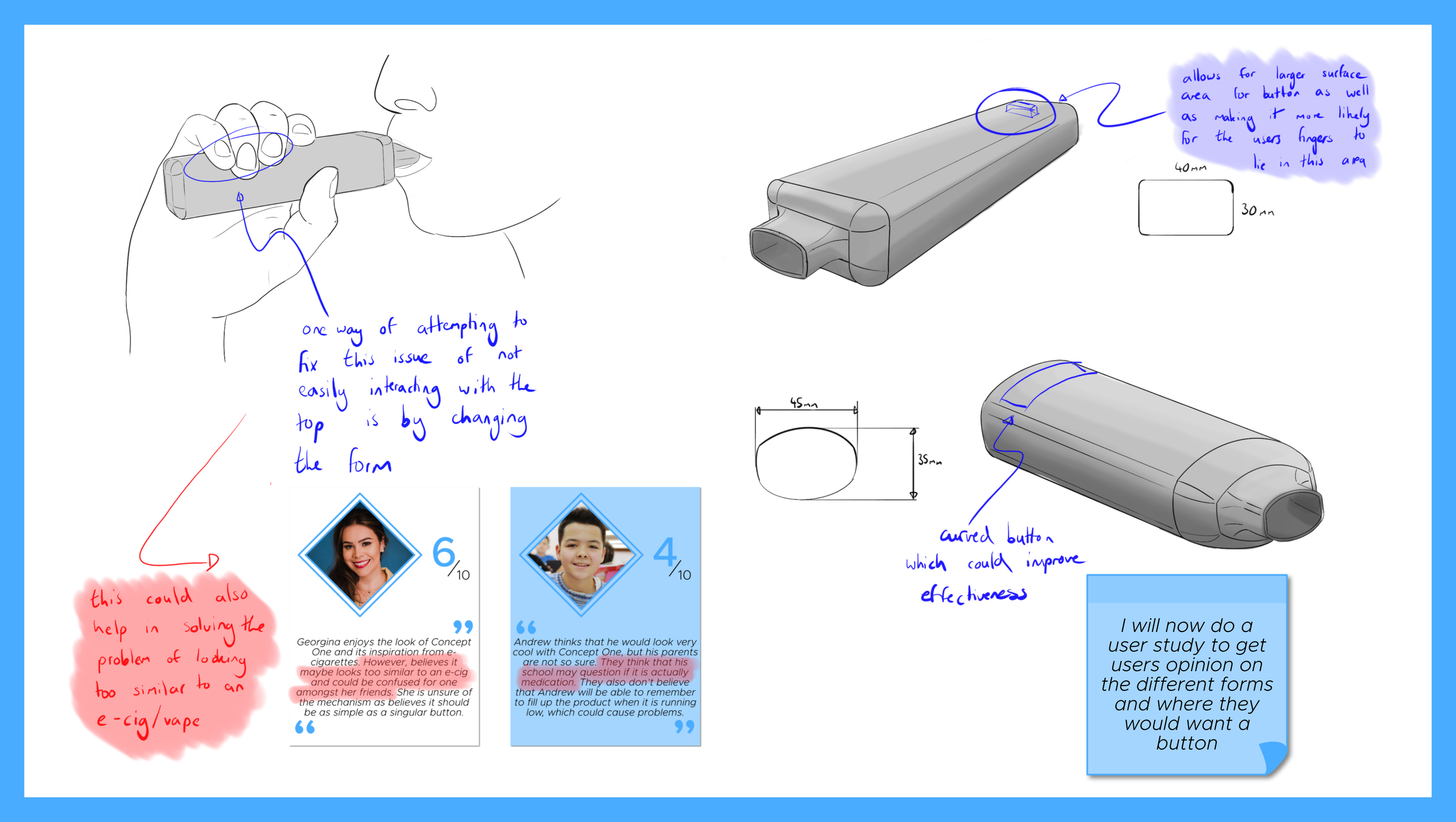

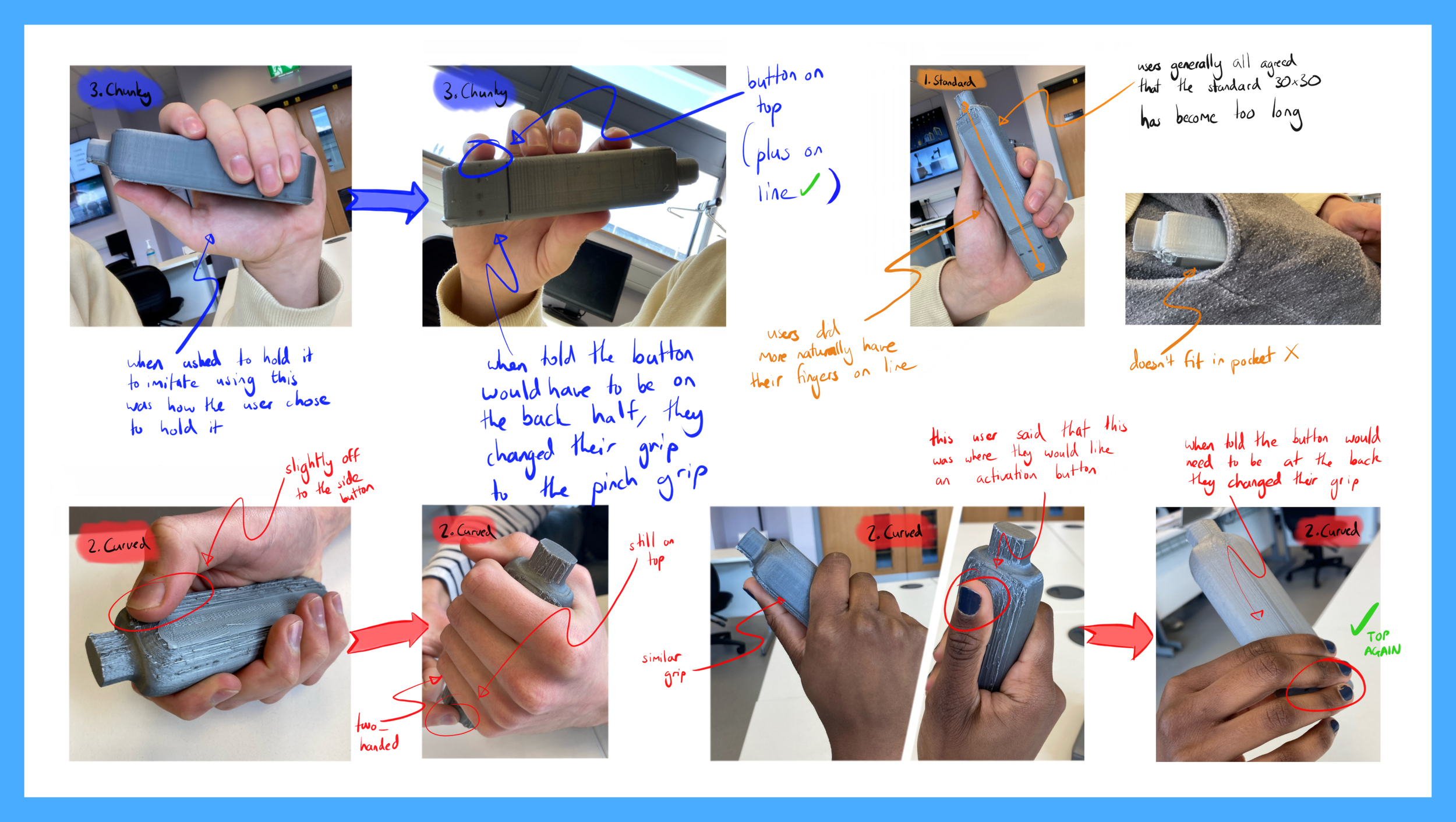

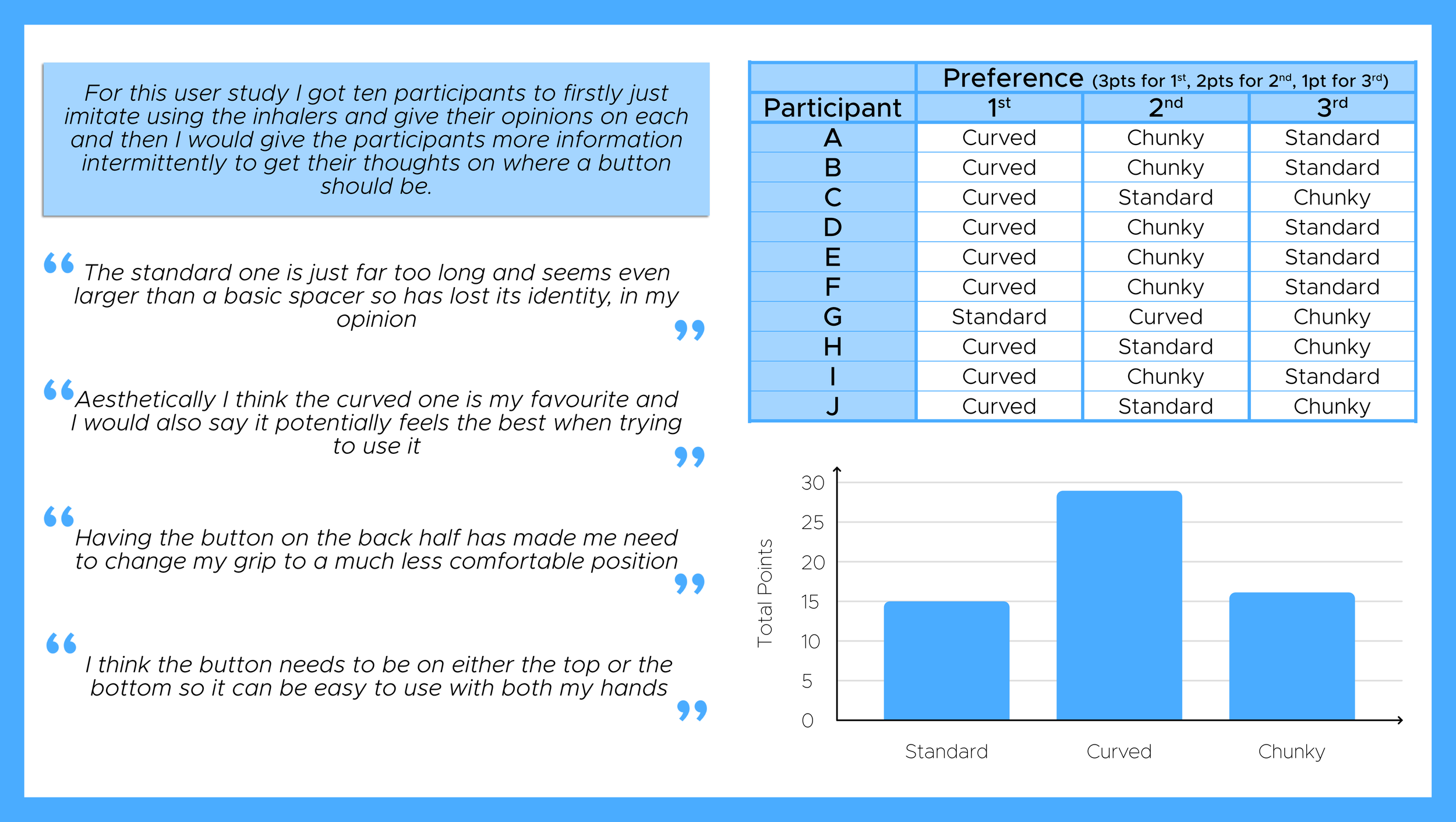

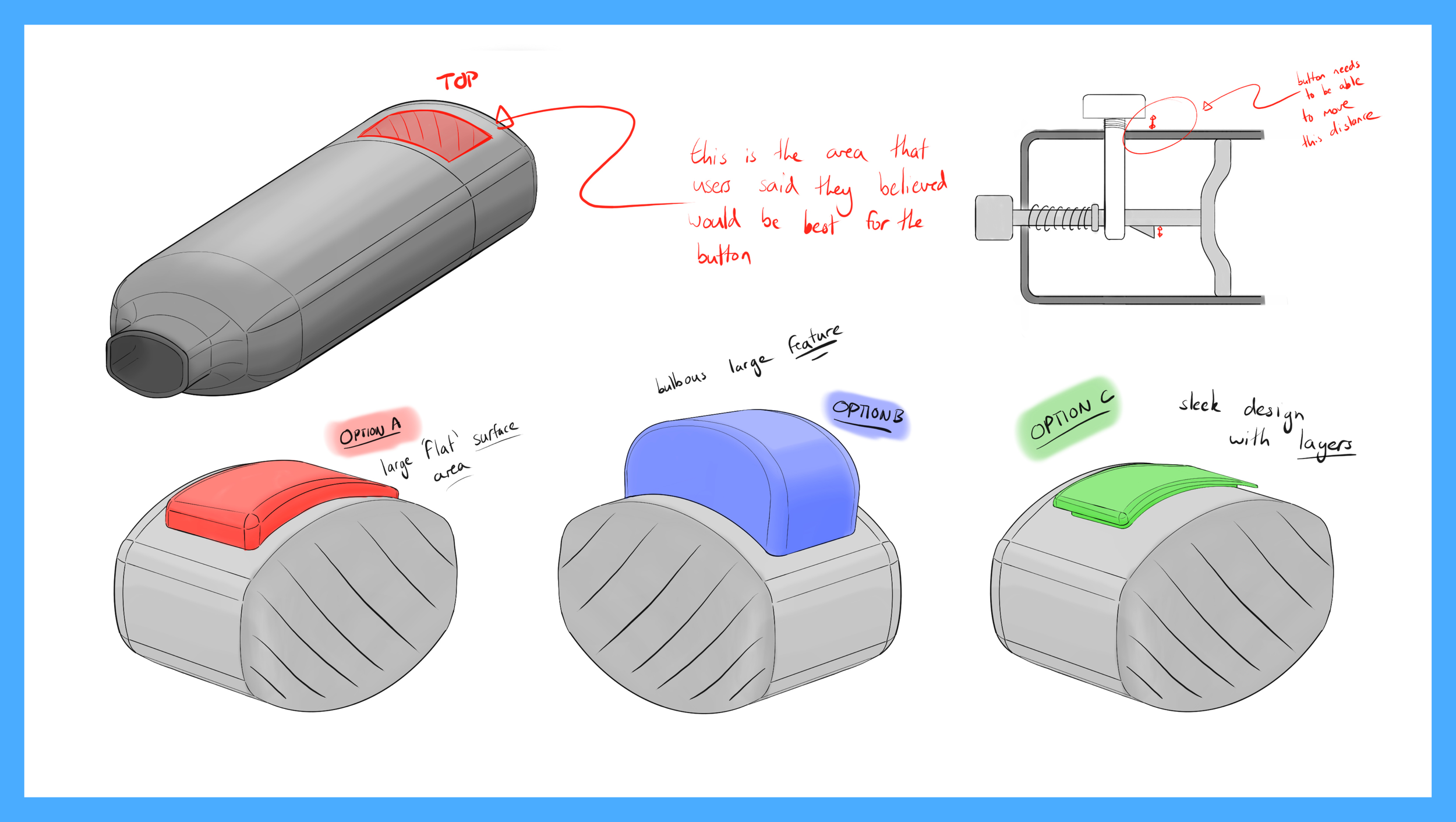

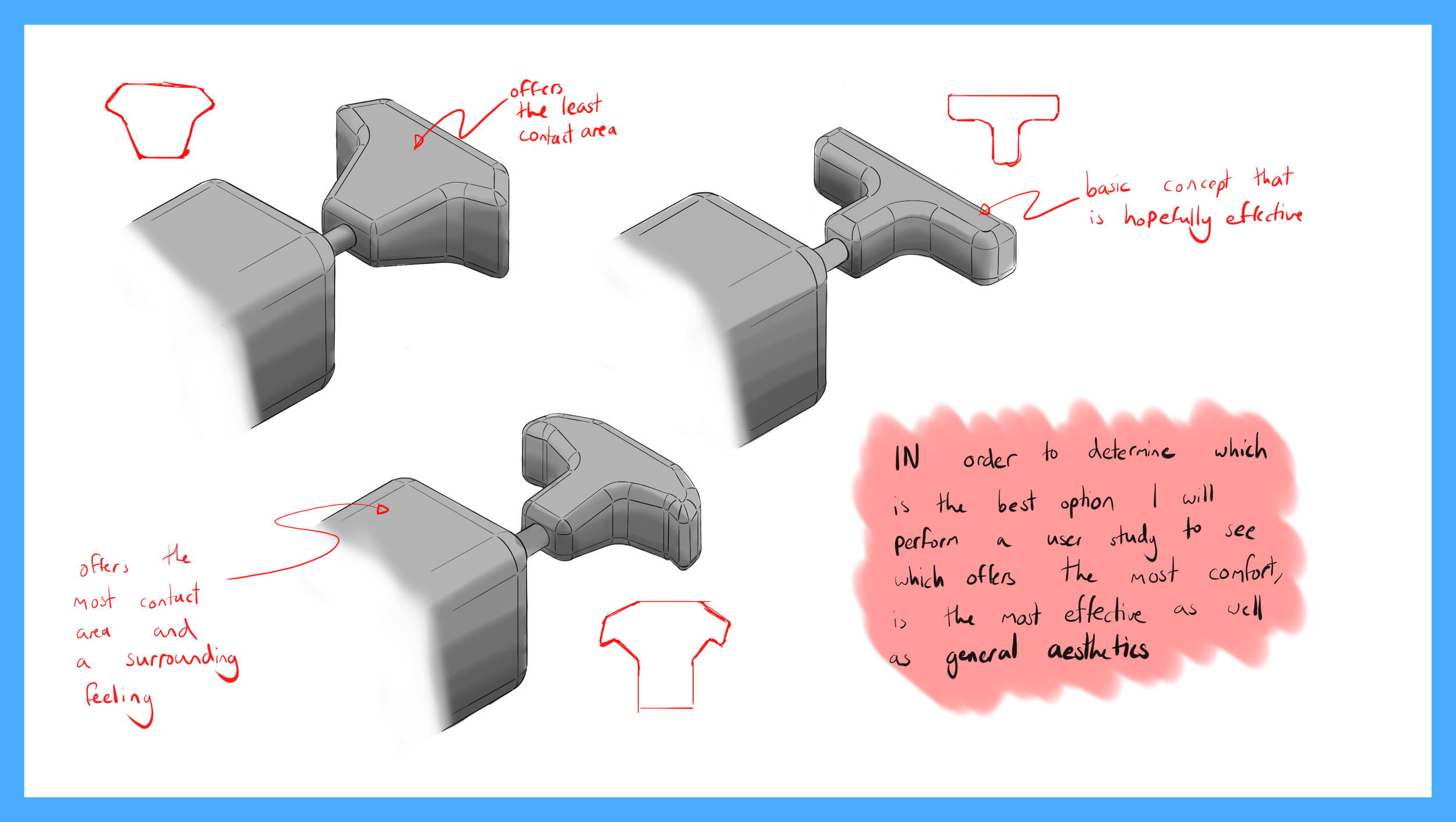

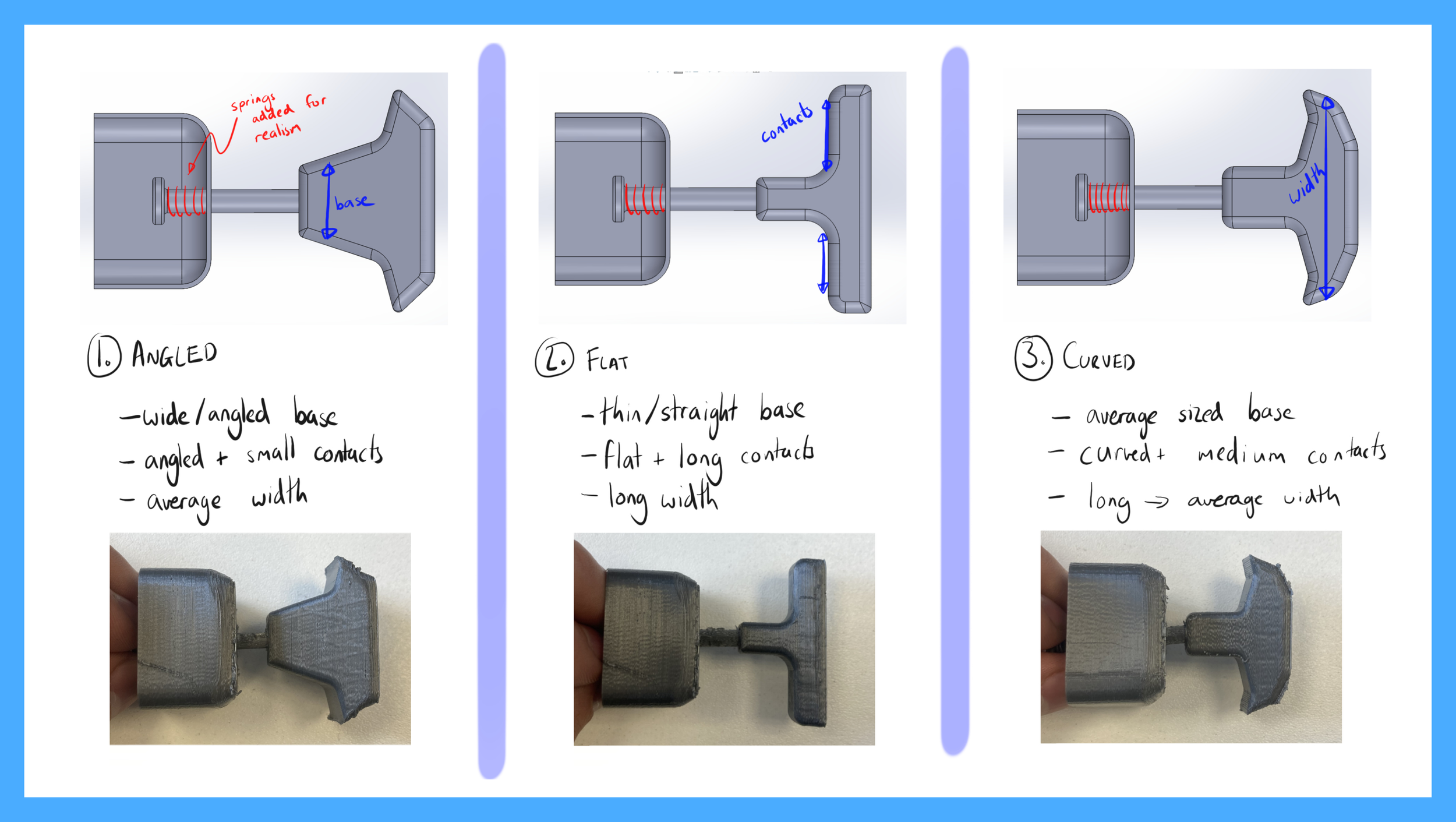

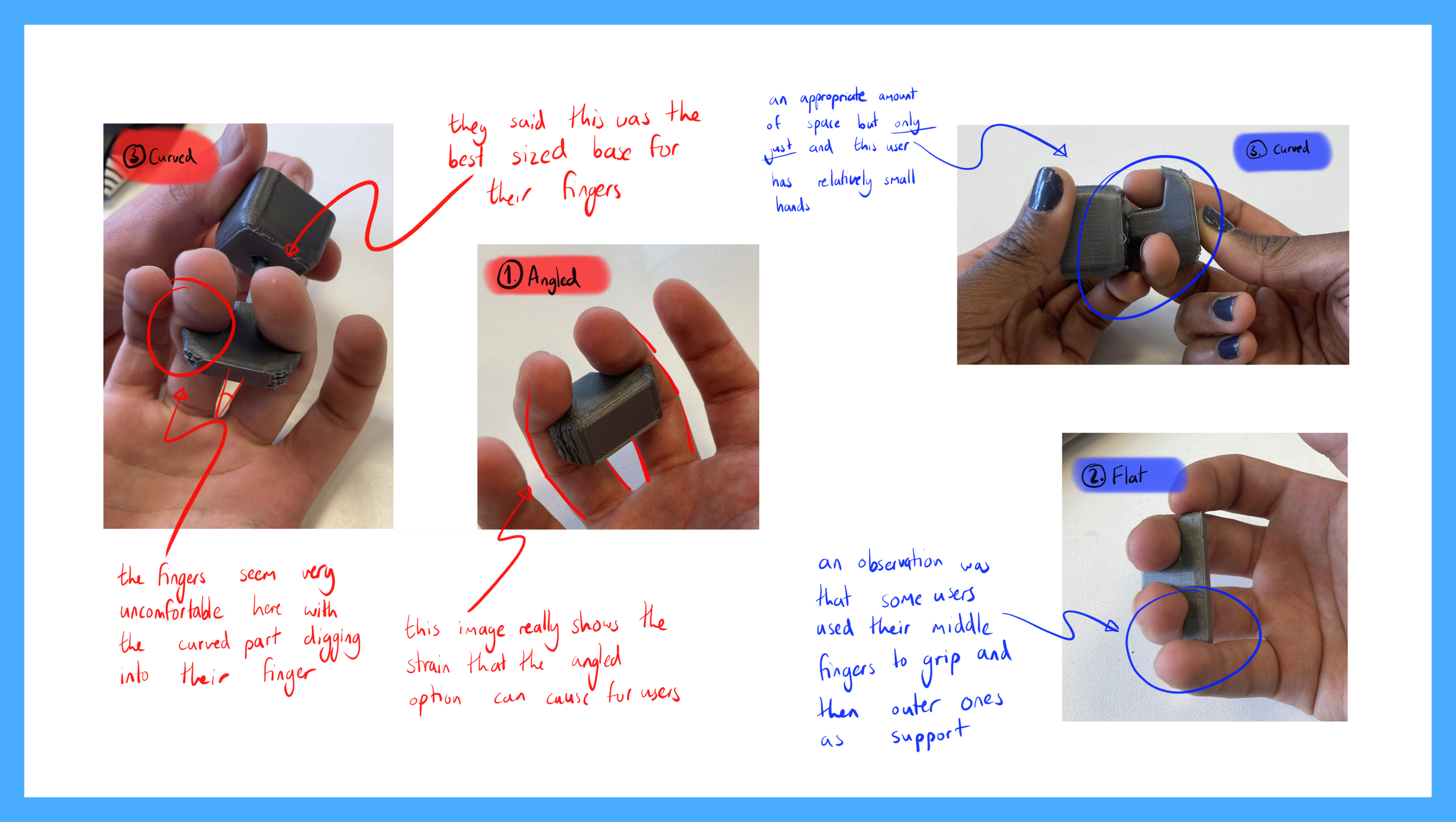

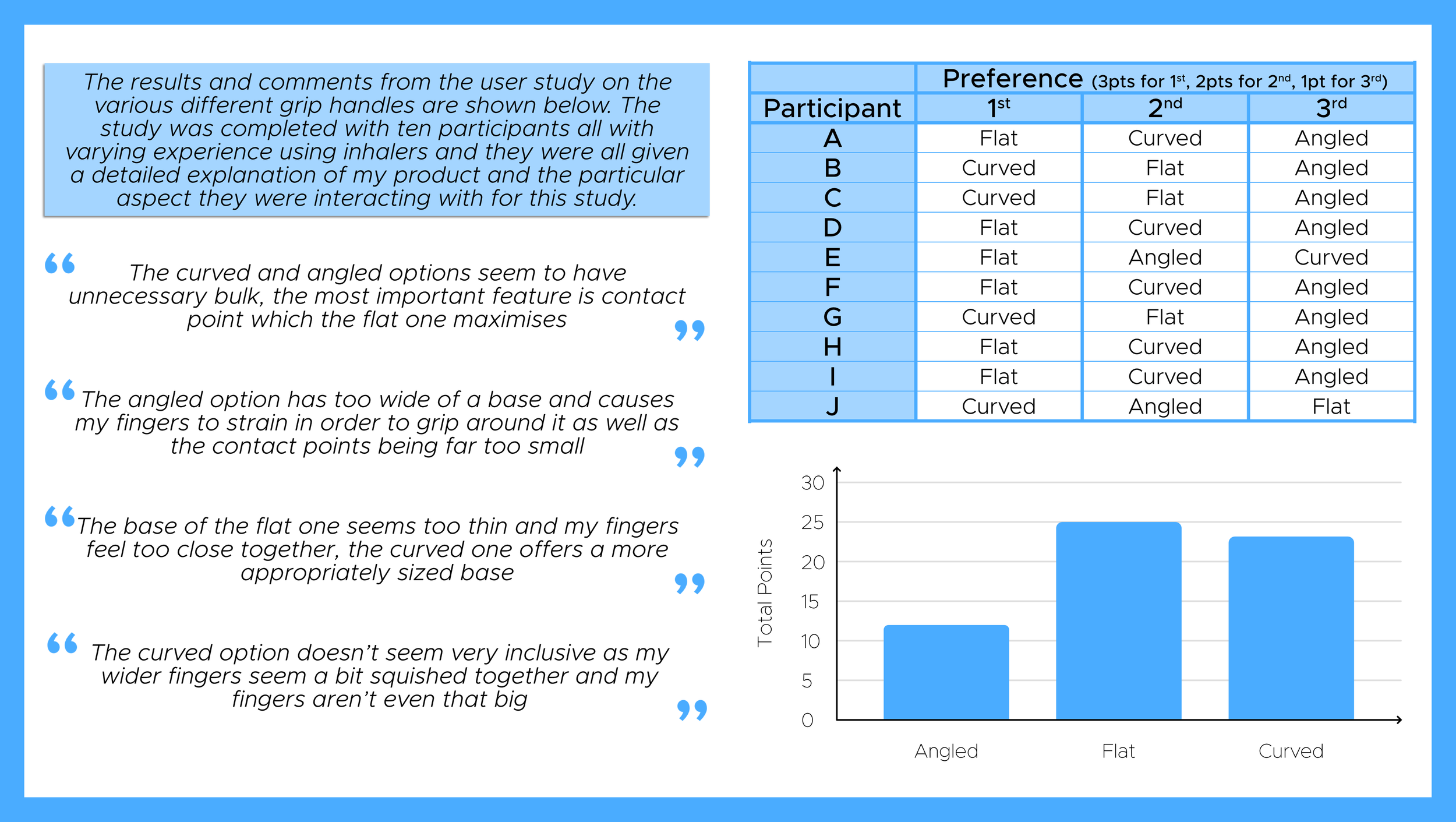

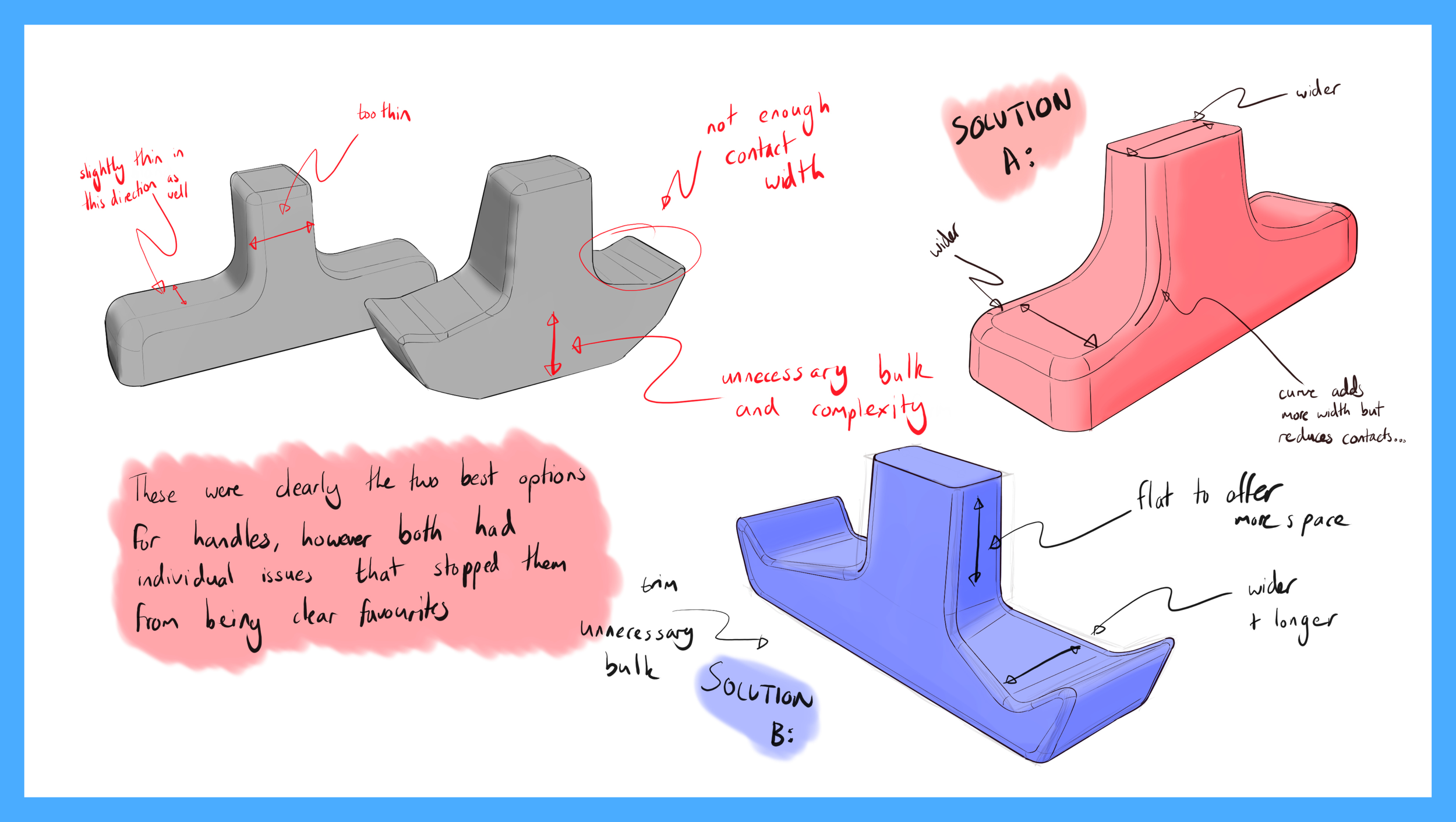

My user studies that were done with several FDM 3D printed models to ensure I am optimising human factors and ergonomics when it comes to the forms of my product.

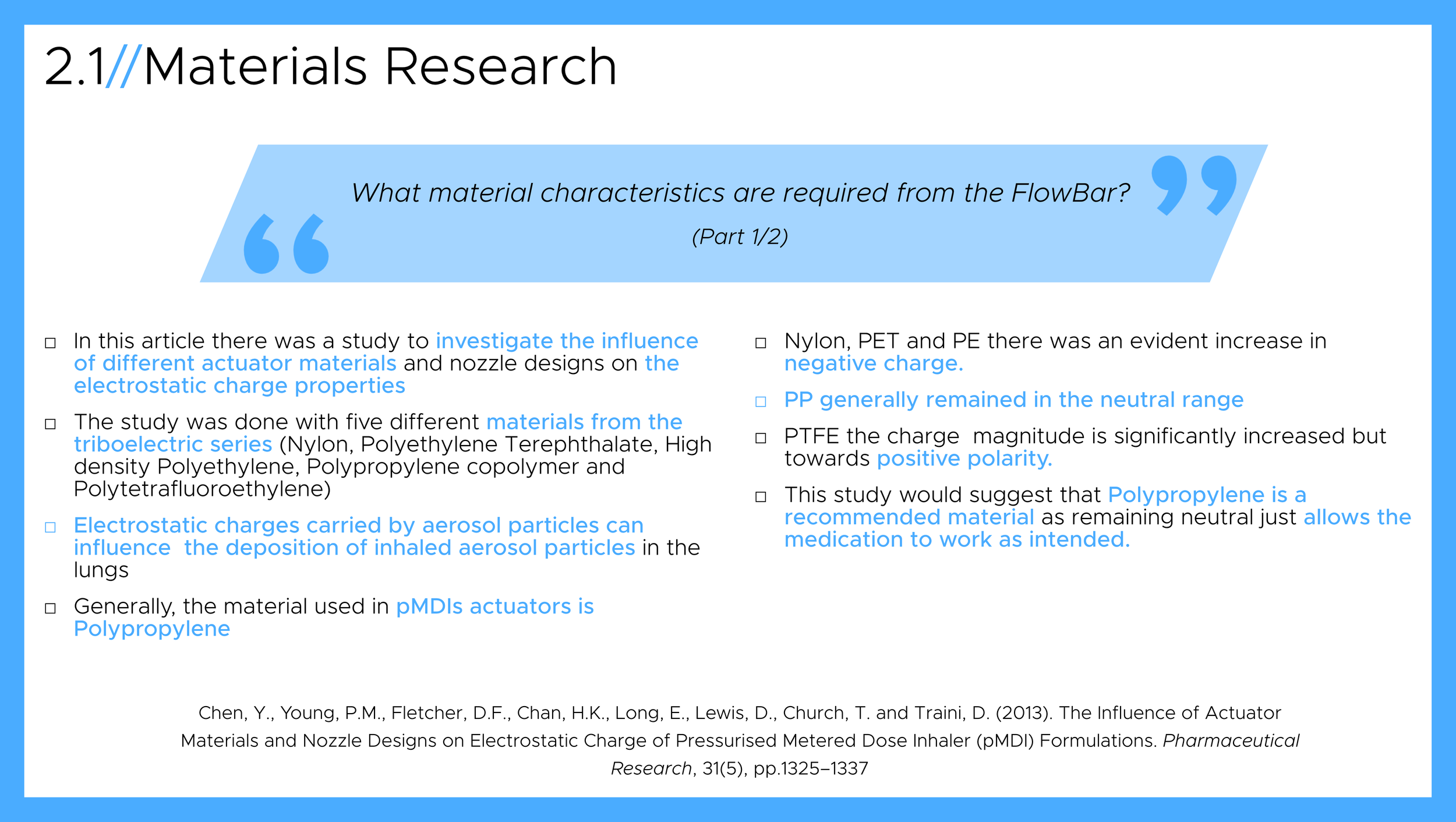

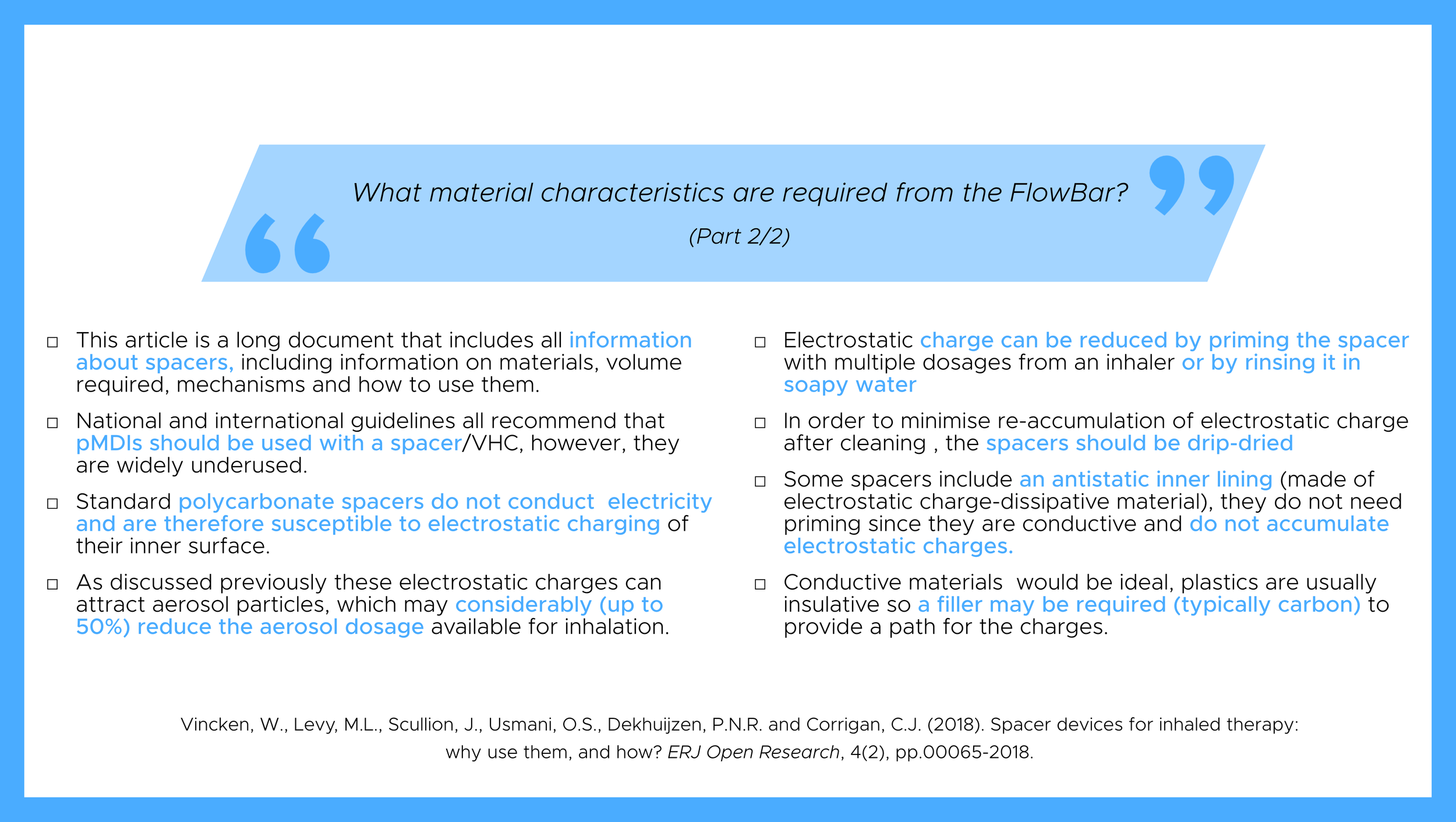

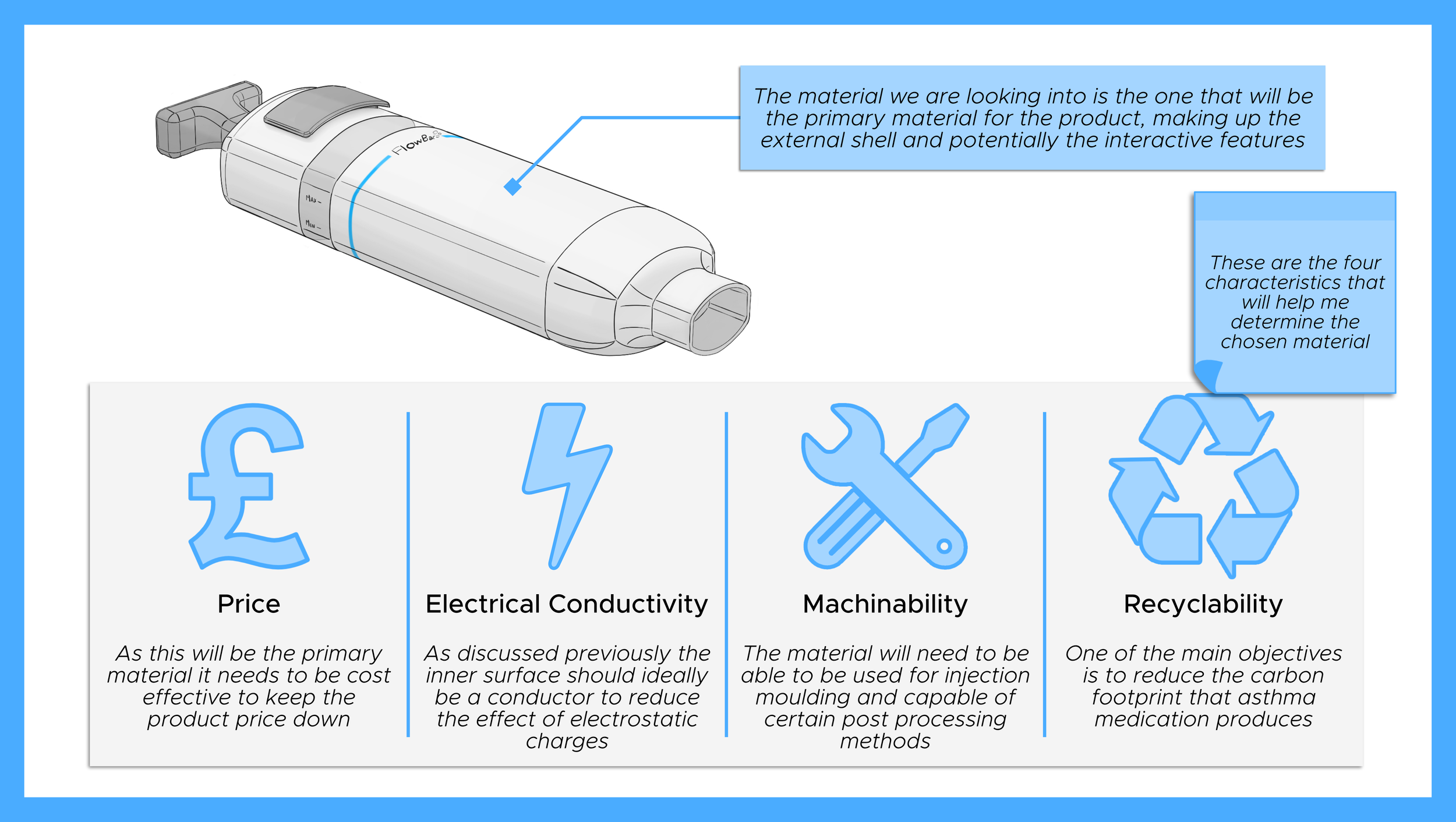

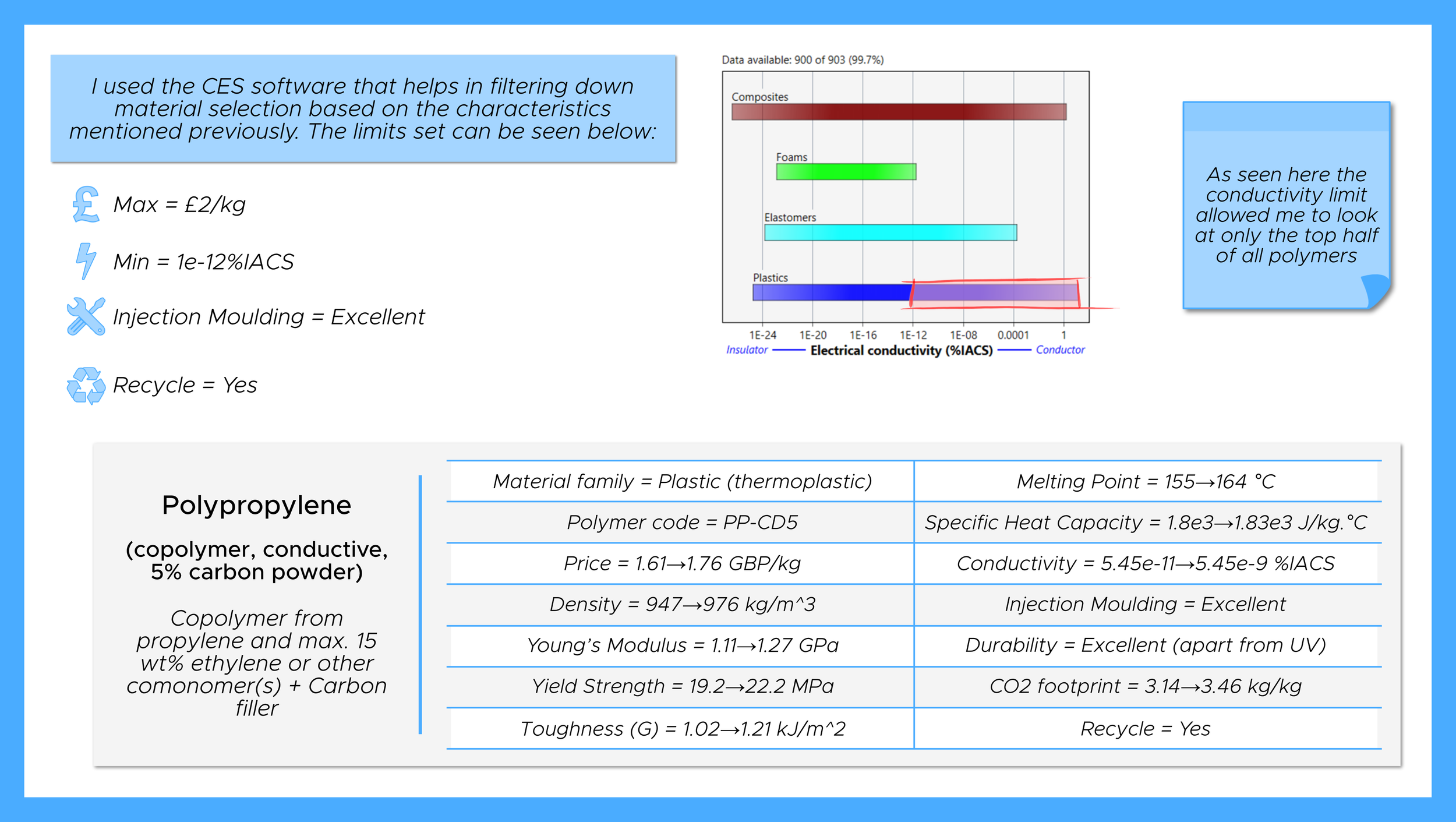

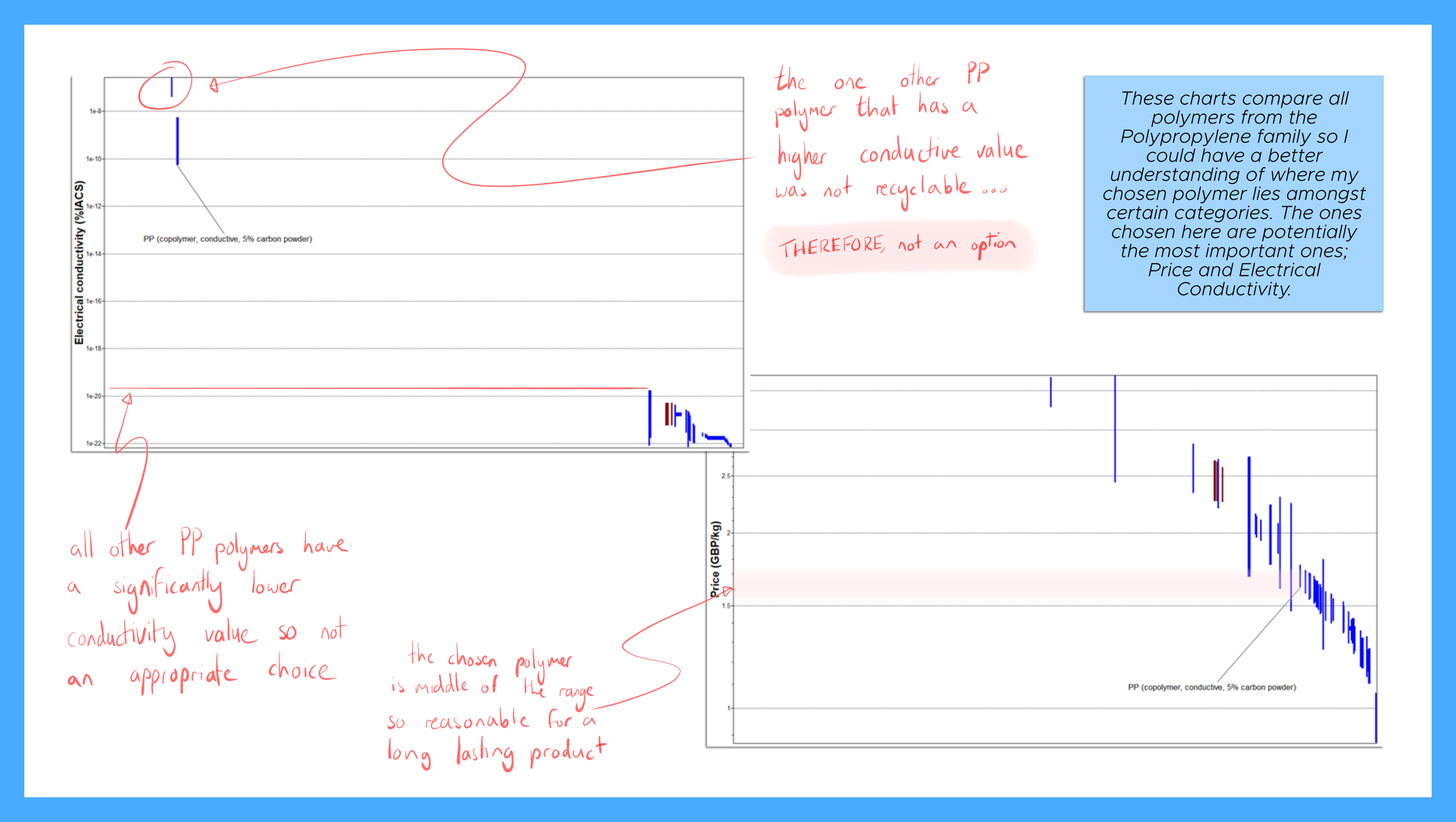

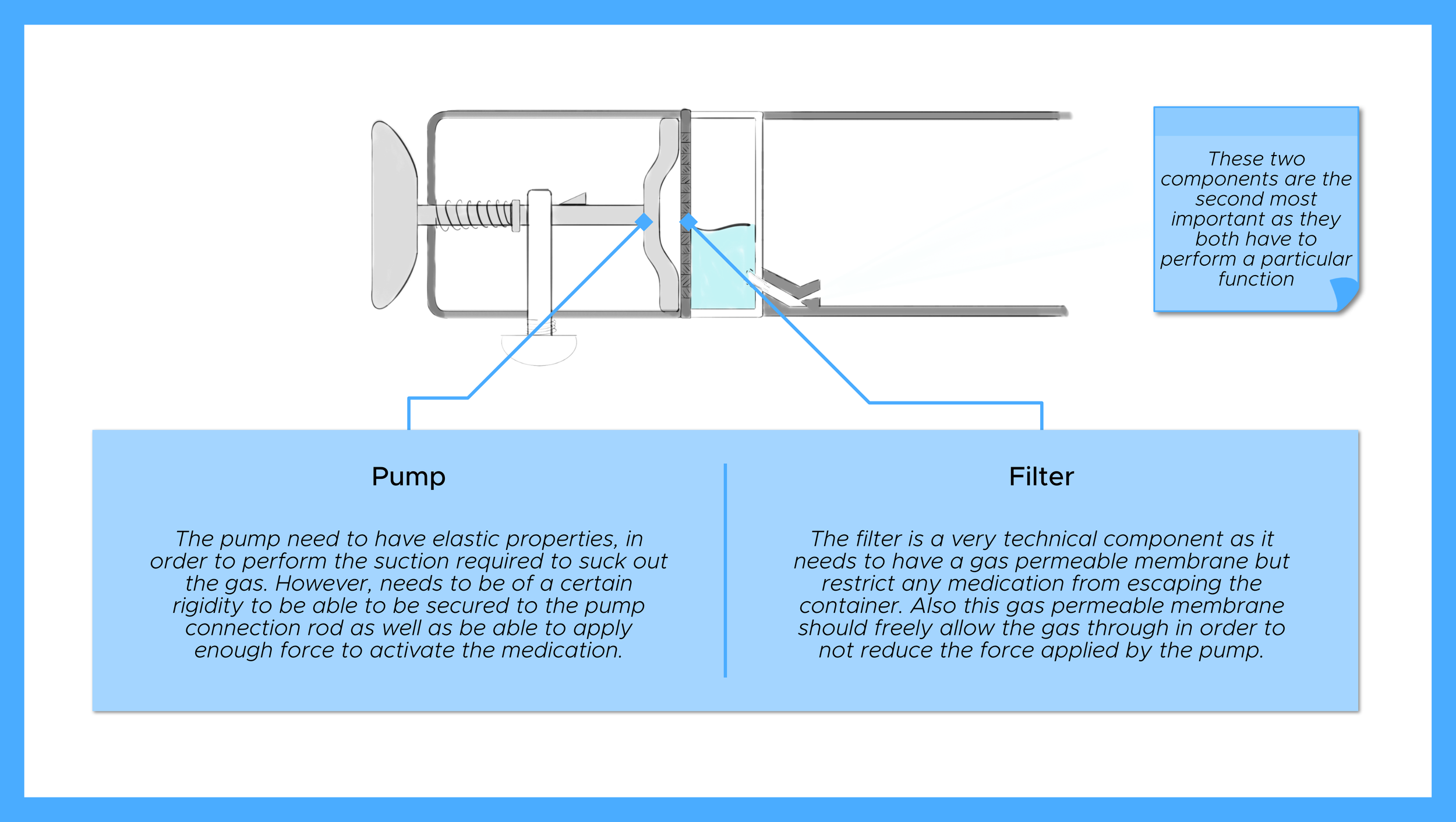

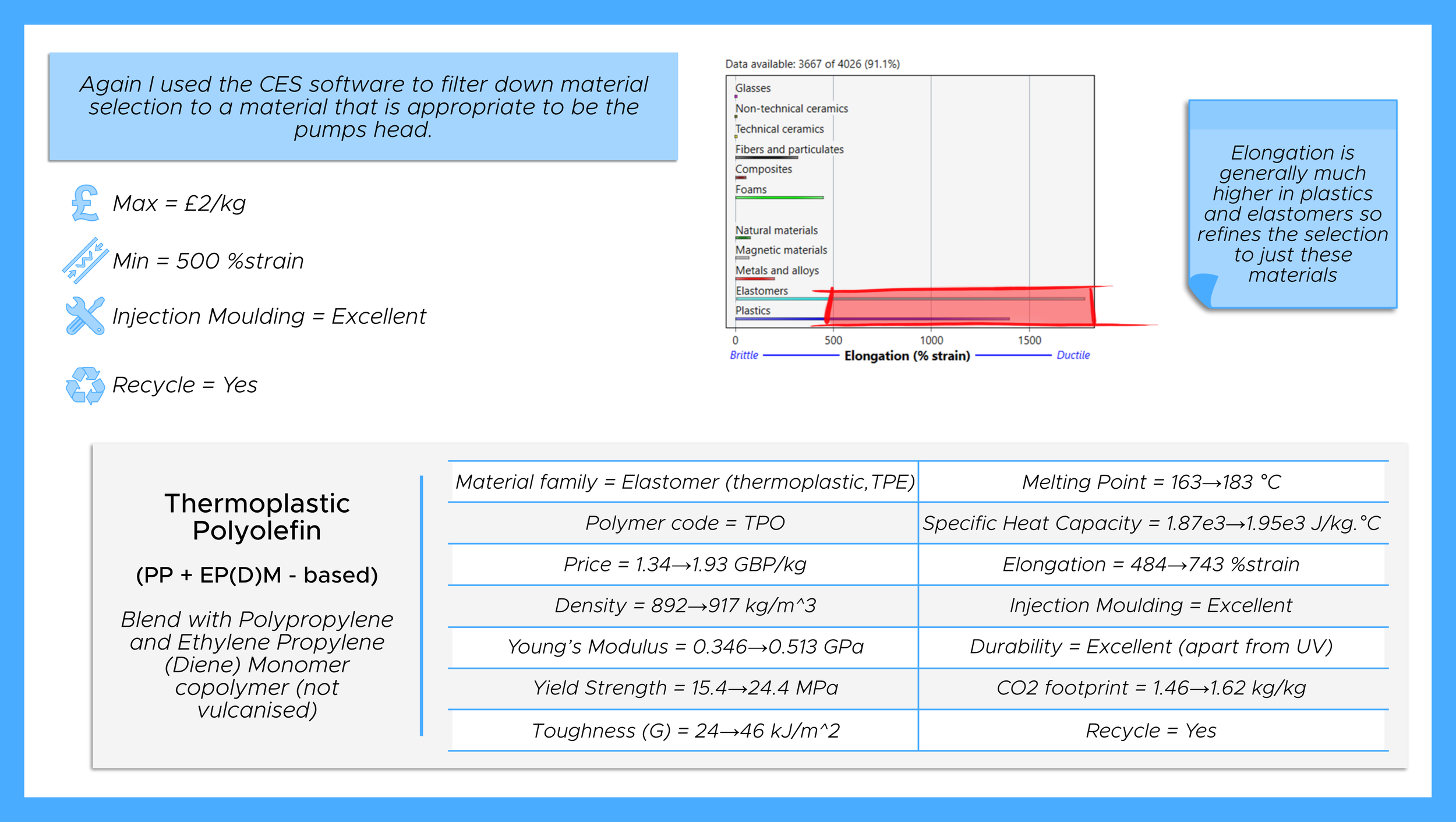

The deep dive into materials development to determine what material is best suited to my product, for this I used the CES material software.

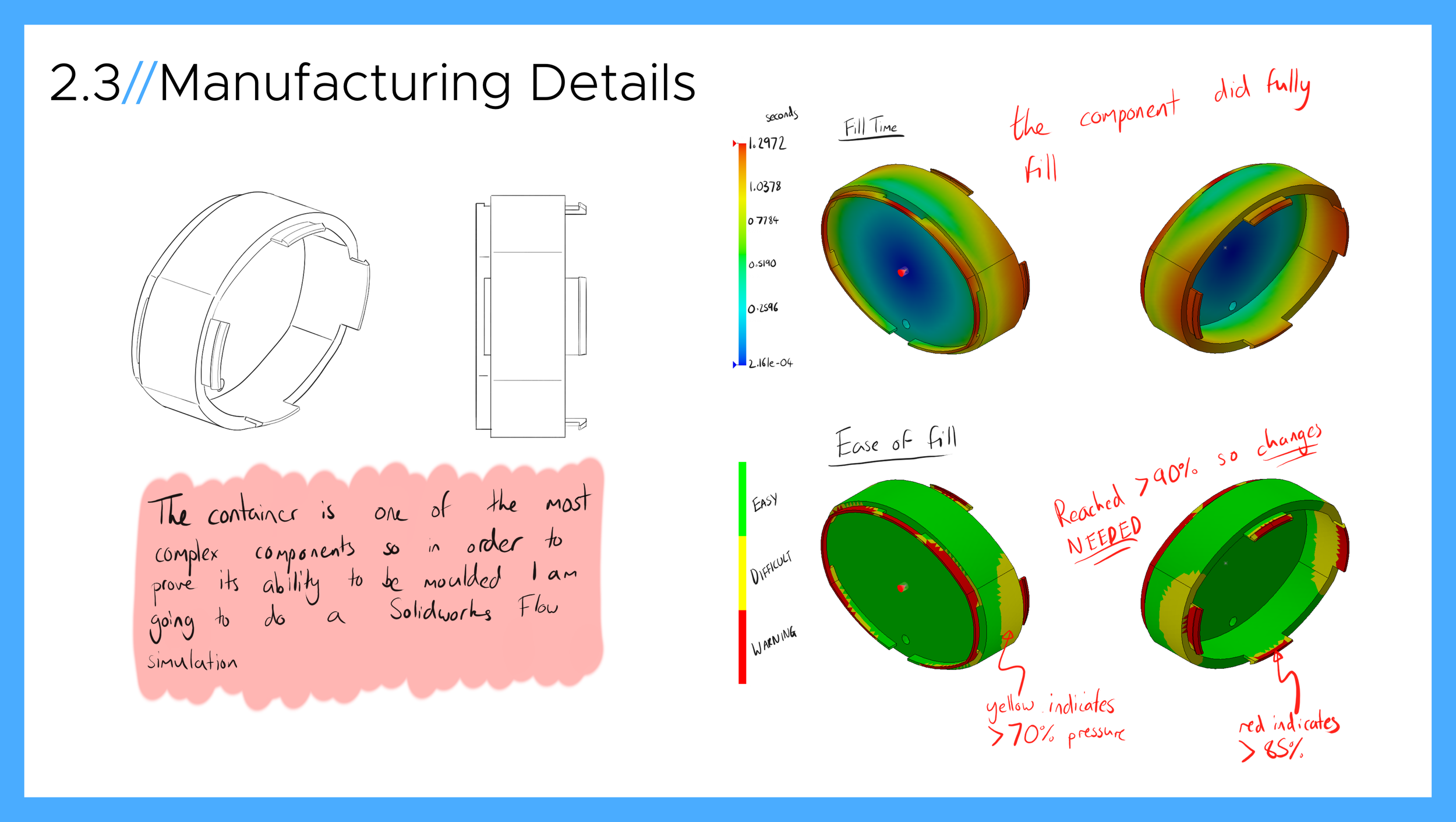

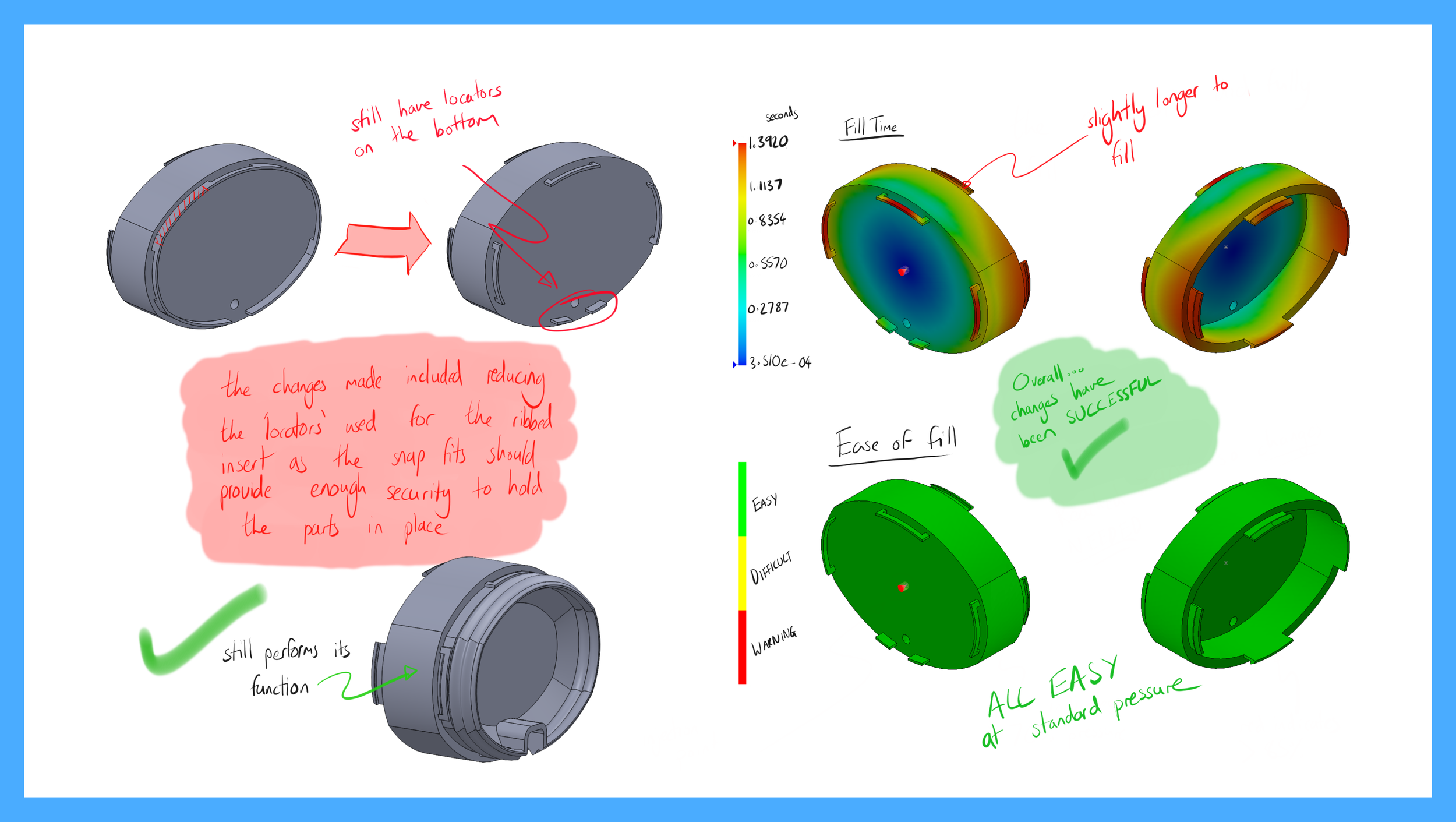

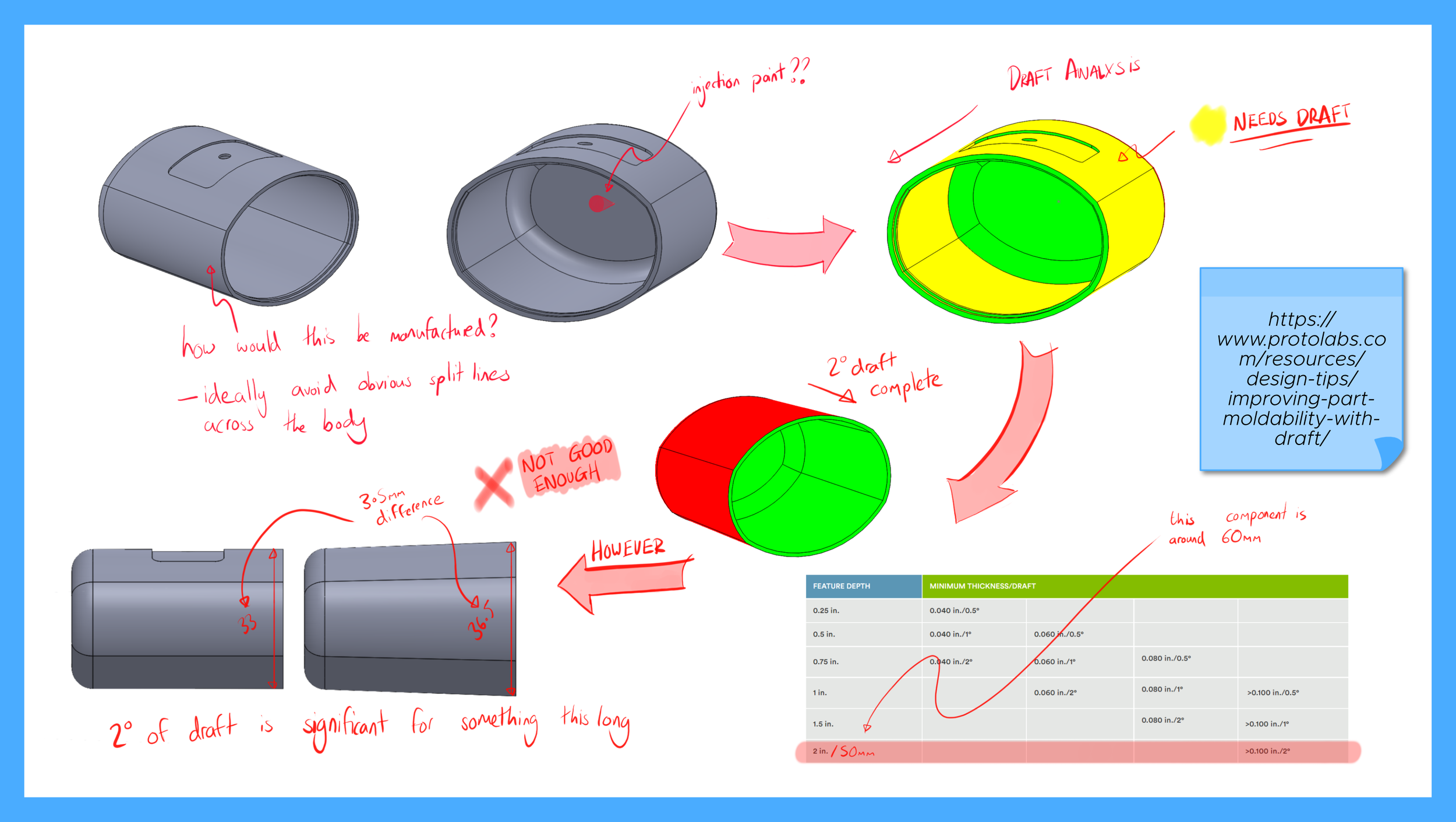

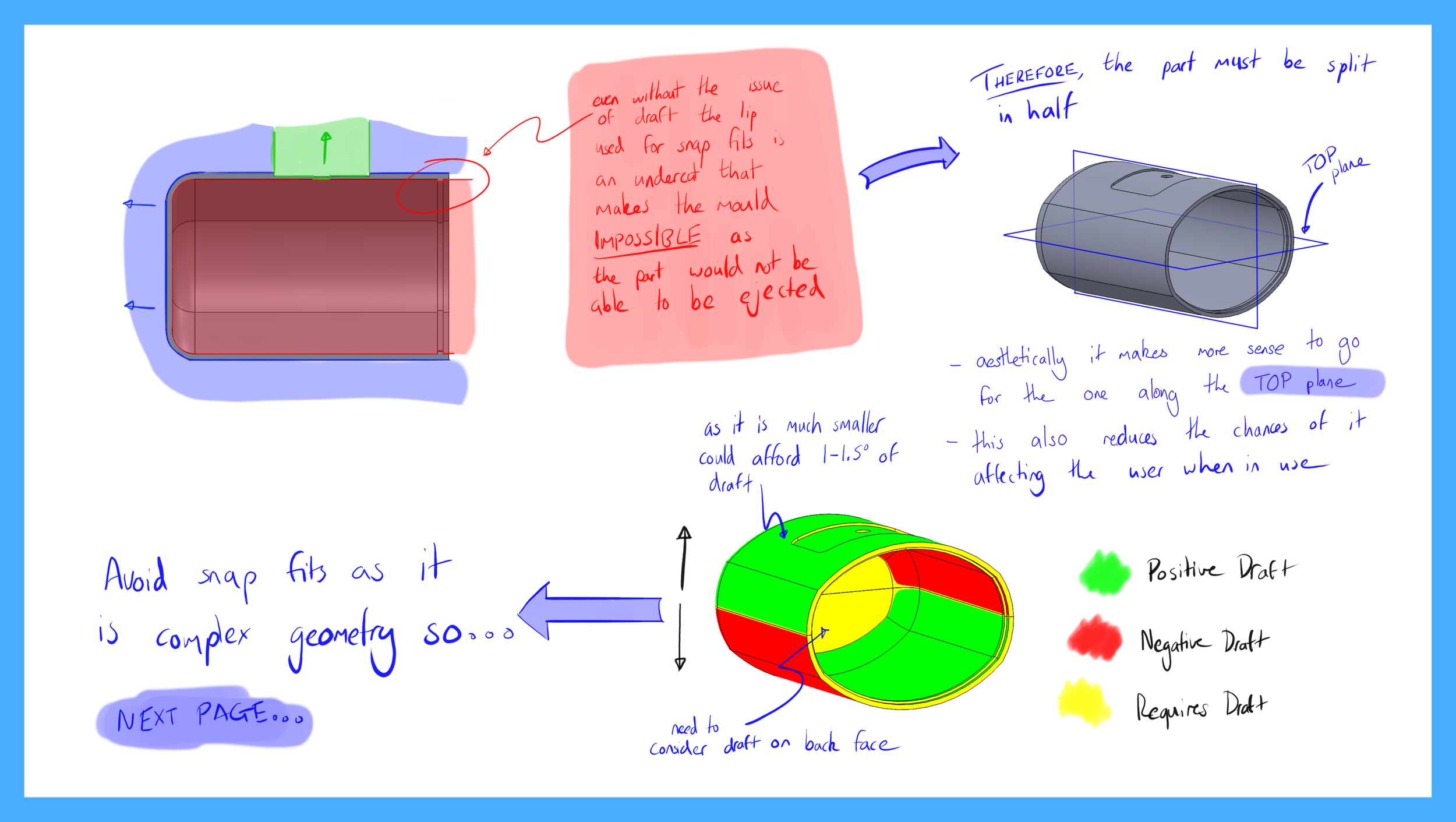

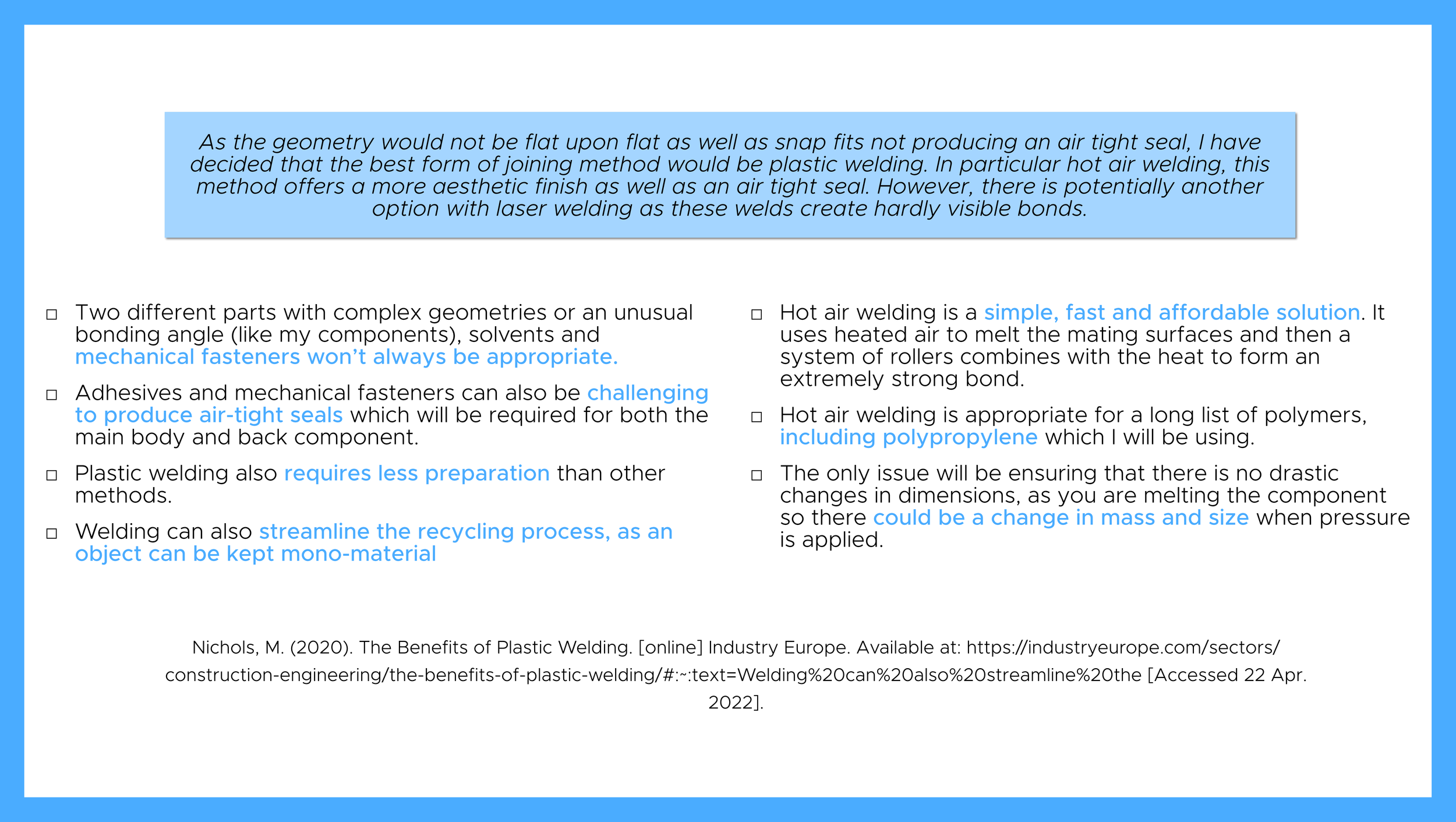

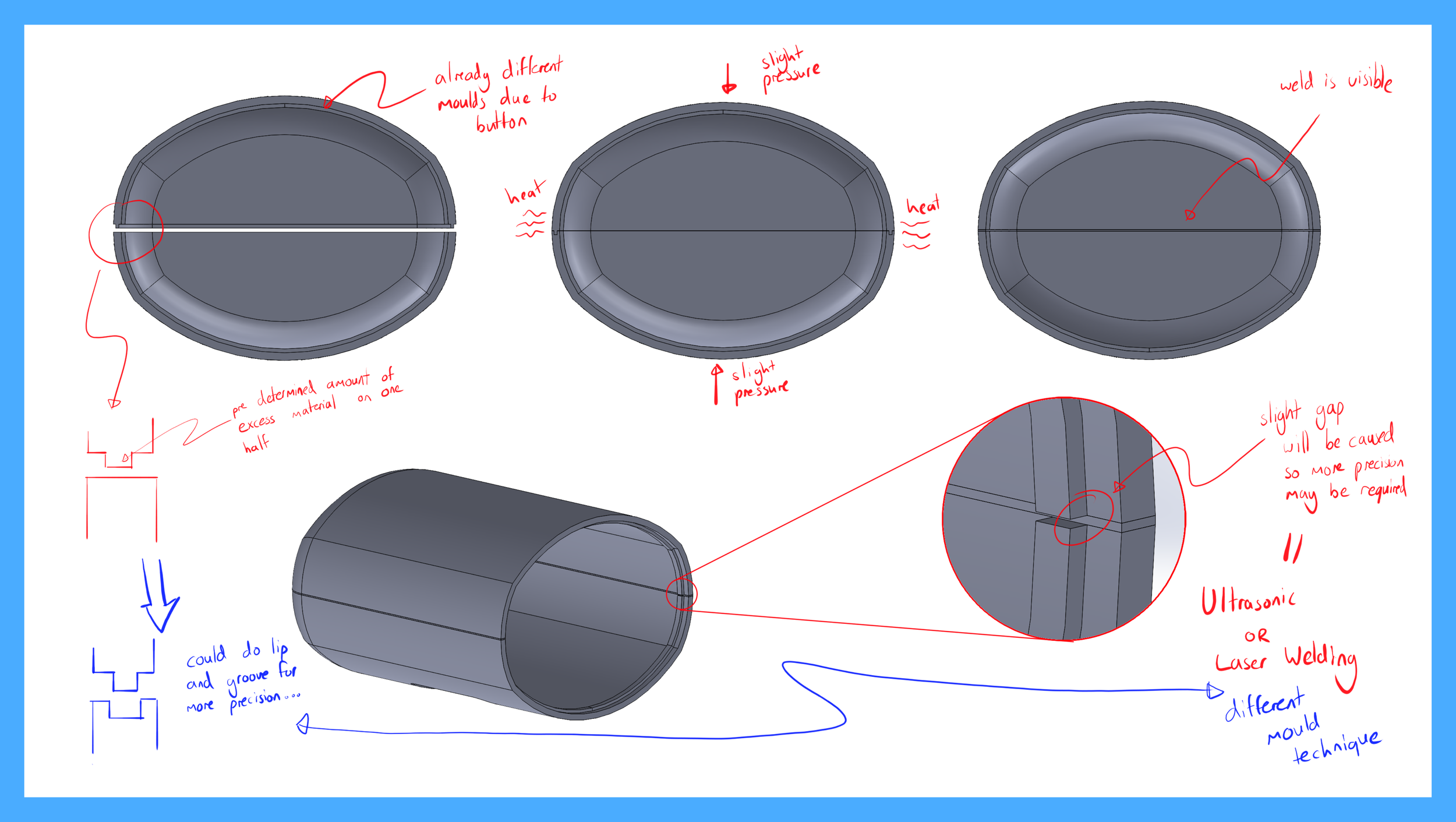

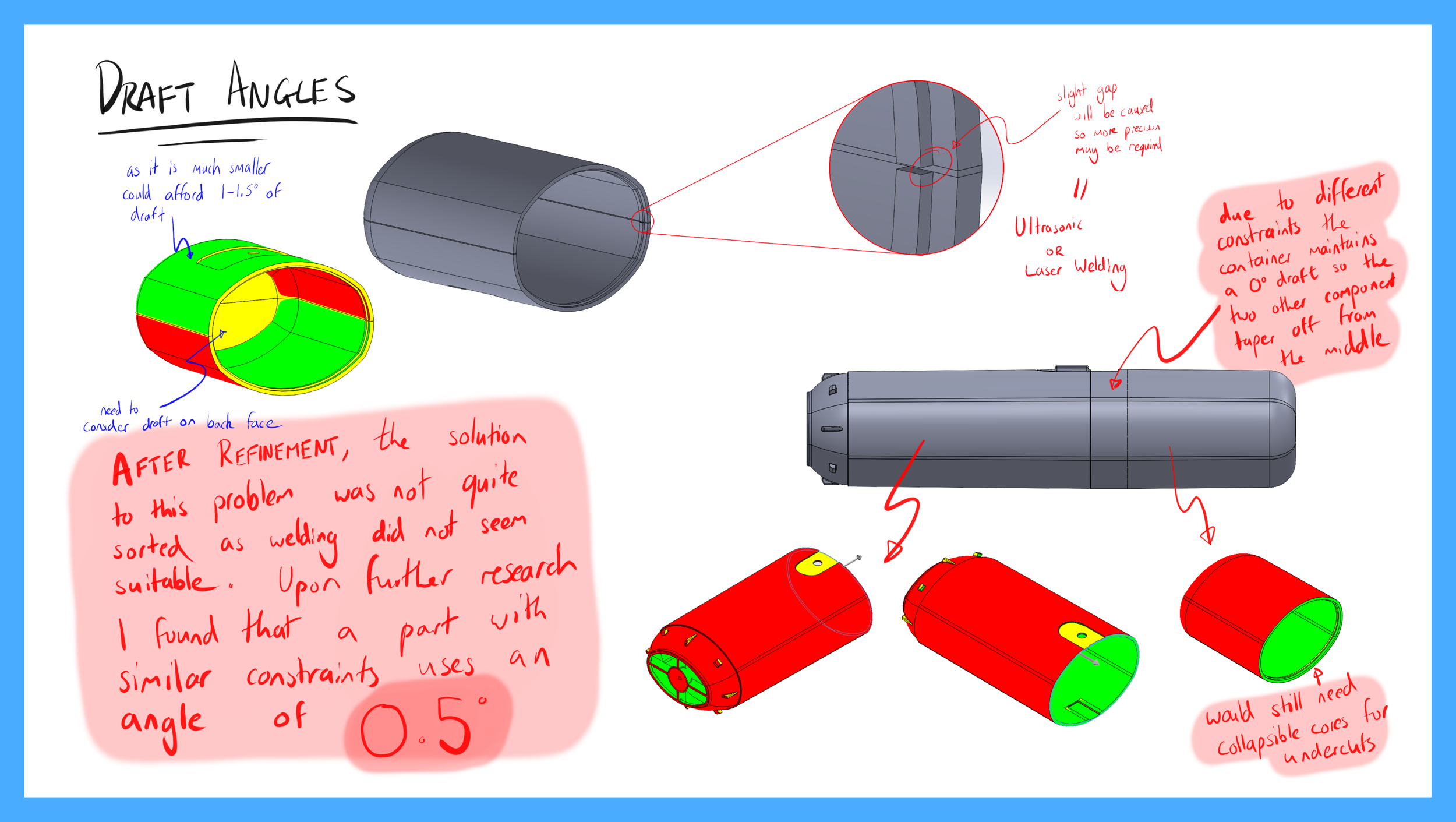

A look into manufacturing development, which looked at draft angles, ease of fill and the assembly of the product using a variety of techniques including CAE analysis.

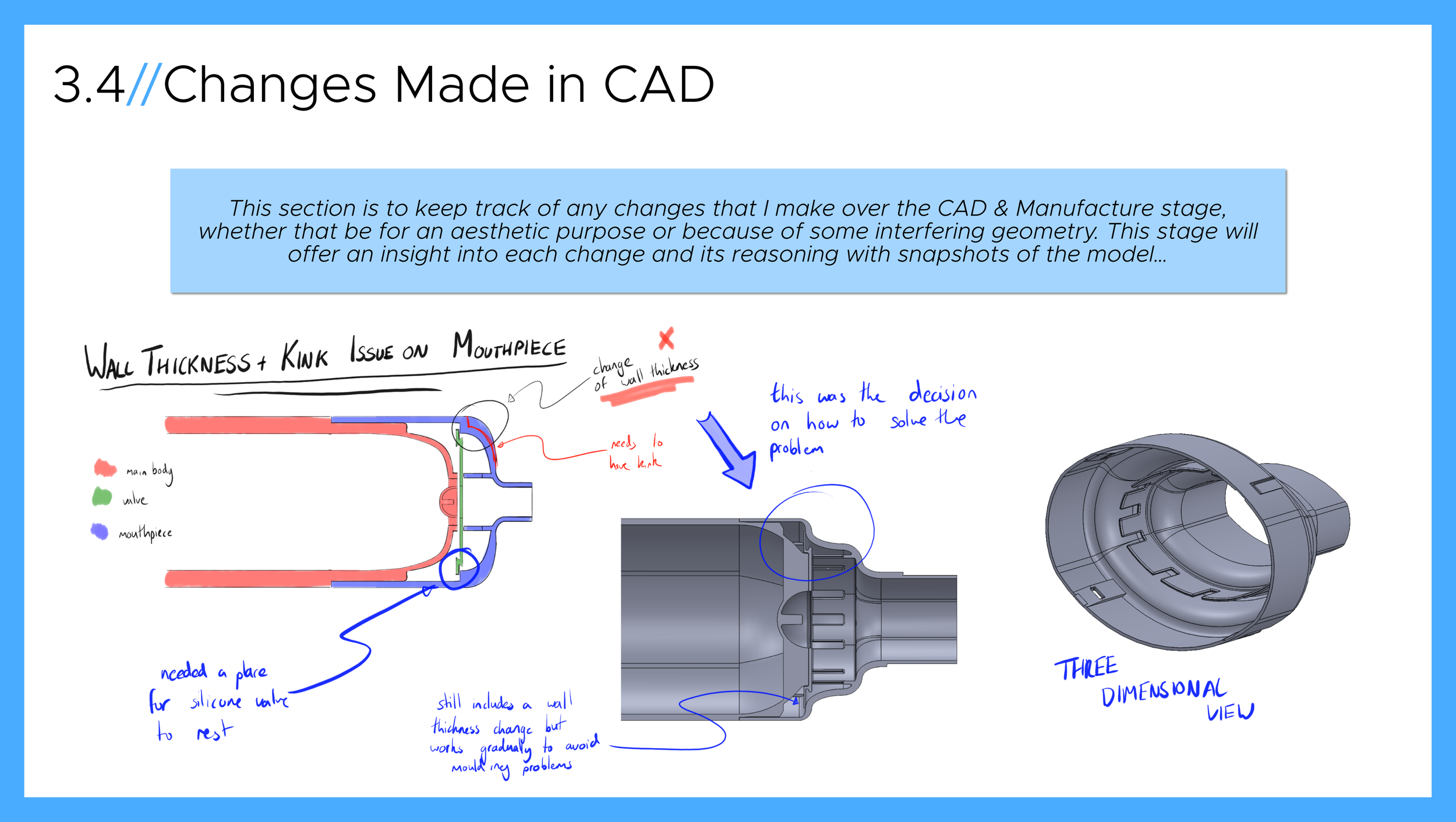

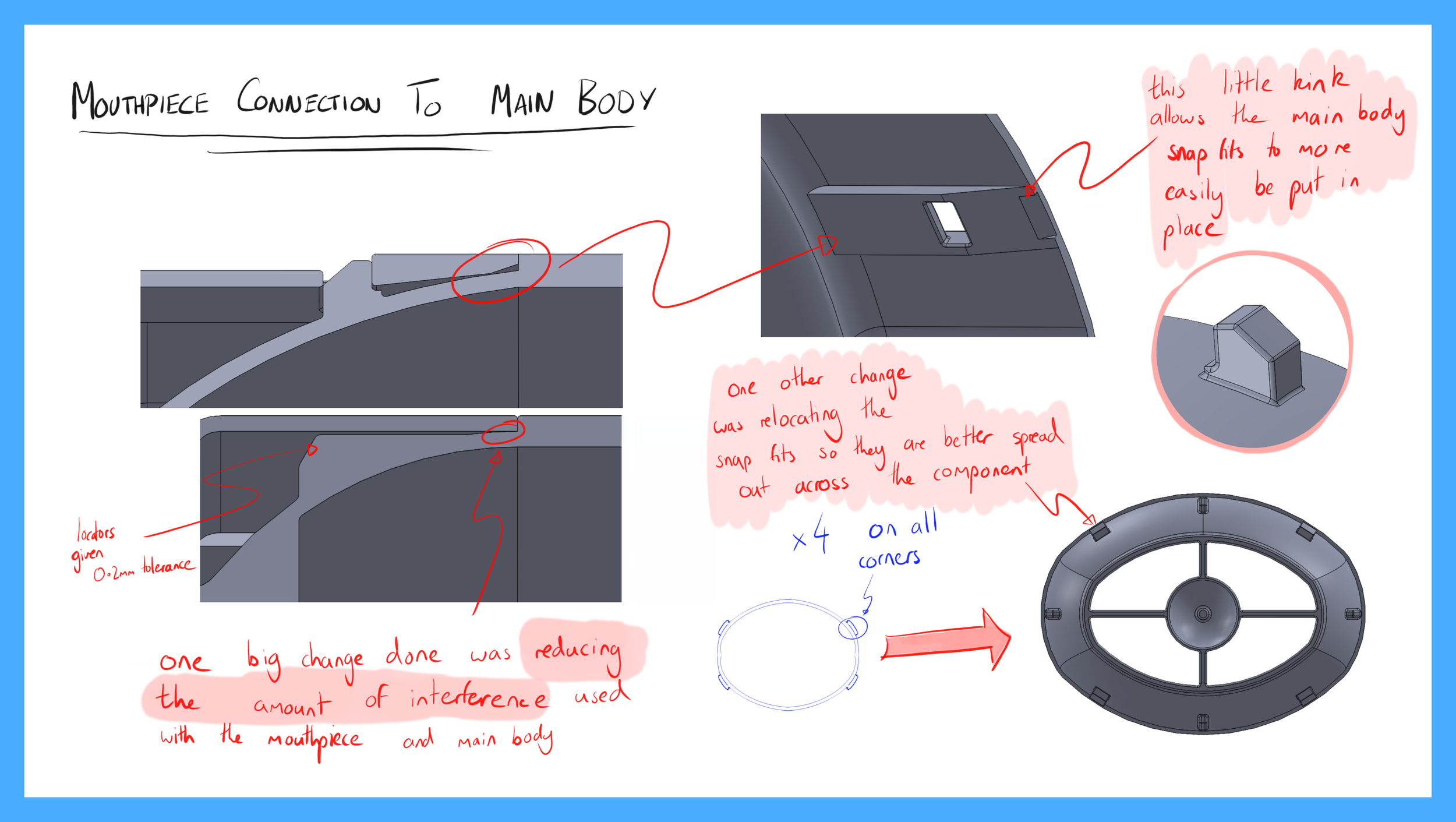

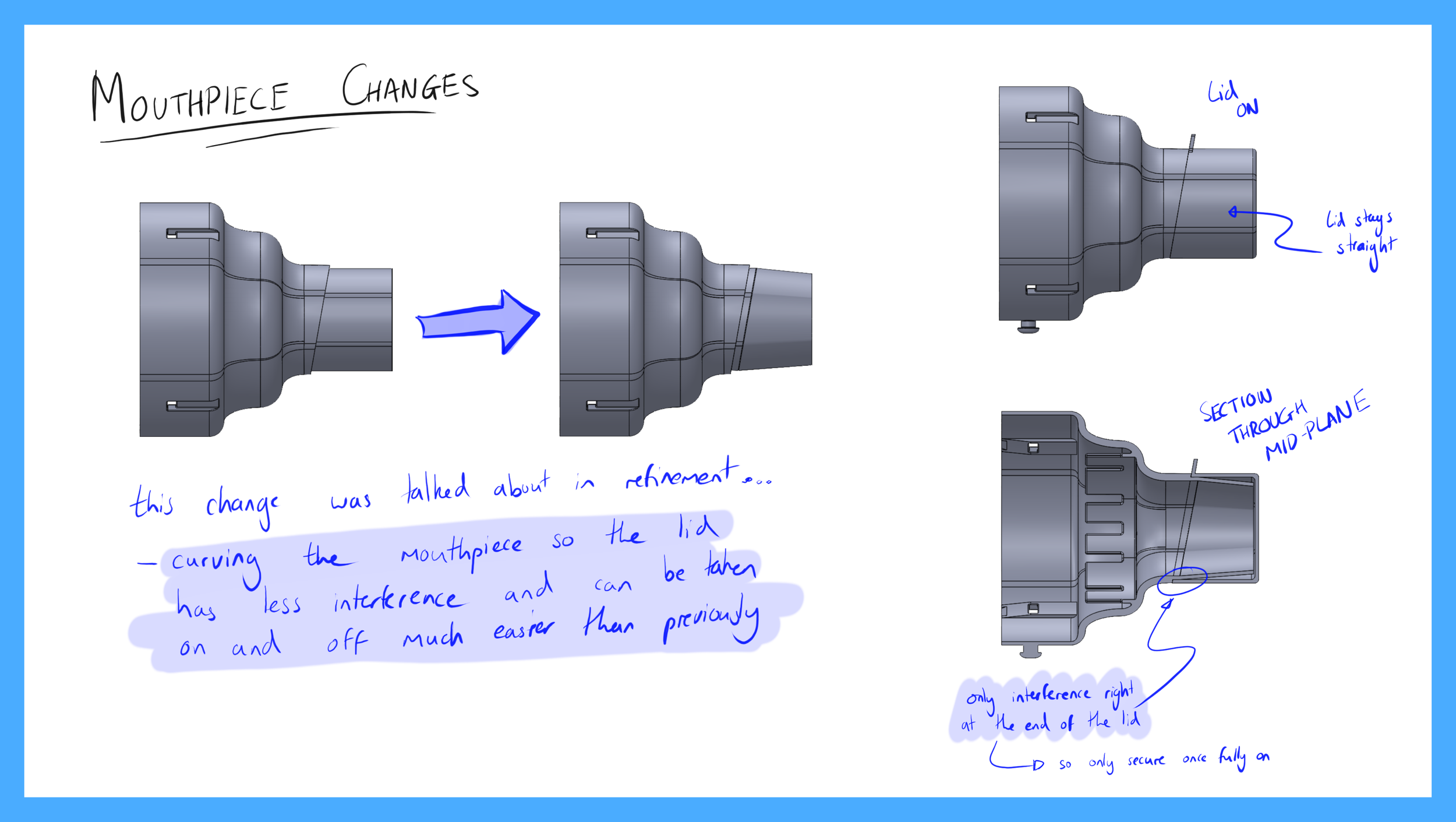

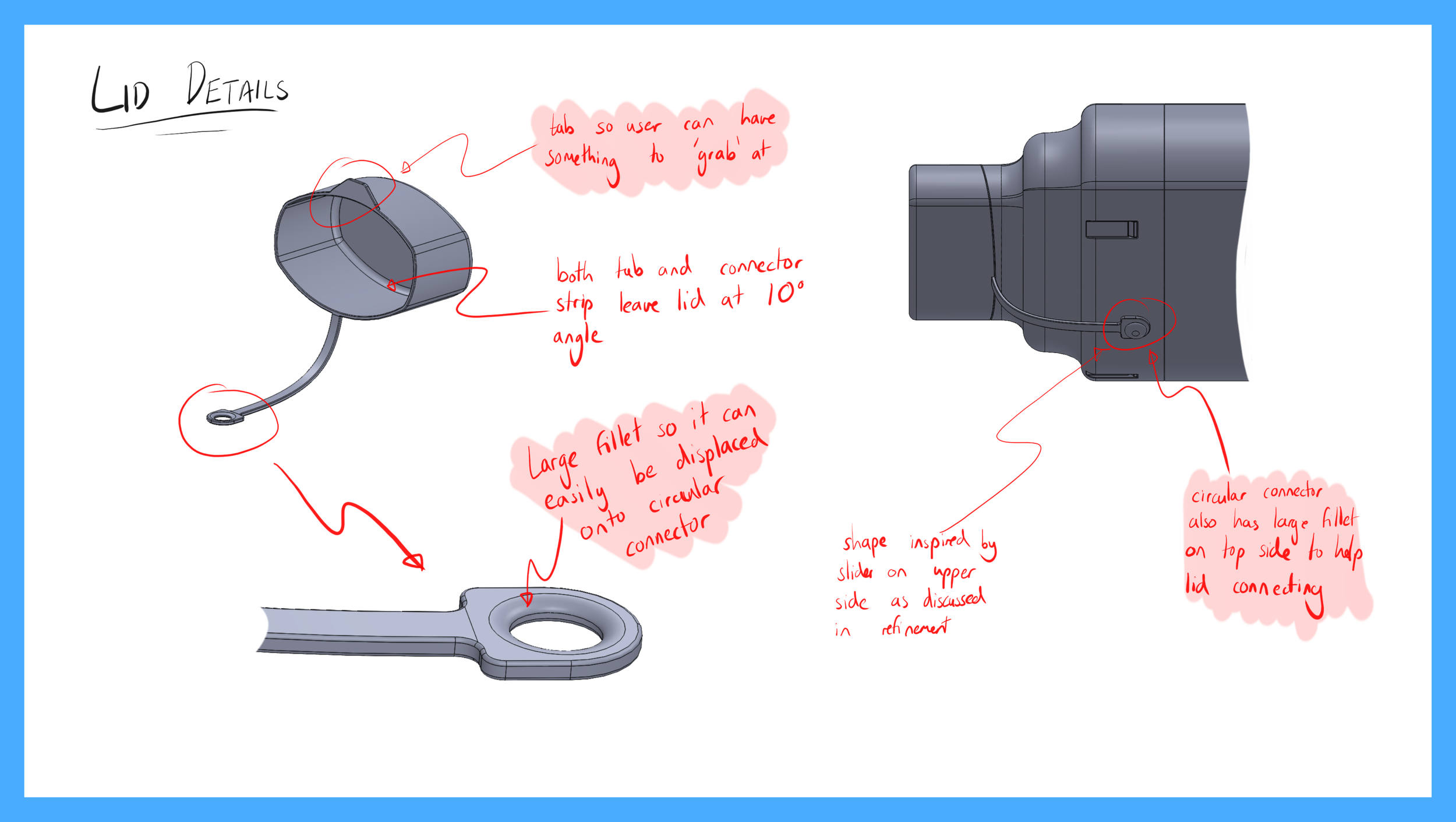

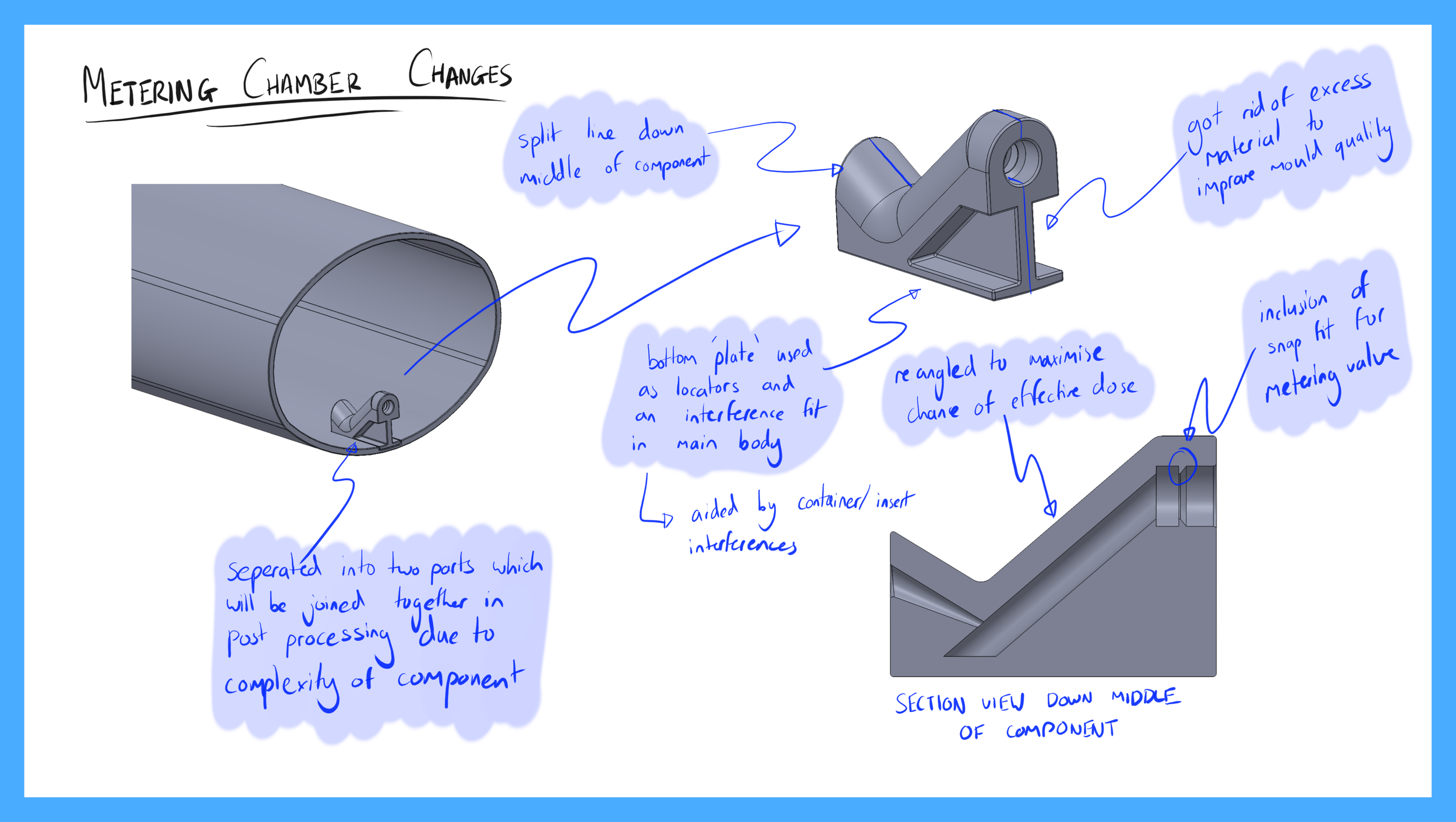

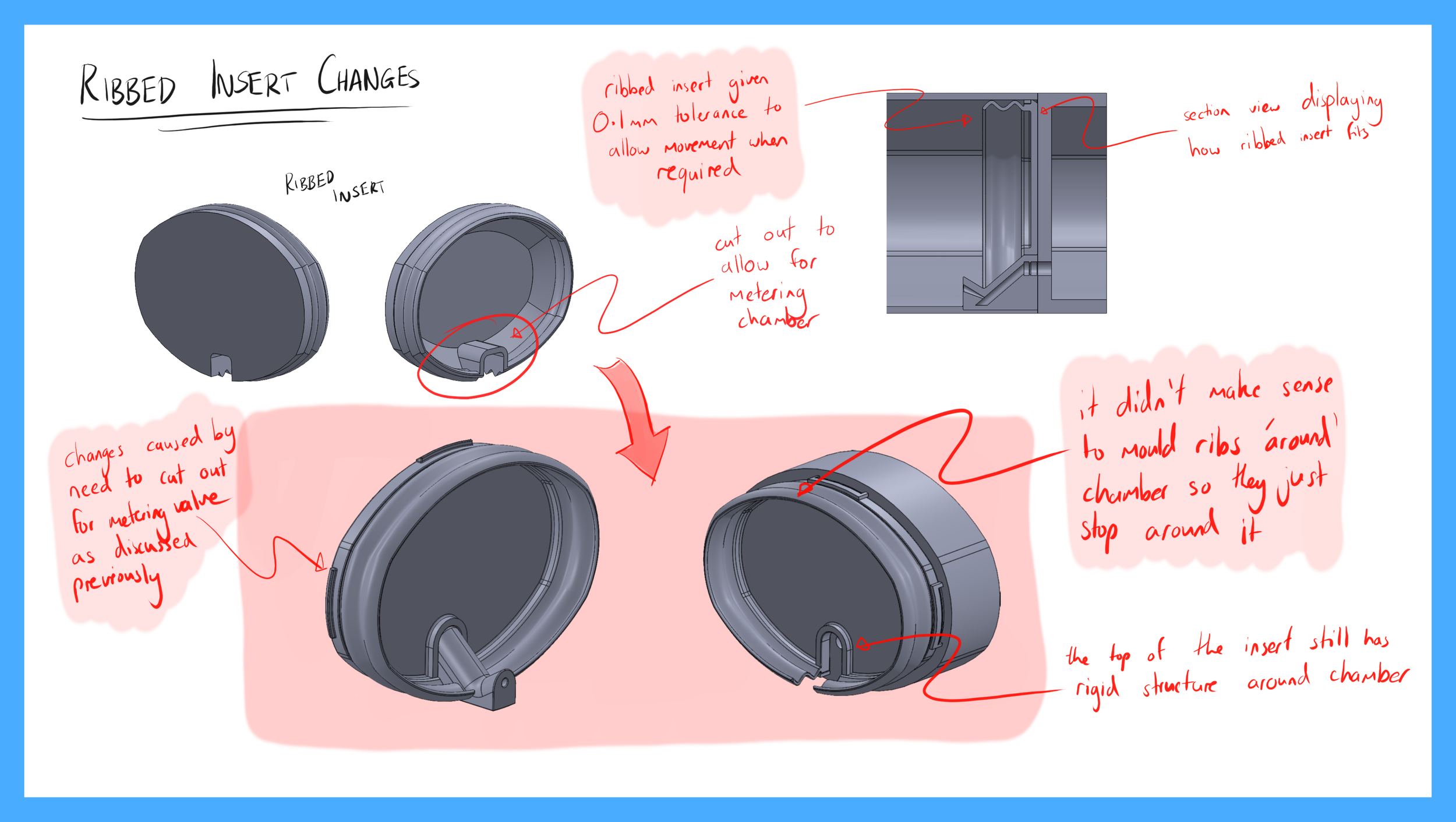

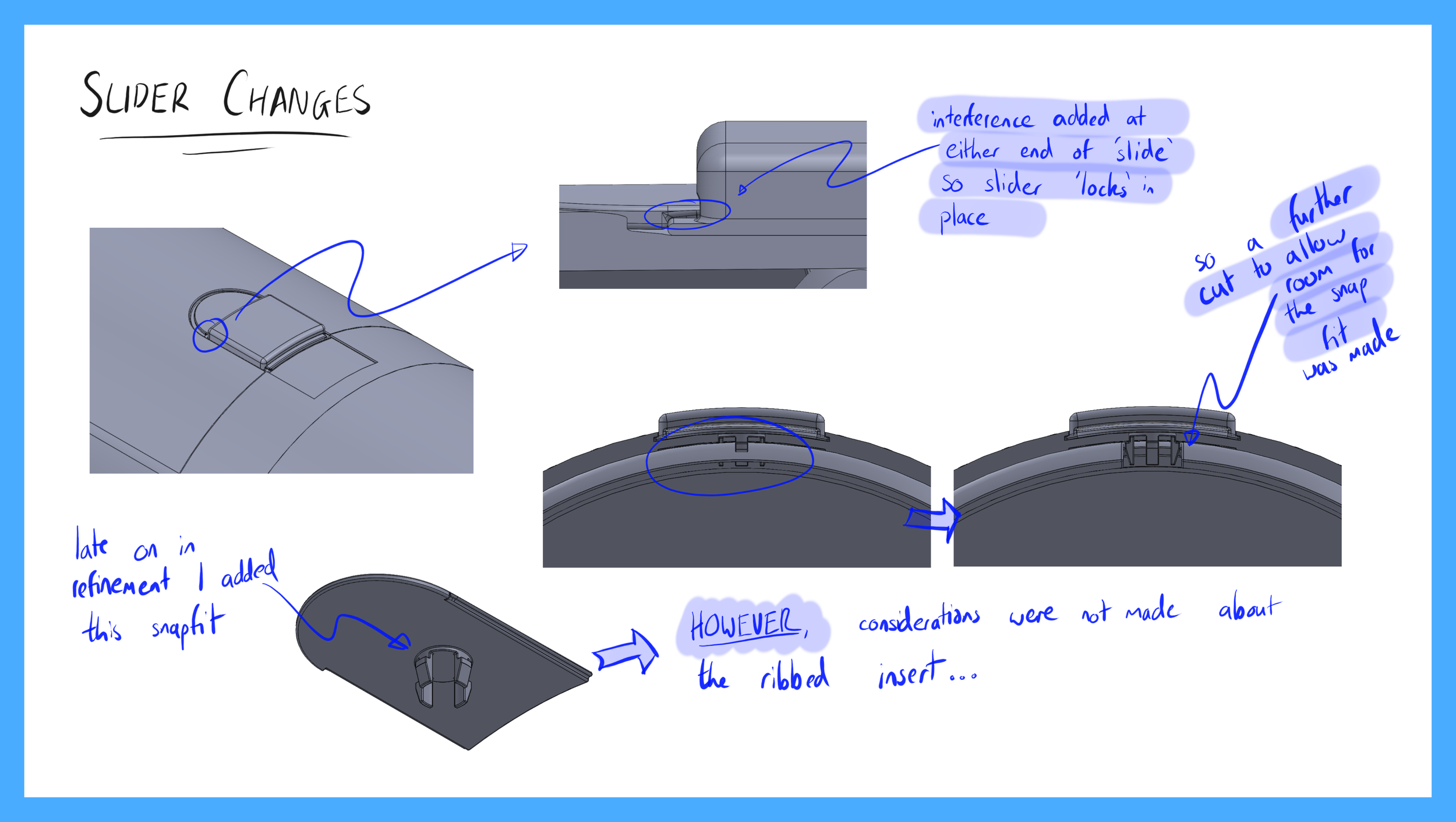

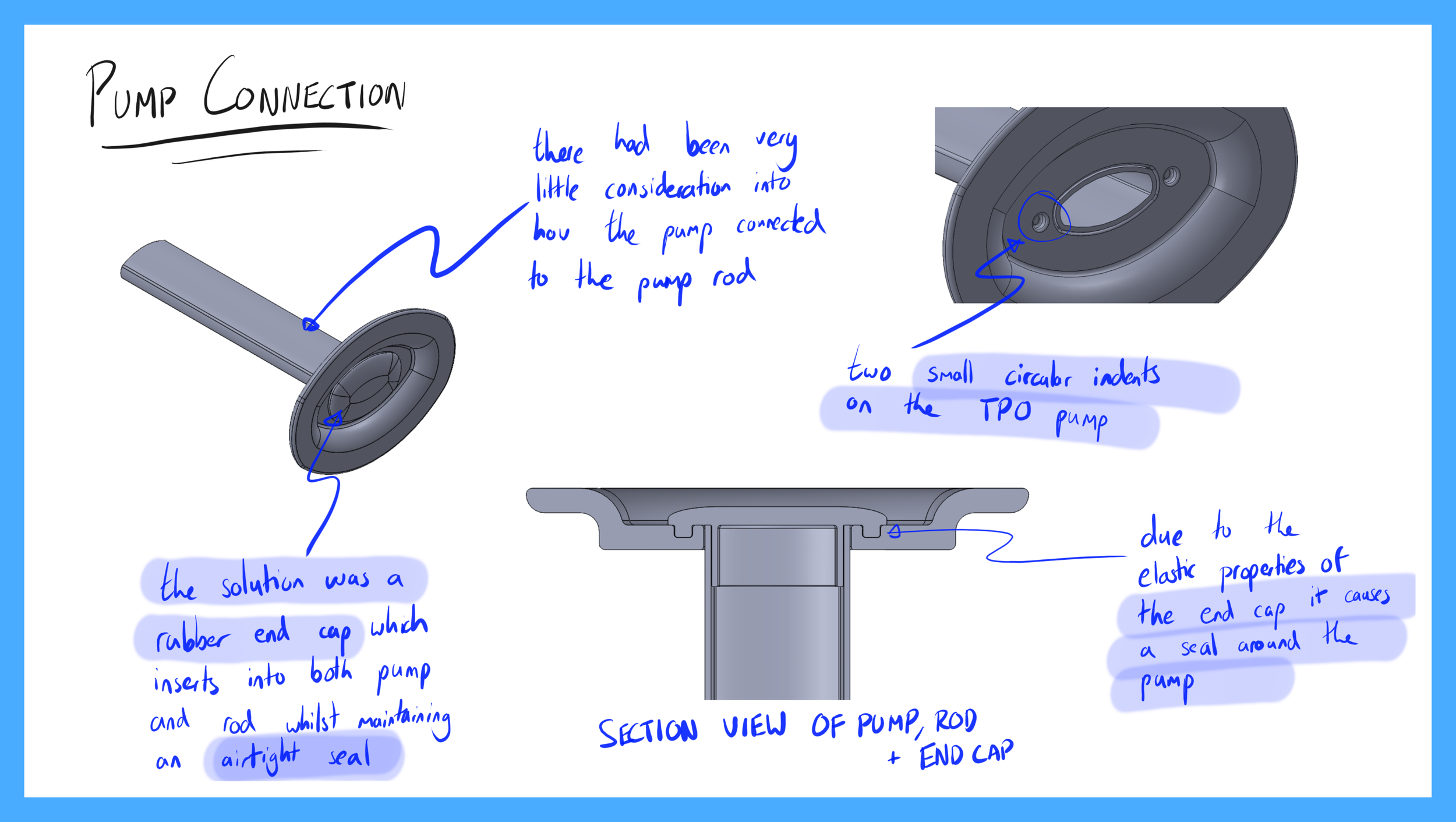

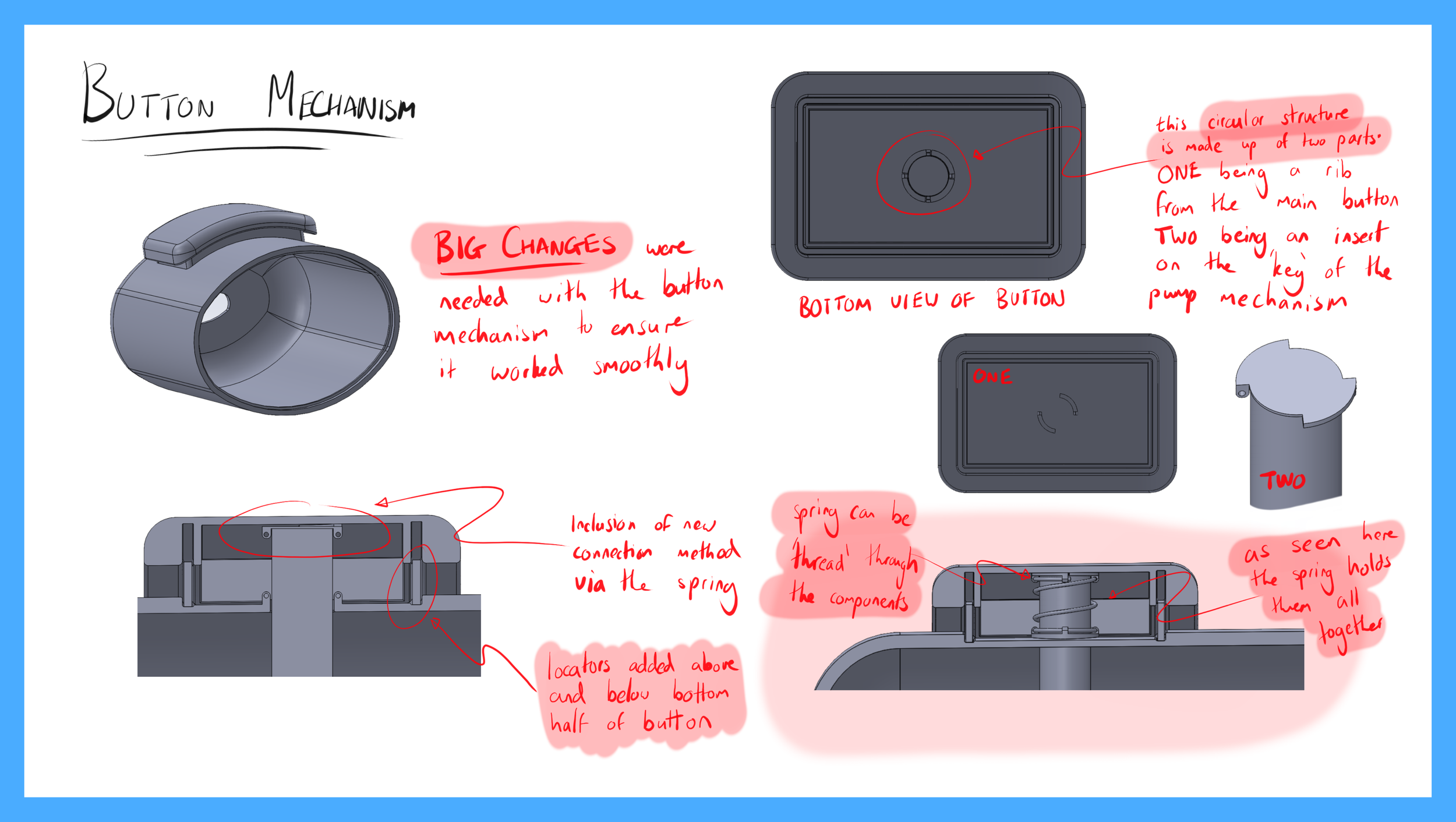

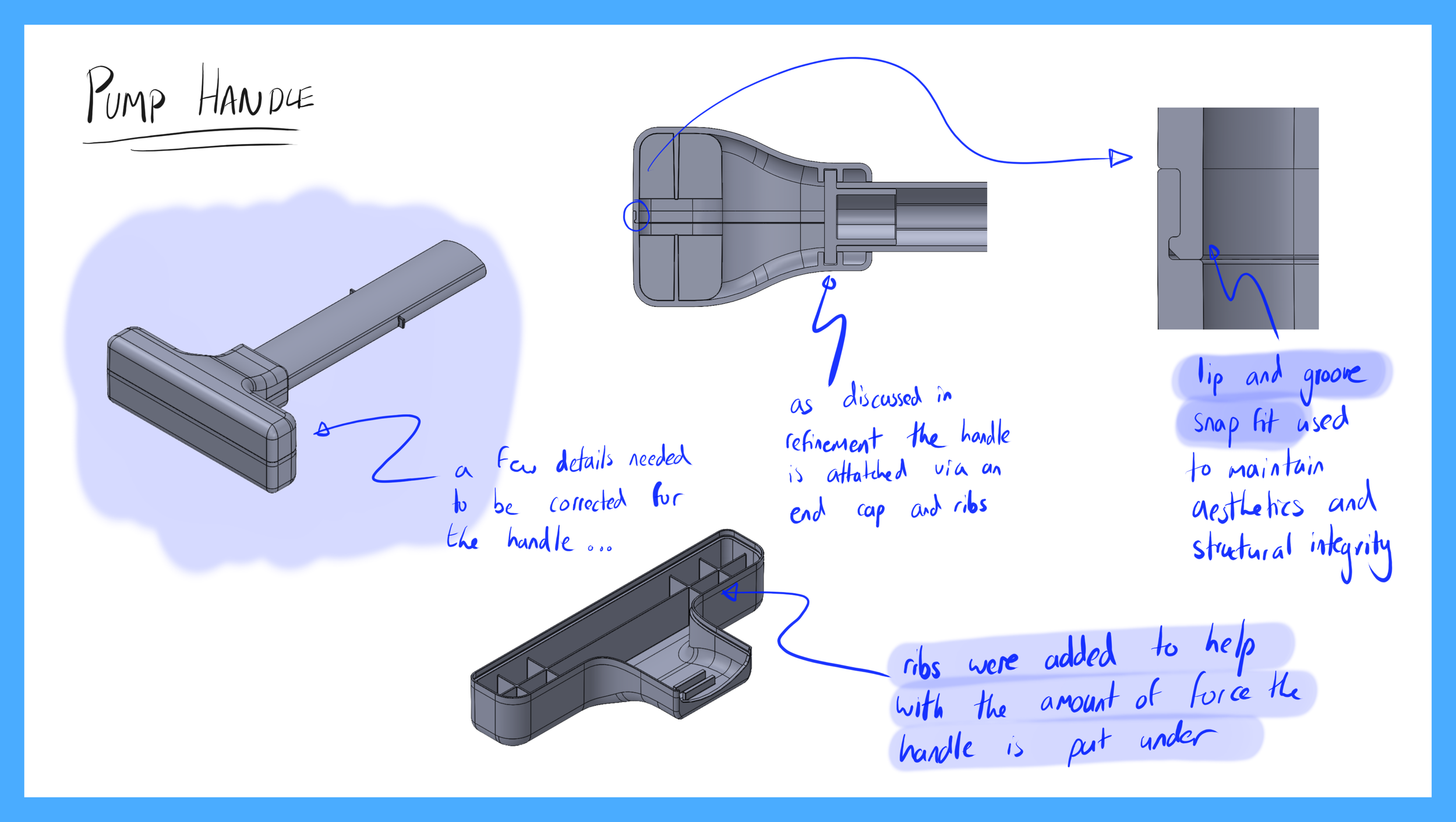

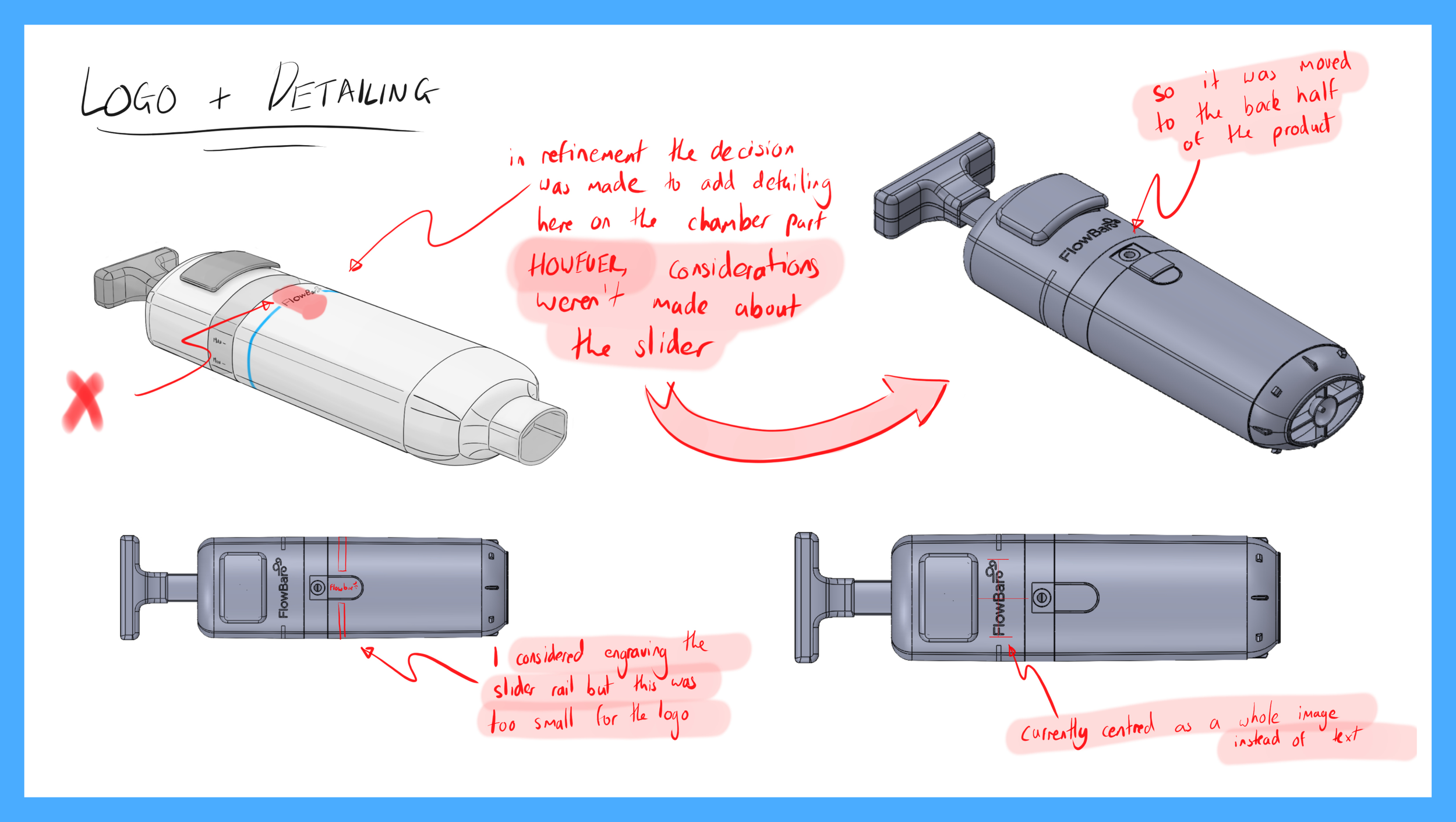

Finally there are those last minute CAD changes that once taken into the software become more apparent and necessary as you begin to work fully in 3D

Flowbar Asthma Medication

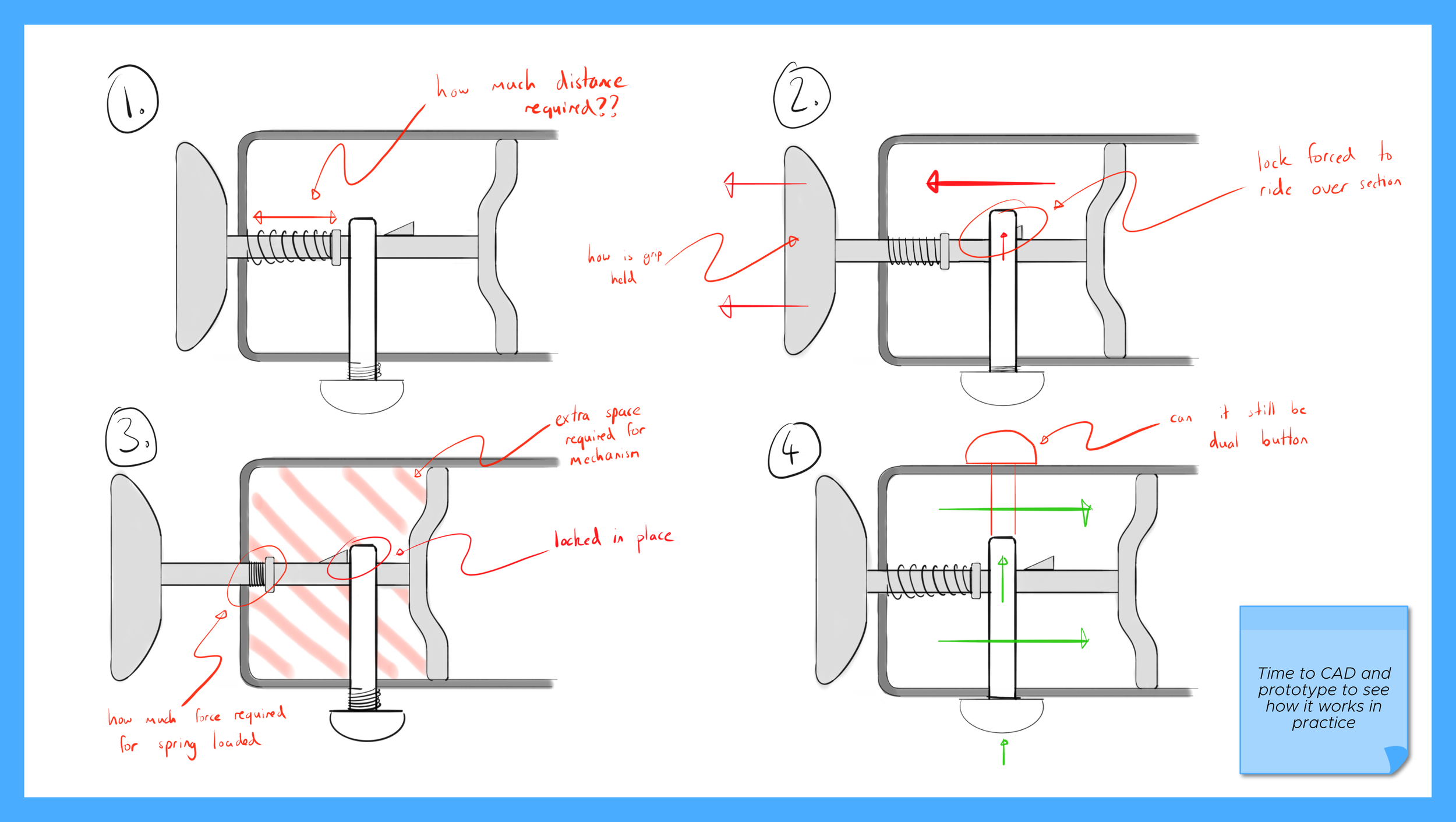

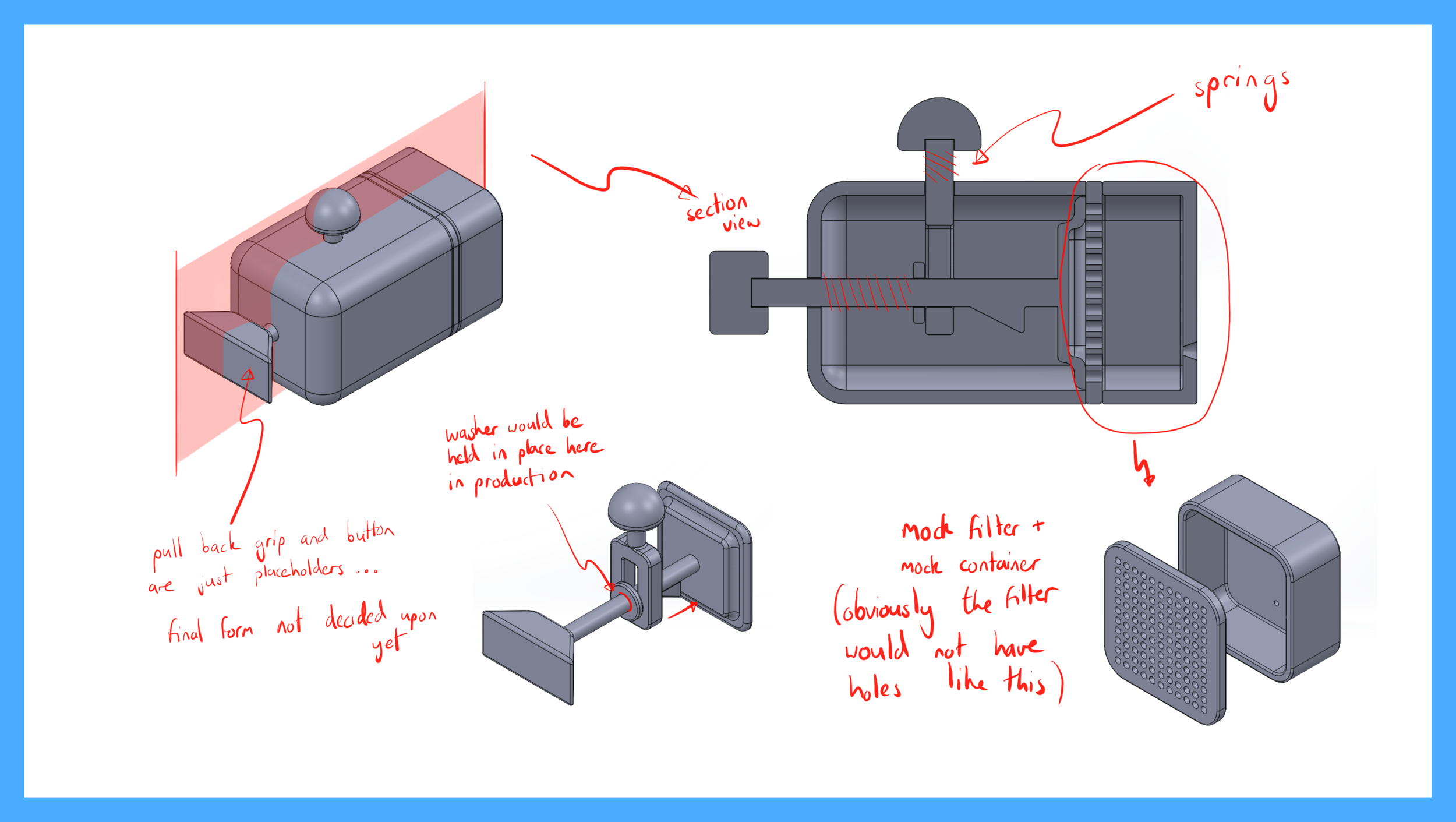

Mechanism Development

User Studies

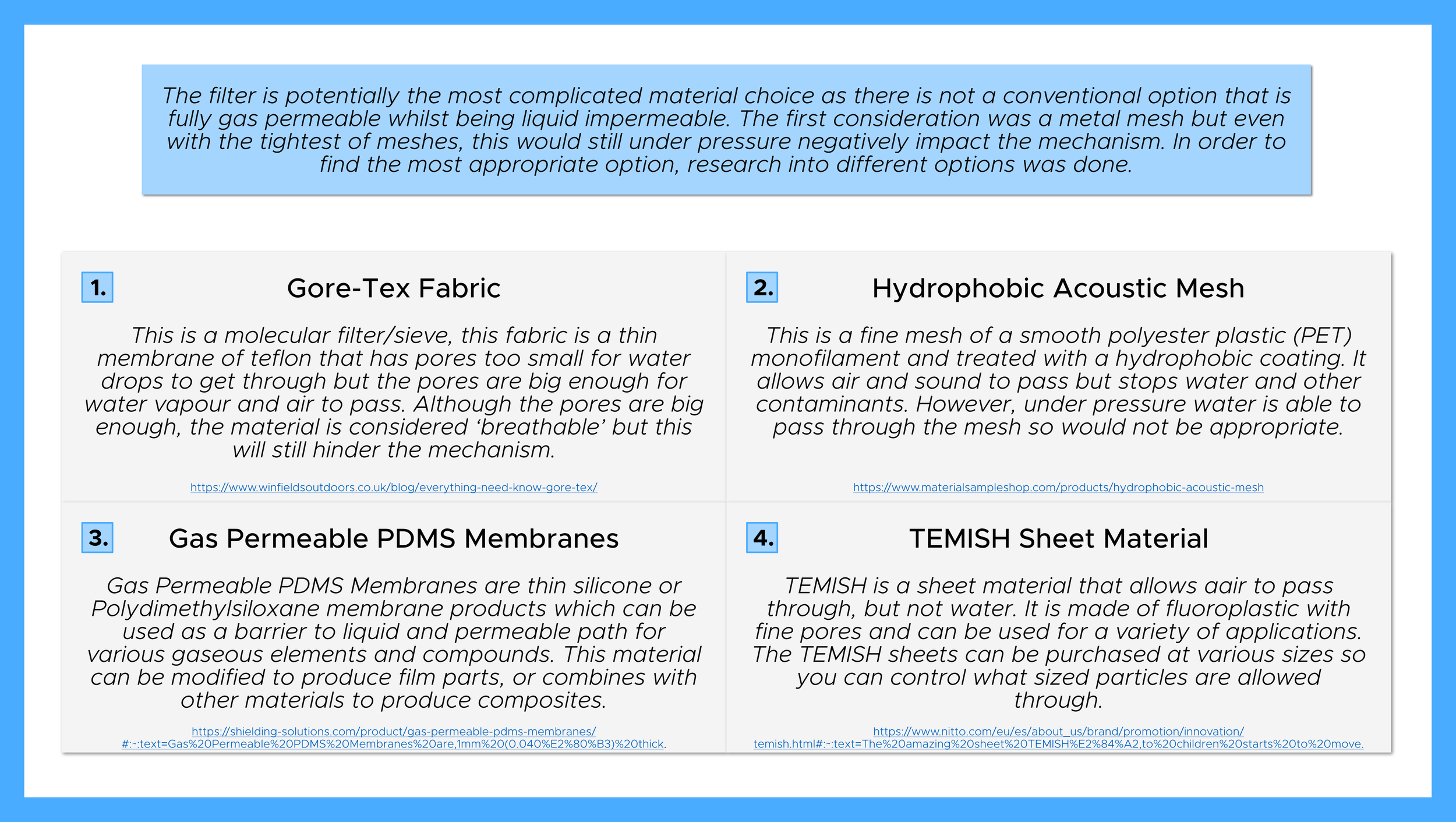

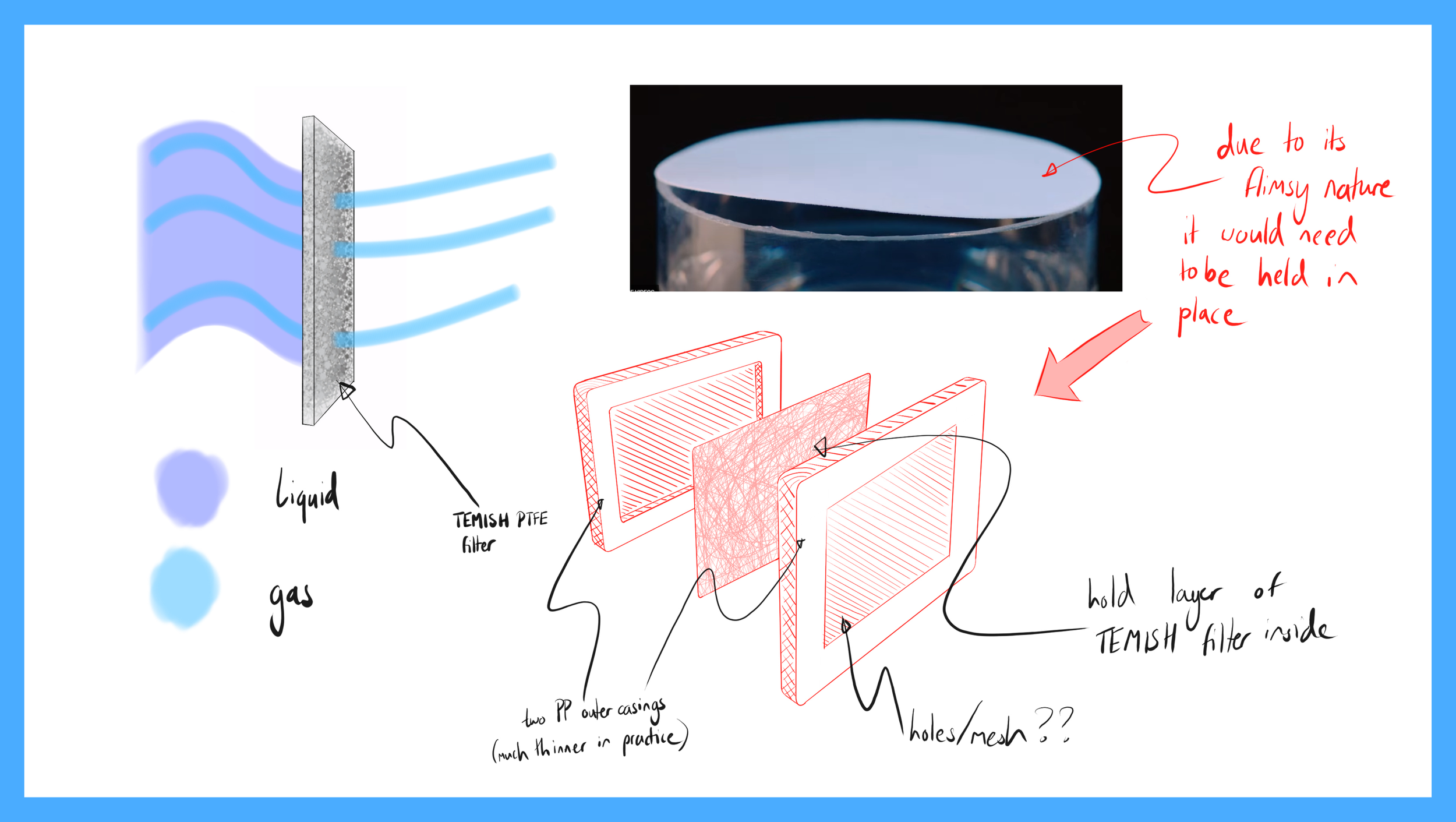

Materials Development

Manufacturing Development

CAD Changes

Extra Models

A final aspect that was not on show through these three projects was some other forms of modelling. The other types of modelling that I have developed throughout my time include: foam modelling, card modelling and prototype modelling; and these can all be seen below…

Foam modelling was generally used in earlier stages of developing to test on how form feels/looks and to develop a better understanding on how the design works in three dimensions.

Card modelling was a method used only for quick mock ups in order to see my designs in 3D and to test as many ideas as possible due to the quick nature of producing the models.

Prototype modelling is done usually near the end of the development to get feedback from potential users on my design. Mostly these were produced via 3D printing as it offers a 1:1 model that shows off my designs to their best ability.